Production method of boiled oil instant chafing dish

A production method and hot pot technology, applied in food preparation, food science, application, etc., can solve problems such as high cholesterol content, unhygienic processing, and easy production of harmful substances, and achieve simple processing procedures, short processing time, and shortened cooking The effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

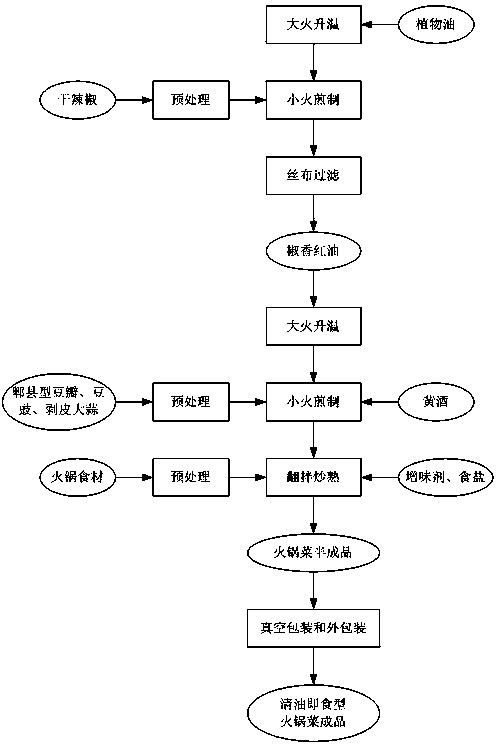

Image

Examples

Embodiment Construction

[0021] The production method of clear oil ready-to-eat hot pot dishes of the present invention adopts main raw materials such as vegetable oil, dried chili pepper, Chinese prickly ash, Pixian type watercress, tempeh, rice wine, peeled garlic, old ginger and compound spices, together with hot pot ingredients, through a special pre-cooking method. After the processing, preparation of peppery red oil, frying and seasoning processing, the hot-packing process is used for vacuum packaging to obtain the finished product of clear oil instant hot pot dish. The selected raw materials and hot pot ingredients should be carefully screened as much as possible to ensure the use of high-quality raw materials that are free from diseases, insect pests, and spoilage, and to ensure the quality of the produced clear oil ready-to-eat hot pot dishes.

[0022] After screening and ensuring high-quality raw materials and hot pot ingredients, and determining the formula of raw materials according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com