Turbine cooling system

A technology for cooling systems and turbines, applied in mechanical equipment, engine components, machines/engines, etc., to solve problems such as the overall performance reduction of turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] As used in this specification, the terms module and submodule refer to an Application Specific Integrated Circuit (ASIC), an electronic circuit, a processor (shared, dedicated or grouped) and memory, a combination of Logic circuits and / or other suitable components that provide the described functionality.

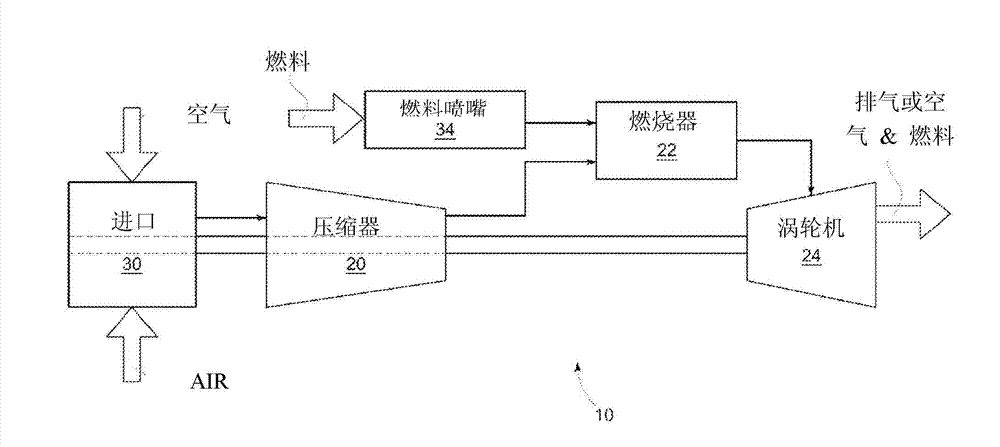

[0019] figure 1 A schematic diagram of an exemplary power generation system indicated by reference numeral 10 is shown. Power generation system 10 is a gas turbine system having compressor 20 , combustor 22 and turbine 24 . Air enters power generation system 10 through an air inlet 30 located in compressor 20 and is compressed by compressor 20 . The compressed air is then mixed with fuel through fuel nozzles 34 located in the end cover (not shown) of the combustor 22 . Fuel nozzles 34 inject an air-fuel mixture into combustor 22 at a ratio for combustion. Combustion produces hot, pressurized exhaust gas that drives blades (not shown) located within turbine 24 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com