Mould support method of foundation pit basement haunch shearing wall

A formwork support method and shear wall technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as difficult to meet construction technical requirements and short construction period, and achieve low construction difficulty and short construction period , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

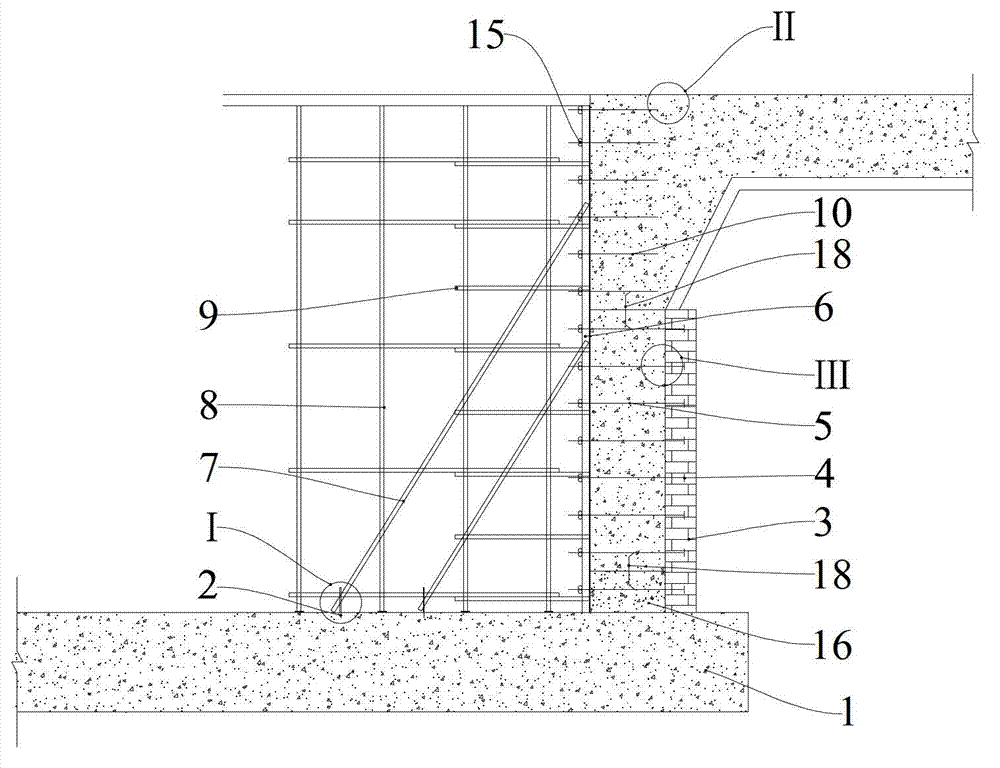

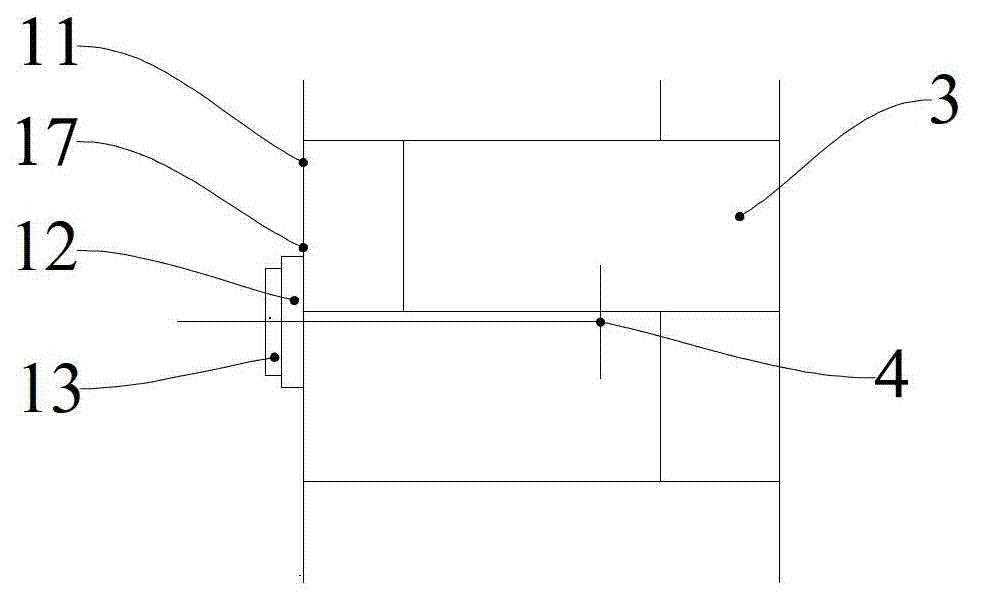

[0024] see figure 1 , the foundation pit basement of the present invention adds the formwork method of axillary shear wall, comprises the following steps:

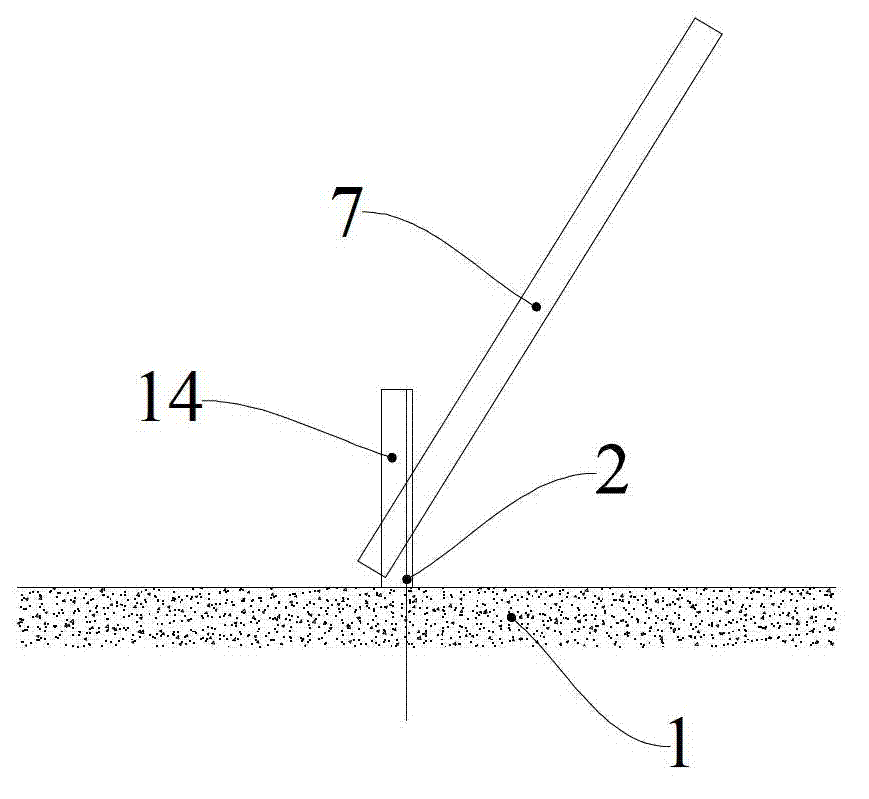

[0025] S1: The basement floor 1 and the upturned shear wall 16 arranged on the upper surface of the basement floor 1 are integrally cast, and the steel bar head 2 is pre-embedded on the basement floor 1;

[0026] Specifically, the basement floor 1 is integrally casted, and the upturned shear wall 16 with a height of 300 mm to 500 mm arranged on the upper surface of the basement floor 1 is formed by casting. part, and a steel plate waterstop 18 for waterproofing is fixed in the middle of the top of the upper shear wall 16. While pouring the basement floor 1 and the upturned shear wall 16, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com