Cleaning agent for locally cleaning ironmaking blast furnace water-cooling wall in on-line loading manner and application thereof

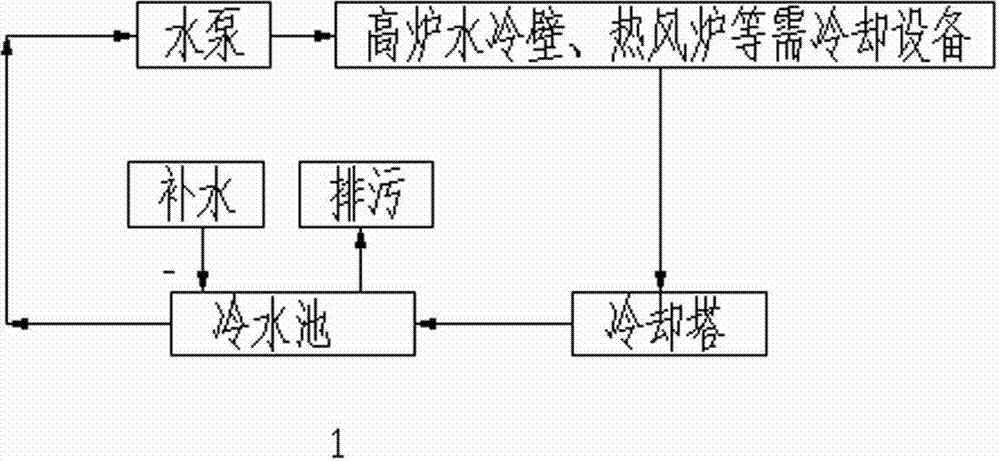

A technology for iron-making blast furnaces and water-cooled walls, applied in the field of chemical cleaning, which can solve problems such as long process pipelines, high costs, and large cleaning doses, and achieve the effects of restoring heat exchange efficiency, improving service life, and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

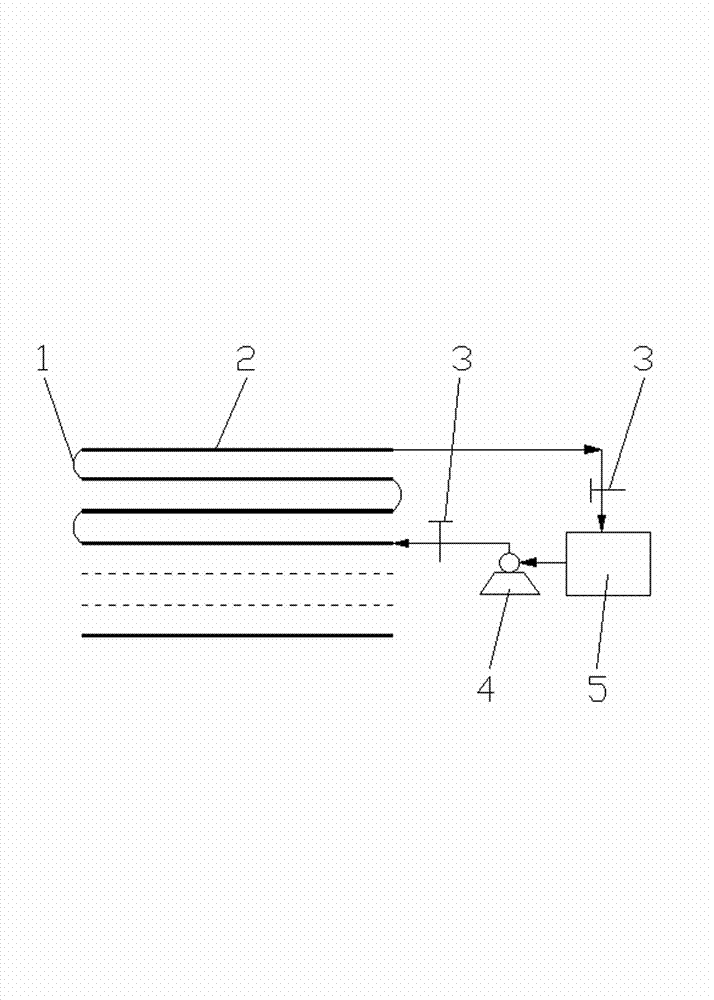

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

[0024] A cleaning agent for on-line local cleaning of the water wall of an ironmaking blast furnace with load, its components and weight ratio are: hydrochloric acid (according to HCl): 15-30, sulfamic acid: 10-20, citric acid: 10-20 20. Hydroxyethylidene diphosphonic acid (HEDP): 5-15, aminotrimethylene phosphonic acid (ATMP): 5-15, corrosion inhibitor: 0.2-1.0, water: 30-40. The components of the corrosion inhibitor and their weight proportions are: tolyltriazole: 3-13, urotropine: 37-47, aniline: 15-25, potassium thiocyanate: 10-20 , Sodium hexametaphosphate: 10-20.

[0025] Application of the cleaning agent for on-line local cleaning of the water wall of the ironmaking blast furnace above: first slowly add the cleaning agent produced according to the formula into the cleaning box, the concentration of the cleaning agent used is 5-30% by mass, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com