Scale structure type linear dynamic pressure air bearing and its design method

A technology of dynamic pressure air bearing and scaling structure, applied in the direction of bearing, shaft and bearing, mechanical equipment, etc., can solve the problems of aerodynamic instability and insufficient load, achieve high reliability, increase stability, improve stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

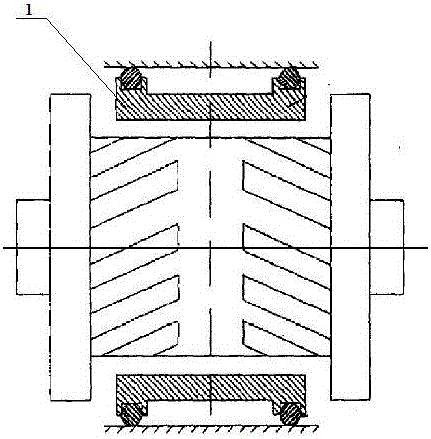

[0024] A linear dynamic pressure air bearing with a scaling structure, which consists of: a bearing body 1, the inner surface of the bearing body has a dynamic pressure structure, and the dynamic pressure structure is a scaling linear pressurized channel groove.

Embodiment 2

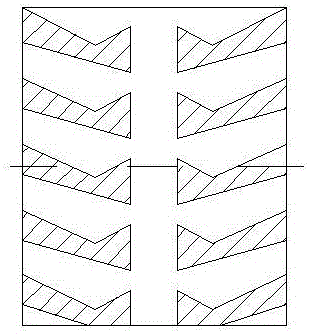

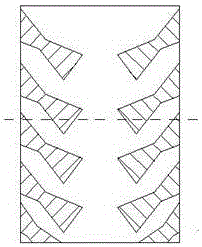

[0026] According to the zoom-shaped linear dynamic pressure air bearing described in Embodiment 1, the zoom-shaped linear pressurized runner groove is a Rafal nozzle-shaped linear pressurized runner groove or a fish head-shaped linear pressurized runner groove The groove line adjusts the radial and axial pressure distribution of the air film through different angles: when the angle between the groove line and the axial direction is large, the radial air film force is large; when the angle is small, the axial air force Membrane force is greater.

[0027] The slot width distribution of the fish head structure is asymmetrical, first decreases and then increases, and the slopes of the decrease and increase are different; the width of the Rafal nozzle structure is symmetrically distributed, first decreases and then increases. According to the characteristics of forming air film force, they are respectively applied to long bearings and short bearings.

Embodiment 3

[0029] A method for manufacturing a linear dynamic pressure air bearing with a scaling structure, the method includes the following parameters:

[0030] (1) Selection of air bearing body material, that is, according to the temperature, pressure and working medium of the air bearing application, reasonably select wear-resistant, high temperature resistant and self-lubricating performance materials as the material of the air bearing body;

[0031] (2) The hydrodynamic structure design of the air bearing, that is, according to the temperature, pressure and working fluid conditions of the air bearing application, as well as the journal rotation, whirl speed and load bearing properties, reasonably determine the shape of the scaling structure;

[0032] (3) The body structure design of the air bearing, that is, according to the load nature, stability requirements and working medium conditions of the air bearing, measures such as rubber rings, metal rubber and elastic composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com