Circuit structure for controlling infrared remote control emission

A circuit structure and infrared remote control technology, applied in non-electrical signal transmission systems, signal transmission systems, instruments, etc., can solve the problems of unavoidable procurement costs of triodes and current-limiting resistors, occupying processing capacity, and unfavorable cost control, etc., to achieve Stable and reliable working performance, low power consumption, flexible effect development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

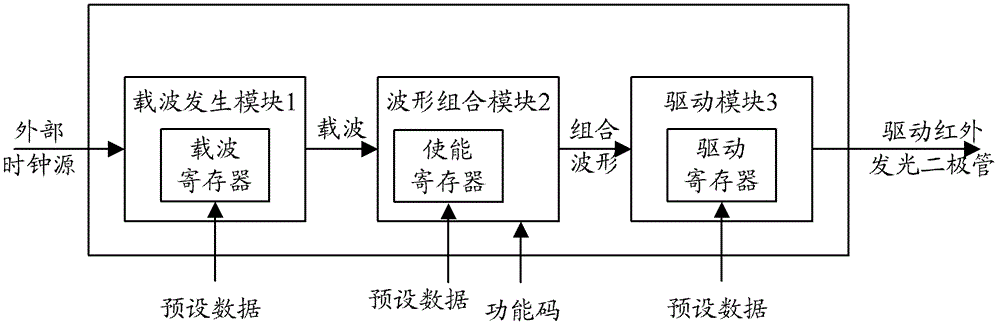

[0029] see Figure 1 to Figure 4 As shown, the circuit structure for controlling infrared remote control emission, wherein the circuit structure includes:

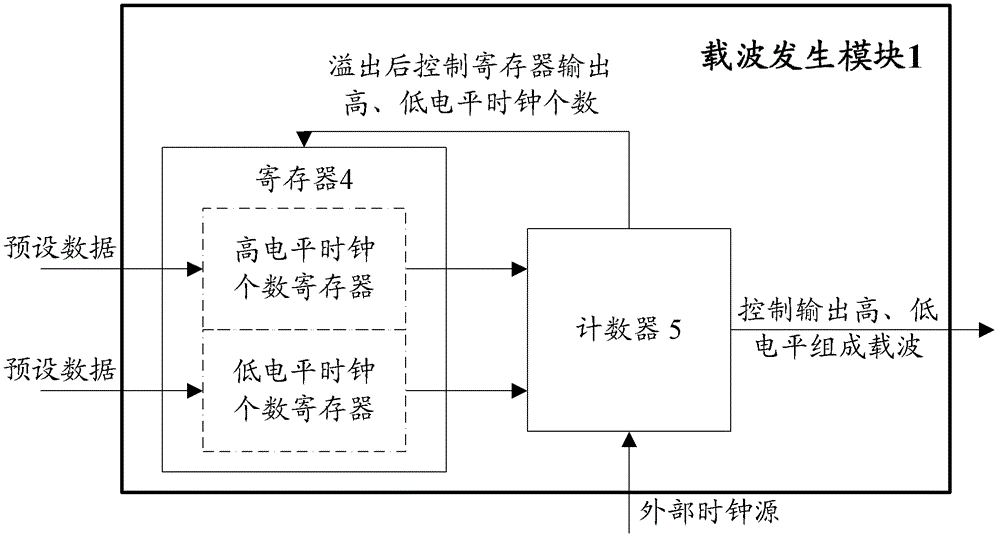

[0030] (1) The carrier generation module controls the high and low level length of the carrier according to the preset value; including:

[0031] ●Register, which saves the high and low level length data information of the preset carrier; the register includes a high level clock number register and a low level clock number register;

[0032] The counter is connected to the register and is used to control the number of high and low level clocks of the carrier according to the preset value;

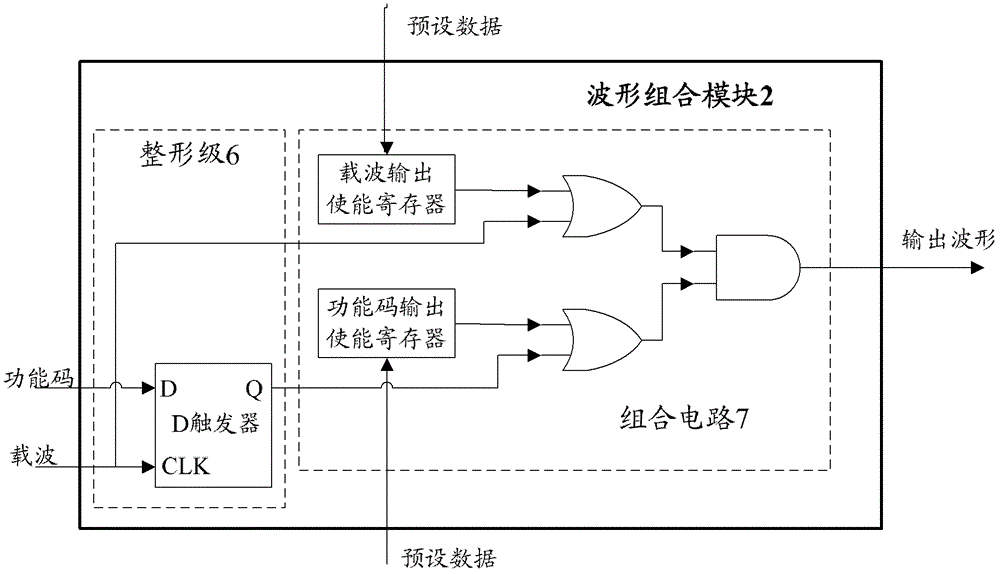

[0033] (2) waveform combination module, connected with the carrier generation module, used to combine carrier and function code, and select only transmitting carrier or only transmitting function cod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com