System for measuring and controlling rotating speed

A speed measurement and control system technology, applied in the direction of electric speed/acceleration control, etc., to achieve the effect of reducing connection gap, convenient control, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Attached below Figure 1-7 The present invention is described in detail with specific examples.

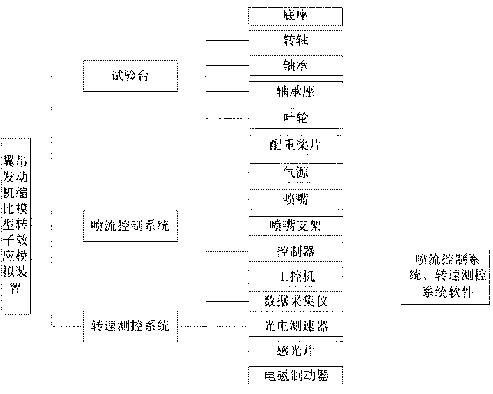

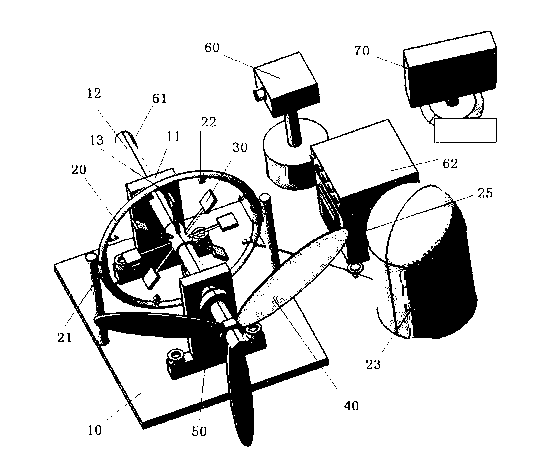

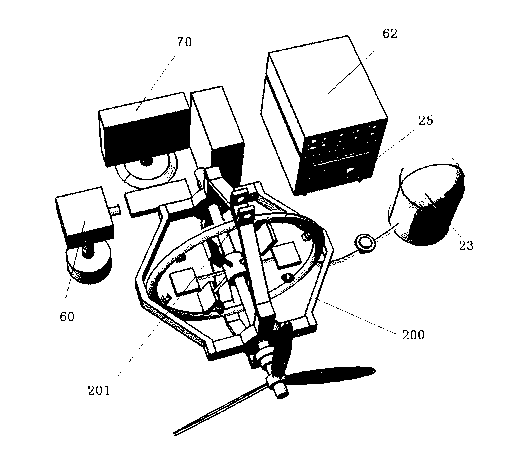

[0017] figure 1 with figure 2 It is the structural composition diagram and schematic diagram of the first embodiment of the rotor effect simulation device of the scaled model of the wing crane engine of the present invention, which is composed of Figure 1~2 It can be seen that the structure of the simulation device is composed of three parts: the test bench, the jet flow control system, and the rotational speed measurement control system; The system includes: nozzle bracket (nozzle ring bracket 20, nozzle side bracket 21), nozzle 22, air source 23, regulating valve 24, controller 25, industrial computer 70; the speed measurement control system includes: photoelectric speedometer 60, photosensitive sheet 61, Data acquisition instrument 62, electromagnetic brake 50, industrial computer 70.

[0018] The test bench is a base 10 with a slideway, the base 10 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com