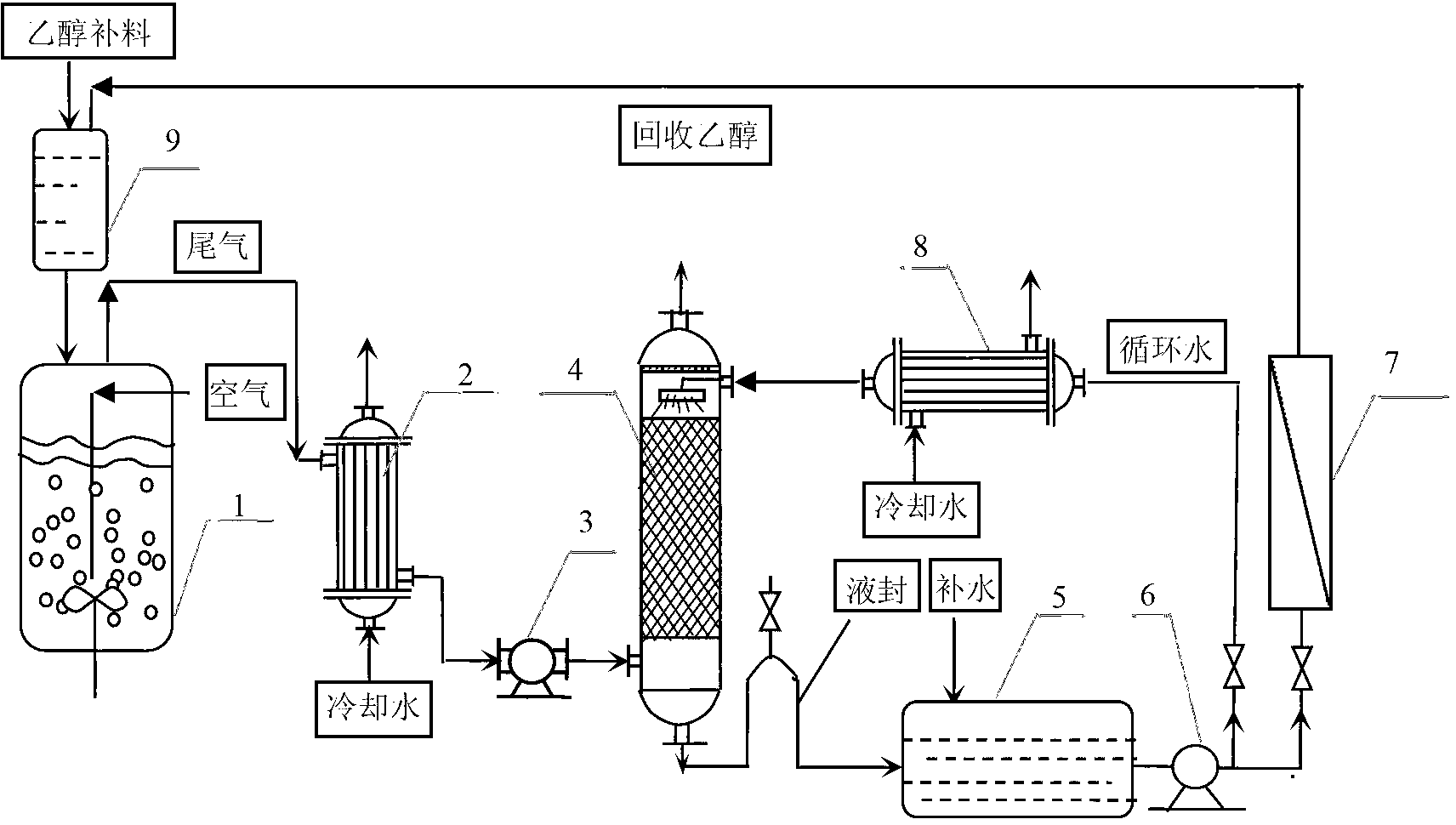

Vinegar liquid state fermentation device and working method thereof

A technology for liquid fermentation and vinegar, applied in the field of optimized treatment and reuse devices and recycling, can solve the problems of secondary pollution of condensate, large operation energy consumption, complicated equipment, etc. The effect of raw material consumption and improvement of recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

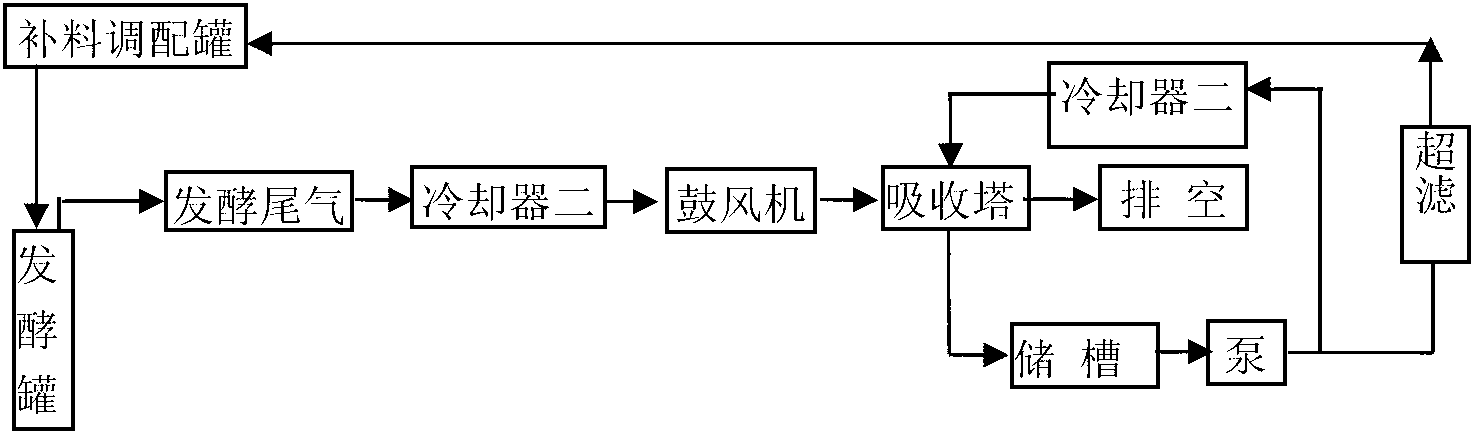

[0038] A 5-liter ventilated fermenter is used, with an initial alcohol content of 8% (V%), a charging volume of 3 liters, a fermentation temperature of 33°C, and a ventilation rate of 1.5L / min. The packed tower with a height of 30cm absorbs, the spray water flow rate is 5 liters / min, the spray water temperature is 8°C, and the recovered ethanol after 24 hours of fermentation is 10.3% (V%) of the initial ethanol in the fermenter.

Embodiment 2

[0040] 100 liters of self-priming fermentation is adopted, the initial fermentation liquid alcohol concentration is 8%, the filling volume is 70 liters, the fermentation temperature is 33 ℃, the tail gas is cooled by 15 ℃ water, and then after passing through a blower with a power of 138W and an air volume of 100L / min, it enters the diameter The packed tower with a height of 40 cm and a height of 80 cm absorbs, the spray water flow rate is 100 liters / min, the spray water temperature is 15°C, and after 24 hours of fermentation, the recovered ethanol amount is 8.3% of the initial ethanol amount in the fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com