Sampling tube fixing and sample ejecting device and sample ejector including same

A technology of sample ejector and sample cylinder, which is applied in the field of sample ejector accessories, can solve problems such as difficult handling and transportation, difficult cleaning of fixed parts, residual waste samples, etc., and achieves convenient and simple fastening and connection, easy maintenance and cleaning, and increased operation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

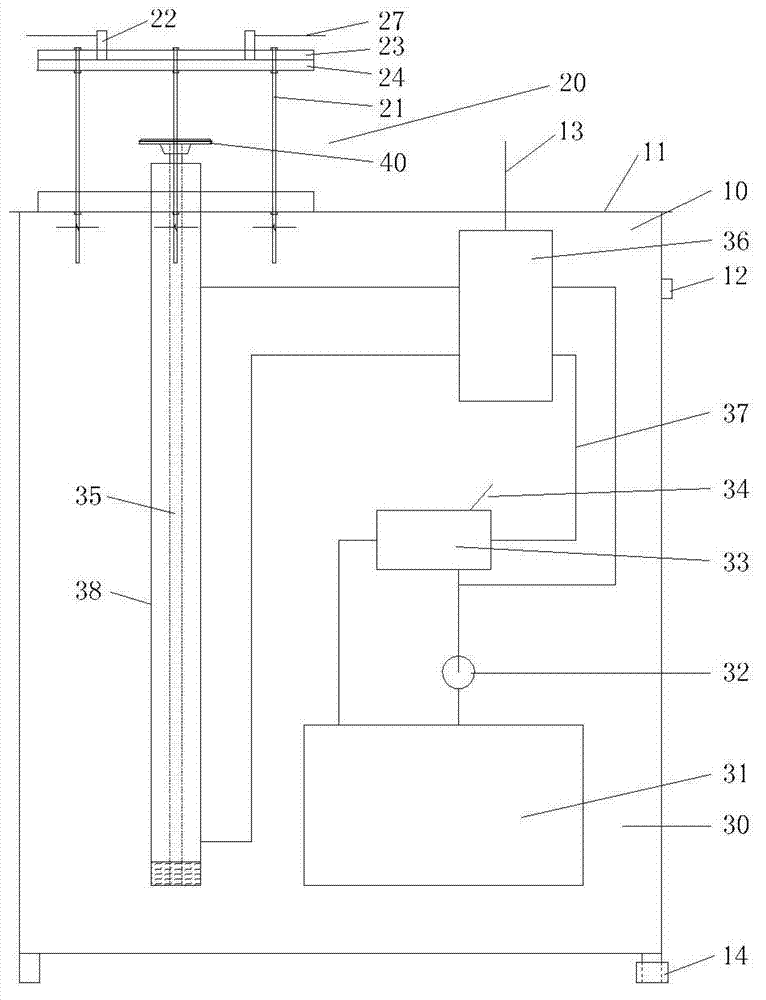

[0019] like figure 1 As shown, the cabinet (10) is a cuboid metal cabinet with a certain strength, and there are beams and longitudinal beams inside. A hydraulic lifting device (30) is placed in the cabinet space; a height-adjustable pad (14) is installed on the right front leg, and the remaining three legs are fixed in height; the power switch (12) is installed on the upper position on the right side of the cabinet (10) ; Steering valve handle (13) is fixed on the front position of the middle part on the right side of the top surface of the cabinet (10).

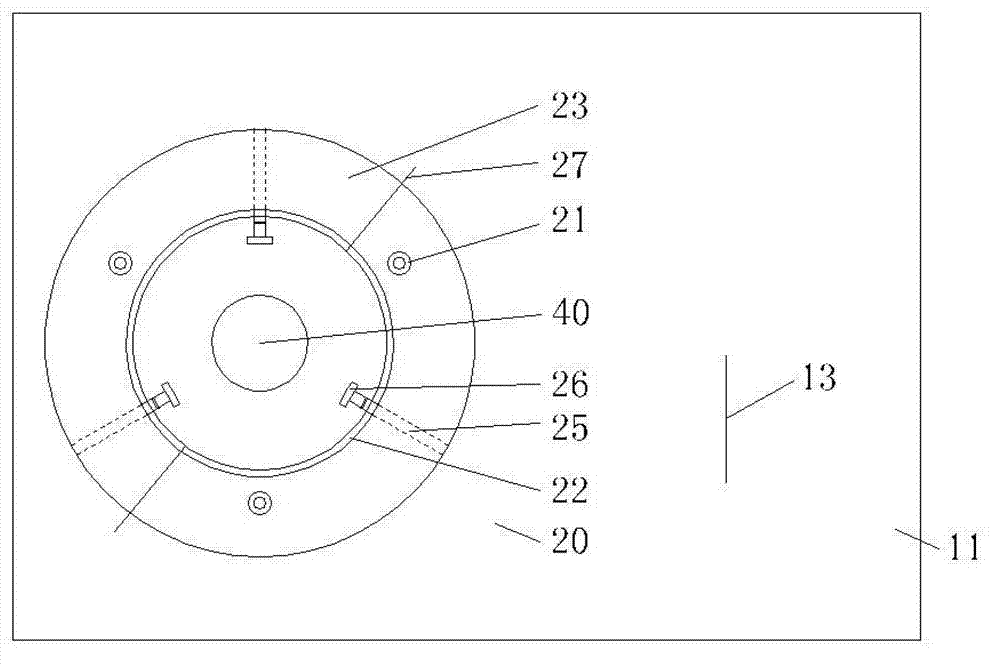

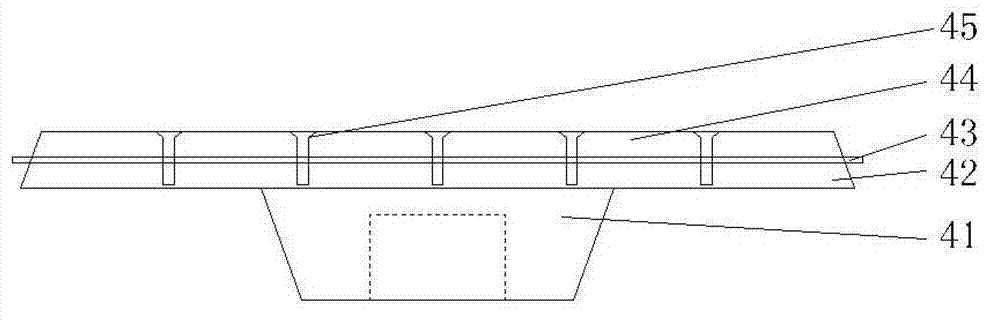

[0020] The sample cylinder fixing system (20) is composed of a height-adjustable counterforce support system and an adaptive locking system. The reaction force support is made up of three vertical columns (21) that can be adjusted in height, one end of which is fixed on the reinforced operatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com