A kind of production device and production method of liquid thiram potassium

A production method, thiram potassium technology, applied in the field of liquid thiram potassium production equipment, can solve problems such as economic loss and poor safety, and achieve the effects of improved raw material conversion rate, simple operation, and improved production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

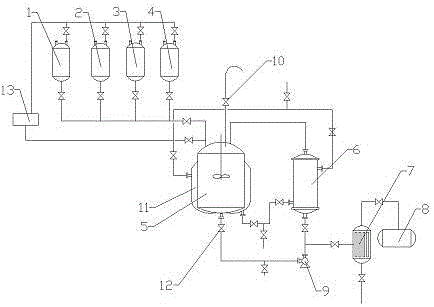

[0048] Example 2, such as figure 1 Shown, a kind of production device of liquid thiram potassium comprises reactor 5, and the top of described reactor 5 is connected with dimethylamine elevated tank 1, sulfur dioxide elevated tank 2, potassium hydroxide elevated tank 3 and soft water respectively by pipeline The head tank 4, the bottom of the reactor 5 is connected with a reactor discharge valve 12, and the reactor discharge valve 12 is sequentially connected with a filter 7 and a finished product storage tank 8 through pipelines.

[0049] The outside of the reactor 5 is provided with a reactor jacket and an inner cooling coil 11, and the reactor jacket and the inner cooling coil 11 are communicated with a cooler 6 through pipelines, and its purpose is to cool the materials in the reactor. Cooling, together with the synergistic effect of reactor jacket cooling and reactor inner coil cooling, is sufficient to remove the reaction heat and shorten the reaction time;

[0050] A c...

Embodiment 3

[0063] Example 3, such as figure 1 Shown, a kind of production device of liquid thiram potassium comprises reactor 5, and the top of described reactor 5 is connected with dimethylamine elevated tank 1, sulfur dioxide elevated tank 2, potassium hydroxide elevated tank 3 and soft water respectively by pipeline The head tank 4, the bottom of the reactor 5 is connected with a reactor discharge valve 12, and the reactor discharge valve 12 is sequentially connected with a filter 7 and a finished product storage tank 8 through pipelines.

[0064] The outside of the reactor 5 is provided with a reactor jacket and an inner cooling coil 11, and the reactor jacket and the inner cooling coil 11 are communicated with a cooler 6 through pipelines, and its purpose is to cool the materials in the reactor. Cooling, together with the synergistic effect of reactor jacket cooling and reactor inner coil cooling, is sufficient to remove the reaction heat and shorten the reaction time;

[0065] A c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com