Air energy soil-thermal storage heating and cooling device for fruit and vegetable plastic sheds or greenhouses in cold areas

A cold area, air energy technology, applied in the field of air energy soil heat storage heating and cooling devices, can solve the problems of unfavorable plant growth, inability to provide cooling and cooling, high maintenance costs, etc., and achieve the effect of reasonable recycling and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

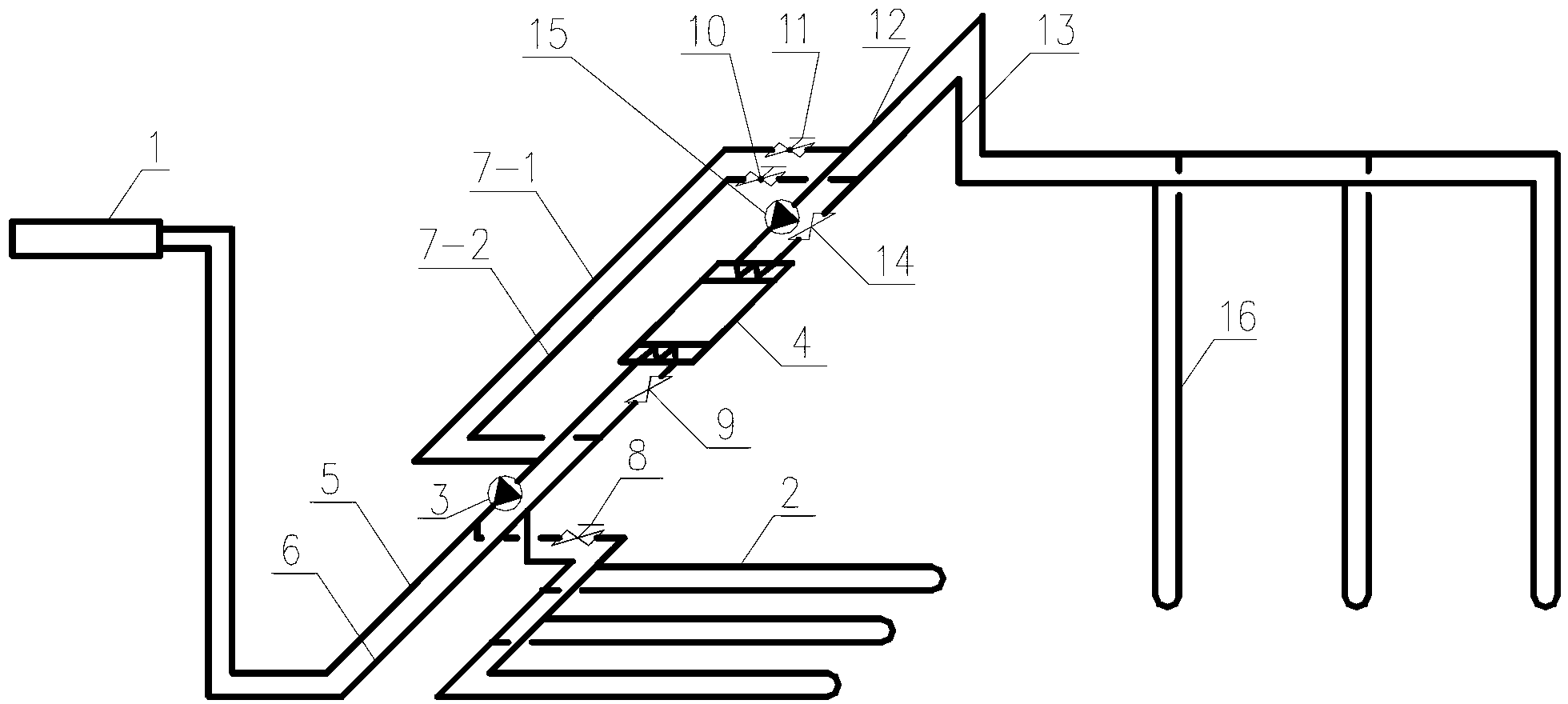

[0012] Specific Embodiment 1: This embodiment is described with reference to FIG. 1. The device in this embodiment includes a fan coil unit 1, a second circulation pump 3, a heat pump unit 4, a high temperature side water supply pipe 5, a high temperature side return water pipe 6, a first Bypass pipe 7-1, second bypass pipe 7-2, first valve 9, second solenoid valve 10, third solenoid valve 11, low temperature side water supply pipe 12, low temperature side return water pipe 13, second valve 14, The first circulating pump 15 and the vertical U-shaped buried pipe heat exchanger 16, the outlet end of the vertical U-shaped buried pipe heat exchanger 16 communicates with the inlet end of the low-temperature side water supply pipe 12, and the outlet ends of the low-temperature side water supply pipe 12 are respectively One end of the first bypass pipe 7-1 communicates with the inlet end of the first circulation pump 15, and the other end of the first bypass pipe 7-1 communicates with...

specific Embodiment approach 2

[0017] Specific embodiment two: this embodiment is described in conjunction with Fig. 1, and the device of this embodiment also includes a horizontal buried heating pipe 2 and a first electromagnetic valve 8, and the inlet end of the horizontal buried heating pipe 2 communicates with the high temperature side water supply pipe 5, The outlet end of the horizontal buried heating pipe 2 communicates with the return pipe 6 on the high temperature side, and the inlet part of the horizontal buried heating pipe 2 is provided with a first electromagnetic valve 8, when the temperature of the soil reference point at the root of the ground plant in the greenhouse or greenhouse is lower than its limit temperature, the first electromagnetic valve 8 is opened, and the heat medium heats the surface layer soil through the horizontal buried heating pipe 2, and when the temperature of the soil layer reaches the set temperature value, the electromagnetic valve 8 is closed. The heat pump unit 4 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com