Built-in permanent magnet motor

A permanent magnet, built-in technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, synchronous motor with stationary armature and rotating magnet, etc., can solve unexpected parasitic effects, quadrature Reduce inductance, increase high-order harmonics, etc., to improve the effect of excessive cogging torque and suppress high-order harmonics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to describe the technical content of the present invention in detail, it will be described in detail below in conjunction with the implementation manners and accompanying drawings.

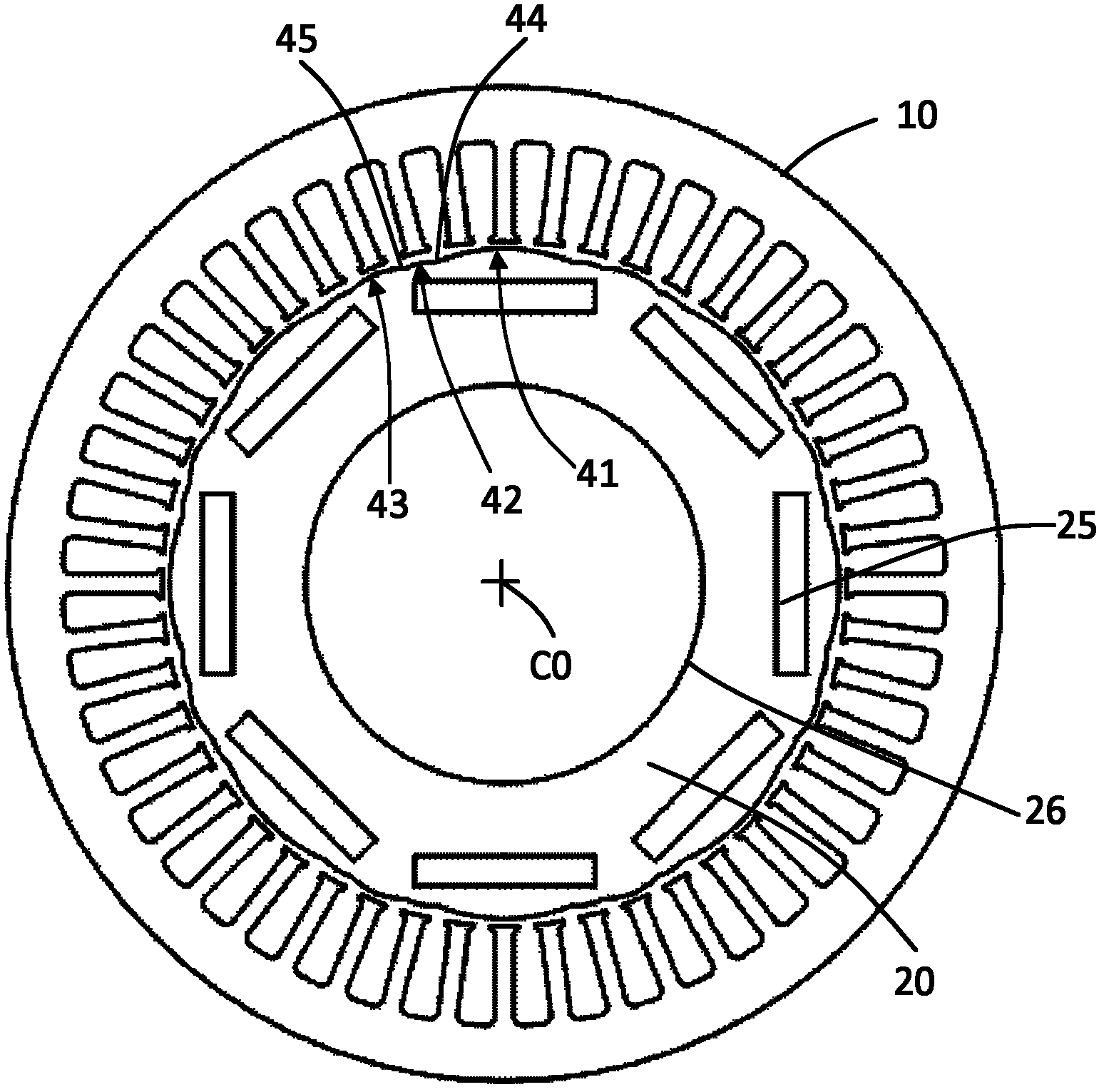

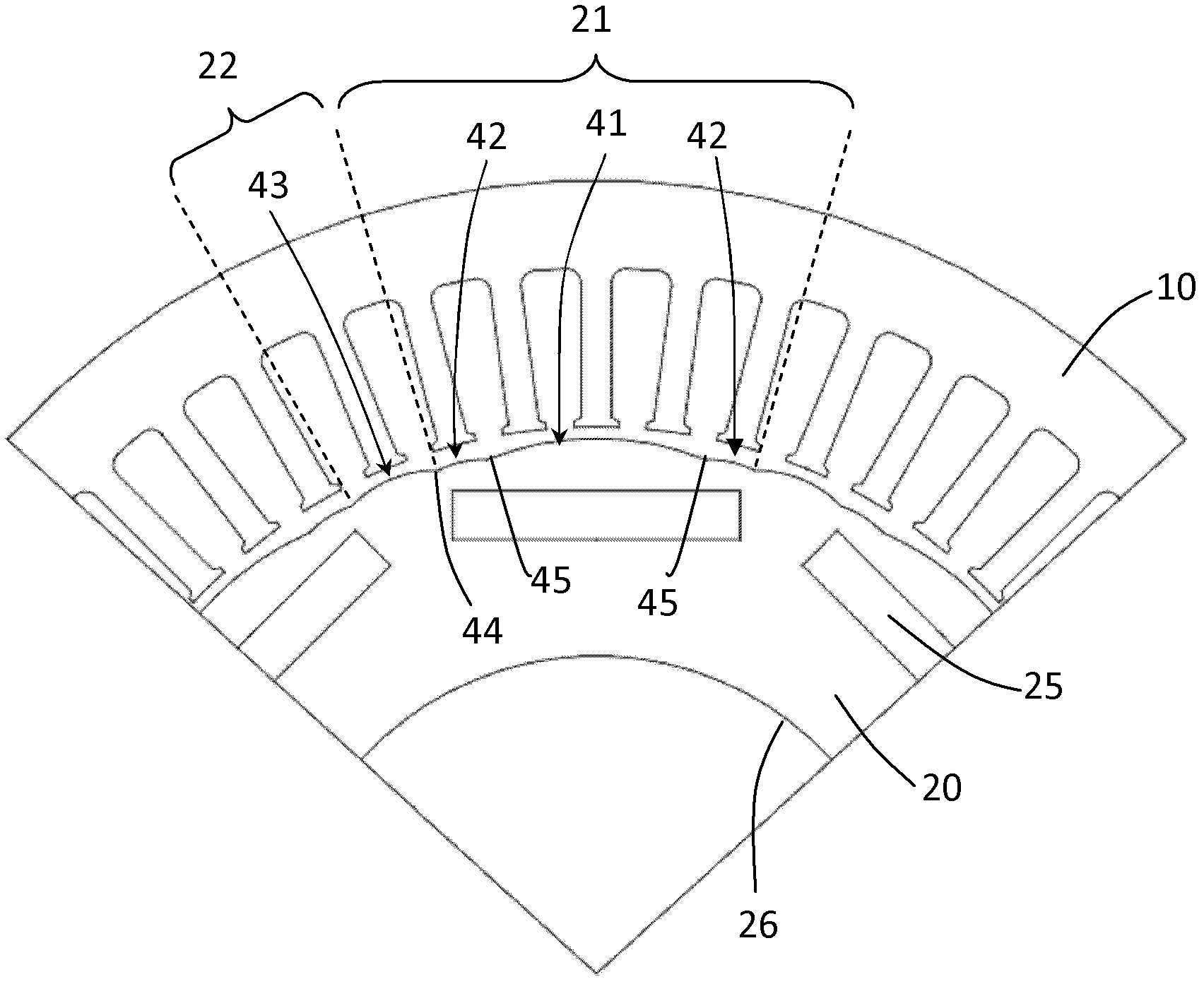

[0033] Such as figure 2 with image 3 As shown, the present invention is described with the end view of the motor stator and rotor, including a stator 10, a rotor 20, a plurality of magnet slots 25 for the built-in permanent magnets, and the center of the rotor 20 for the rotation axis (not shown in the figure) Show) through the shaft hole 26 of the pivot.

[0034] image 3 yes figure 2 A partial enlargement of the figure to clearly show the shape of the outer edge of the rotor. In the present invention, the outer edge of the rotor of the motor is planned with a plurality of main magnetic pole faces 21 and inter-pole faces 22, and each inter-pole face 22 is between two adjacent main magnetic pole faces 21; the main magnetic pole faces 21 and the interpolar pole surface 22 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com