Automatic material handling system based on programmable logic controller (PLC) control and control method thereof

A control method and material technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of long development and debugging time, affecting the production time of processing plants, etc., to meet the effect of timely response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

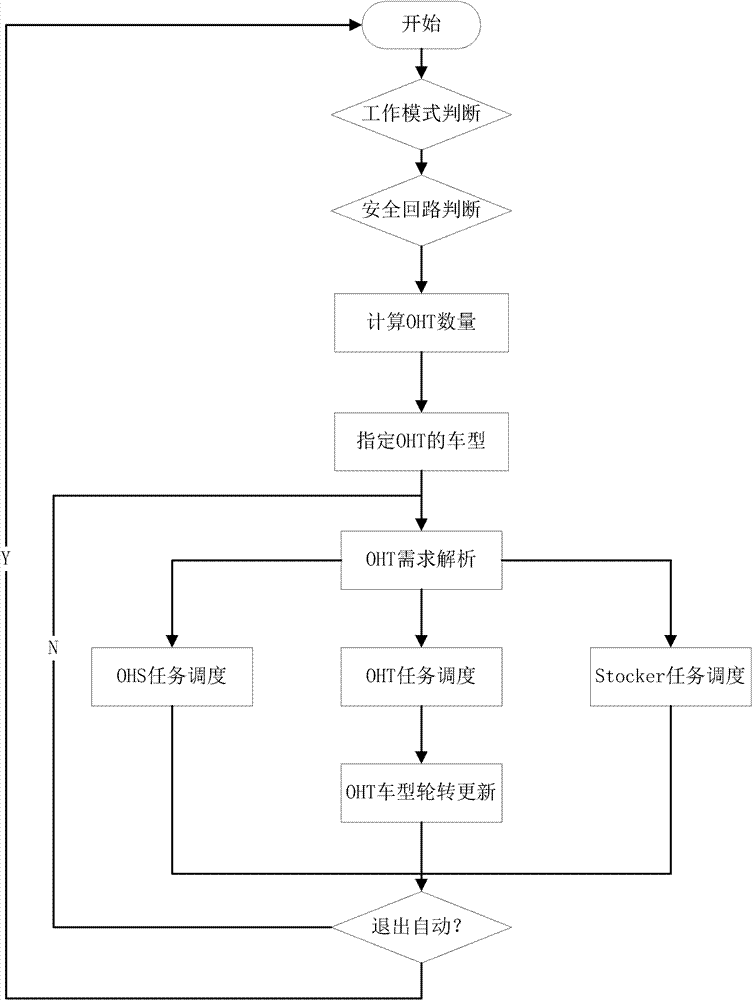

[0025] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

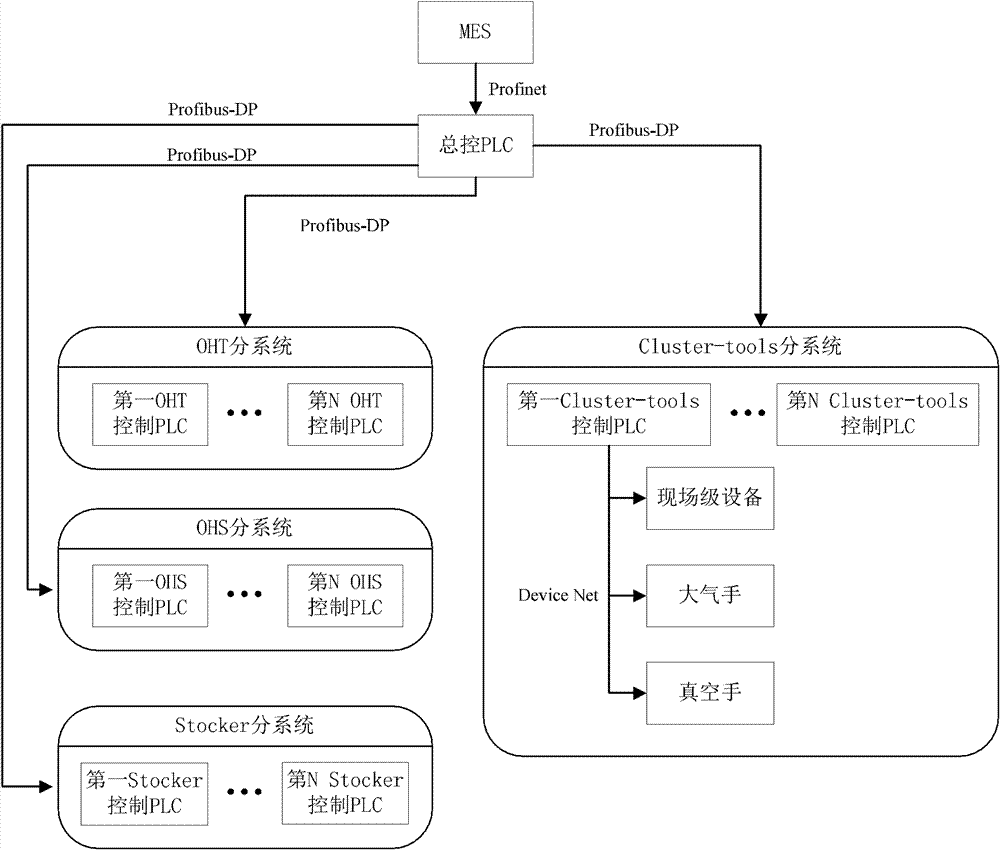

[0026] see figure 1 , the present invention relates to an automatic material handling system controlled by a programmable logic controller (PLC-Programmable Logic Controller), which includes a manufacturing execution subsystem (MES-Manufacturing Execution System), a master control PLC, an overhead crane (OHT- Over Head Hoist Transports) subsystem, overhead crane (OHS-Over Head Shuttles) subsystem, storage (Stocker) subsystem, processing unit subsystem, and machine (Cluster-tools) subsystem within the processing unit subsystem, of which ,

[0027] Overhead Hoist Transports (OHT-Over Head Hoist Transports) subsystem: including multiple overhead cranes (OHT) and one-to-one corresponding overhead crane (OHT) PLC controllers;

[0028] Overhea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com