A heat source supply method and device for scr denitrification reducing agent urea pyrolysis

A technology of reducing agent and urea is applied in the field of preparation of reducing agent for flue gas denitration, which can solve the problems of high energy consumption and high operating cost in urea pyrolysis, and achieve the effects of small impact, saving operating cost, reducing energy consumption and plant electricity consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following non-limiting examples illustrate the invention.

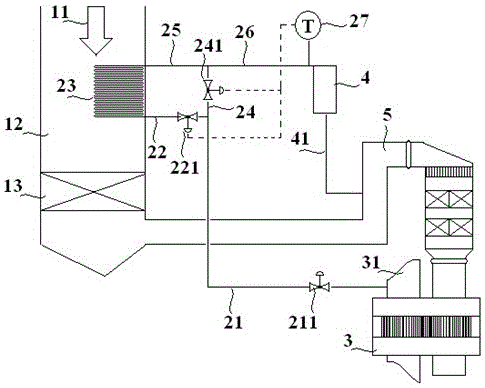

[0026] like figure 1 As shown, the urea pyrolysis air pipeline 21 leads the hot primary air 31 of the air preheater 3 (accounting for 0.5-5% of the total air volume, temperature 0-400°C, pressure 10±5kPa), and passes through the air-tracheal heat exchanger The inlet pipe 22 enters the gas-gas tube heat exchanger 23, and is heated by the boiler flue gas 11, and the air in the gas-gas tube heat exchanger 23 is heated to a temperature equivalent to the temperature of the flue gas, meeting the urea pyrolysis temperature of 400°C-900°C . The heated air enters the urea pyrolysis reactor 4 through the outlet pipe 25 of the gas-air pipe heat exchanger and the inlet pipe 26 of the urea pyrolysis reactor. In the urea pyrolysis reactor 4, the urea solution is pyrolyzed to generate ammonia gas mixture , the ammonia gas mixture enters the denitration reaction device 5 through the urea solution pyrolysis product pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com