Semiconductor interconnect structure and method of forming

An interconnection structure and semiconductor technology, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., can solve the problems of semiconductor manufacturing process mismatch, high production cost, and complex formation process, etc., to avoid Effects of breaking, increasing mechanical strength, and preventing shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

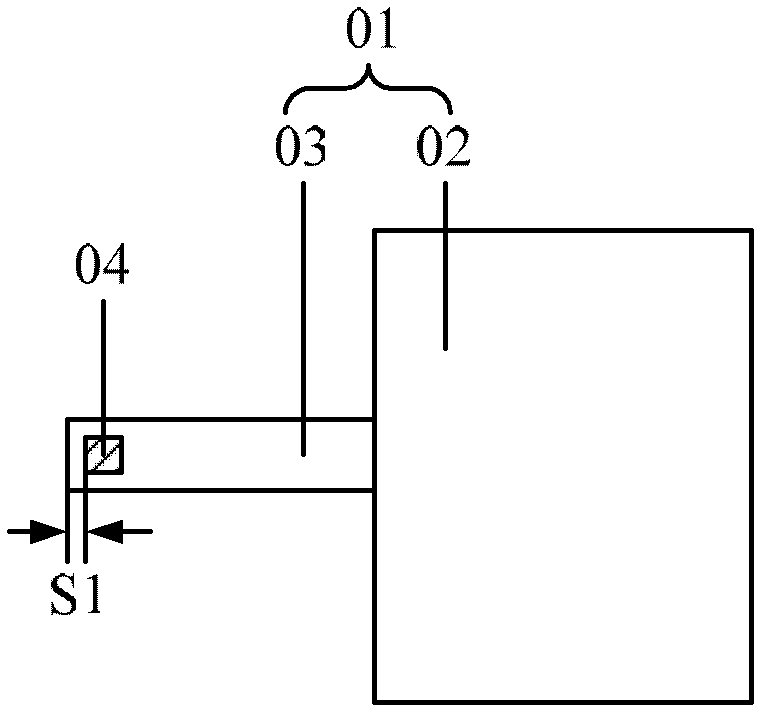

[0038] Due to the complex formation process of the prior art mentioned in the background art, which does not match the existing semiconductor manufacturing process, and high production costs, the inventors found that the vacancies used to form voids are in the form of through-silicon vias and metal interconnection layers. The contact position is formed in the circular metal layer at the center of the circle. If the area of the metal interconnection layer is small, the number of vacancies formed by tensile stress is small, and the probability of forming voids will be greatly reduced. Therefore, the invention proposed a semiconductor interconnection structure, please refer to image 3 , is a schematic structural diagram of the semiconductor interconnection structure of this embodiment, including: a metal interconnection layer 01, the metal interconnection layer 01 includes a metal layer 02 and a metal protrusion 03 connected to the edge of the metal layer 02; The conductive pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com