Multi-functional casing pipe part and anchor rod construction method using same

A construction method and multi-functional technology, applied in the direction of infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of economic waste, soil mechanical properties reduction, deviation, etc., to achieve corrosion prevention, high construction efficiency, and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

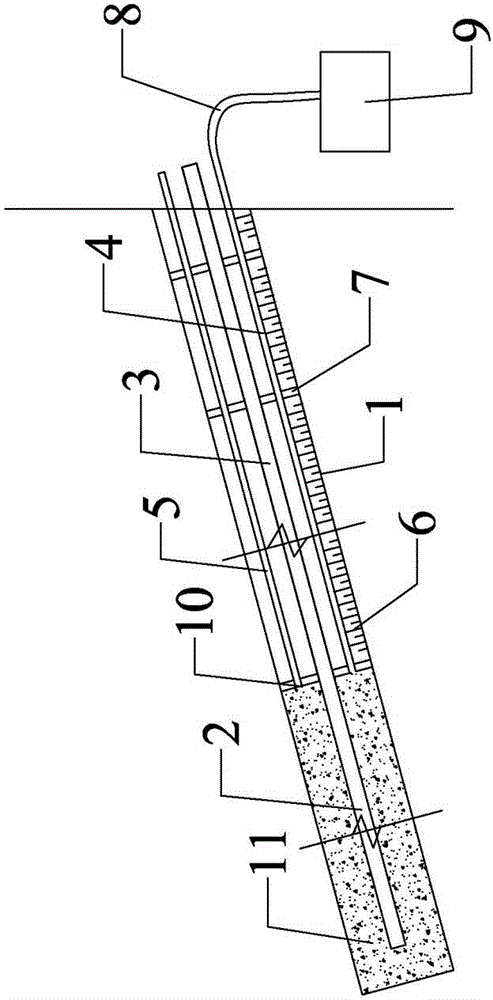

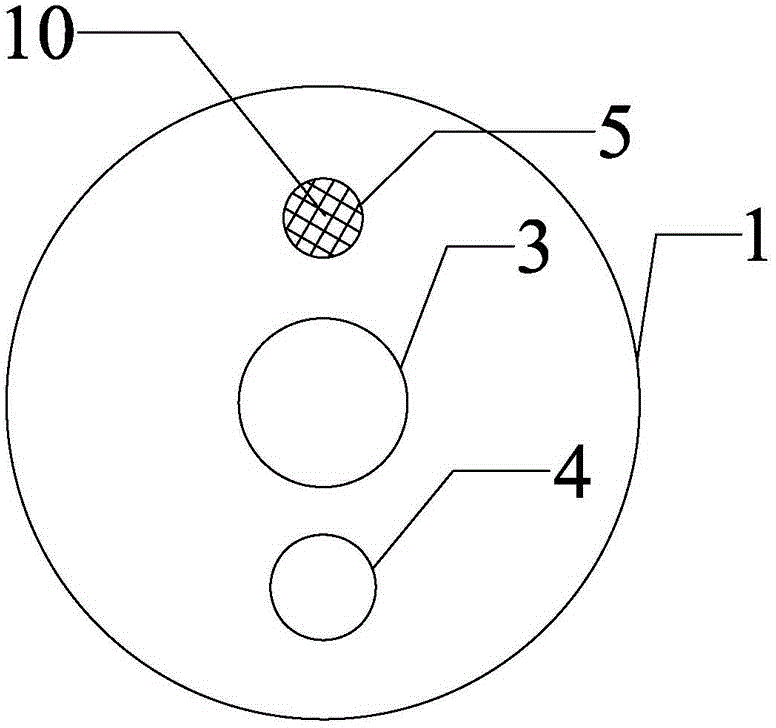

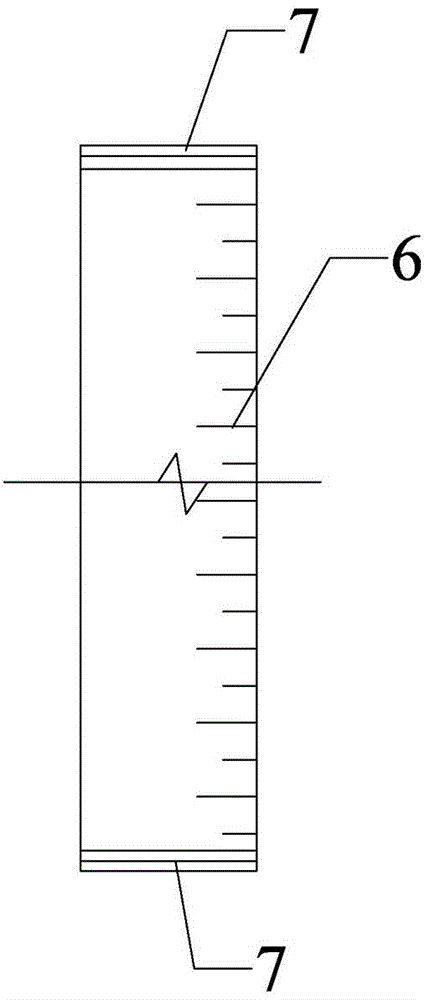

[0021] Such as figure 1 , figure 2 As shown, this embodiment is a multifunctional casing fitting, which is spliced by several cylindrical units 1, and each cylindrical unit is provided with three channels along the axial direction, which are the anchor rod channel 3 and the grouting channel respectively. 4 and exhaust channel 5, wherein the anchor channel 3 is located at the center of the bushing fitting 1, the grouting channel 4 is located at the lower part close to the cylindrical unit 1, and the exhaust channel 5 is located at the upper part close to the cylindrical unit 1. Such as image 3 As shown, a scale 6 is set on the outer cylindrical surface of the cylinder unit 1, and the cylinder units 1 are connected by a slot 7. The length of each cylinder unit 1 can be prefabricated according to the design requirements by 1 meter or 0.5 meters, or can be Set different sizes according to specific requirements.

[0022] In this example, the size of the anchor rod channel 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com