Method for acquiring surface heat transfer coefficient of end winding of large-sized synchronous generator stator

A technology of surface heat dissipation coefficient and synchronous generator, which is used in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of high load, serious heating of end windings, and difficulty in determining the surface heat dissipation coefficient of end windings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

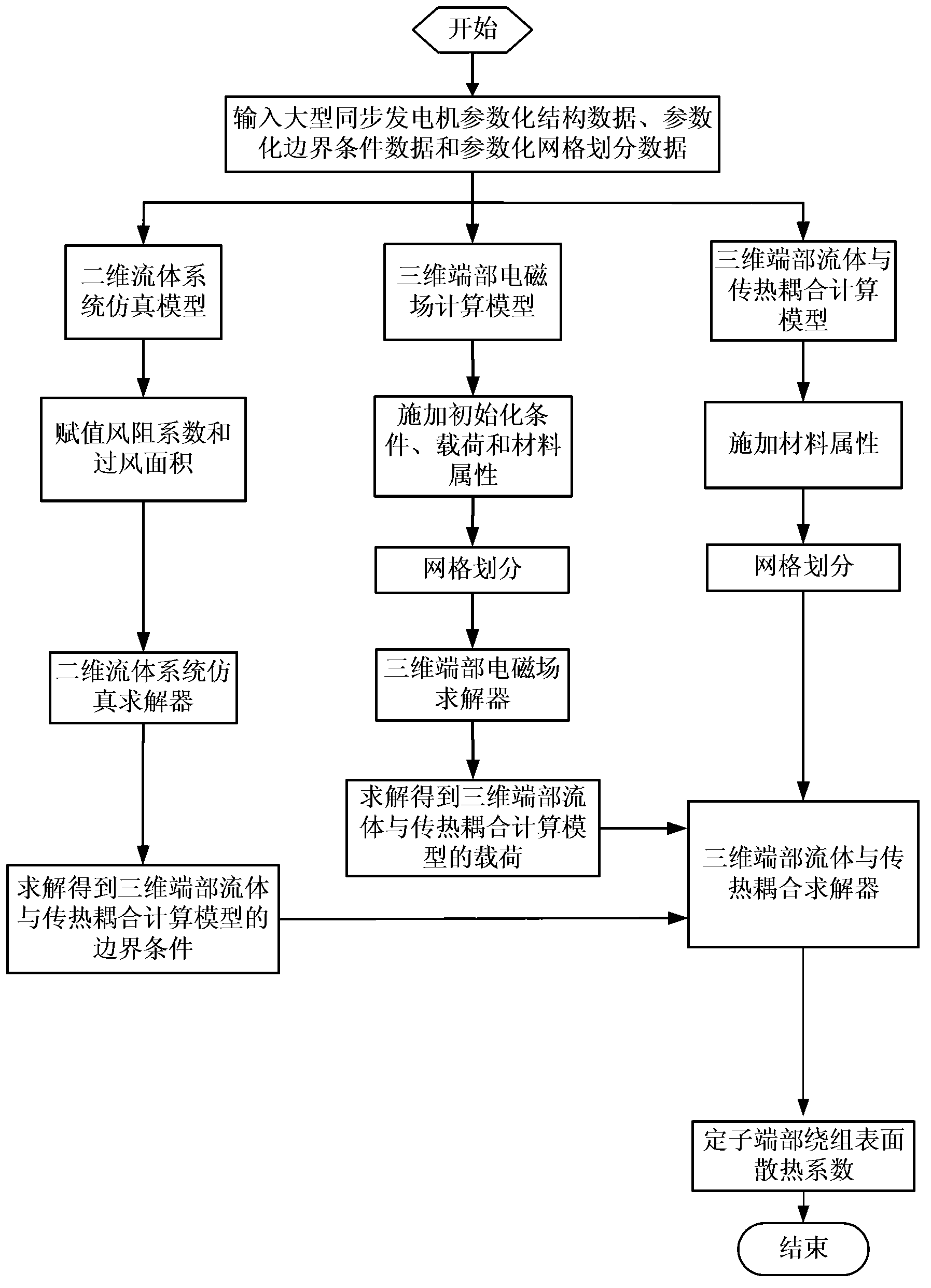

[0068] Specific implementation mode one: the following combination figure 1 Describe this embodiment, the method for obtaining the surface heat dissipation coefficient of the stator end winding of the large-scale synchronous generator described in this embodiment, it includes the following steps:

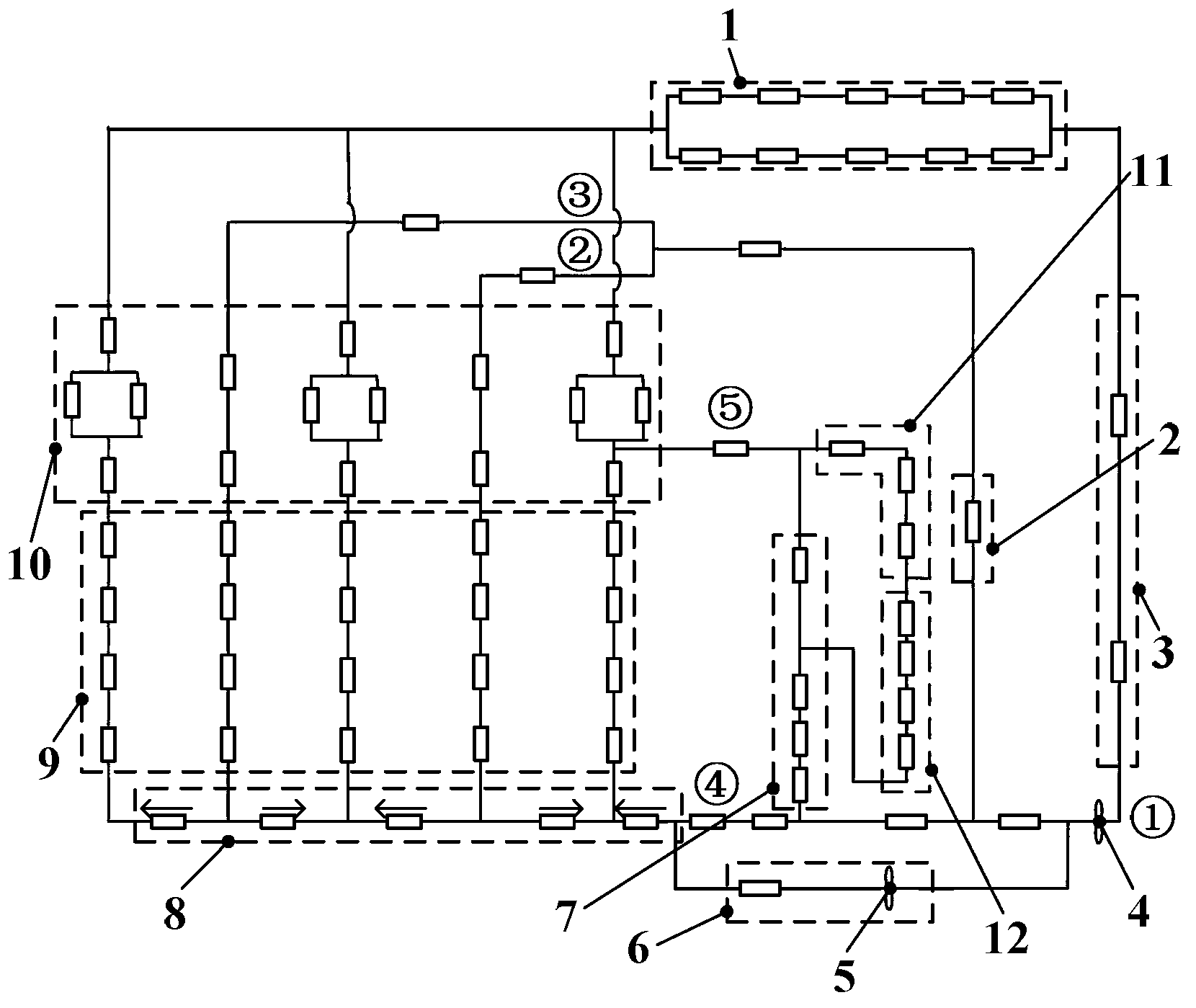

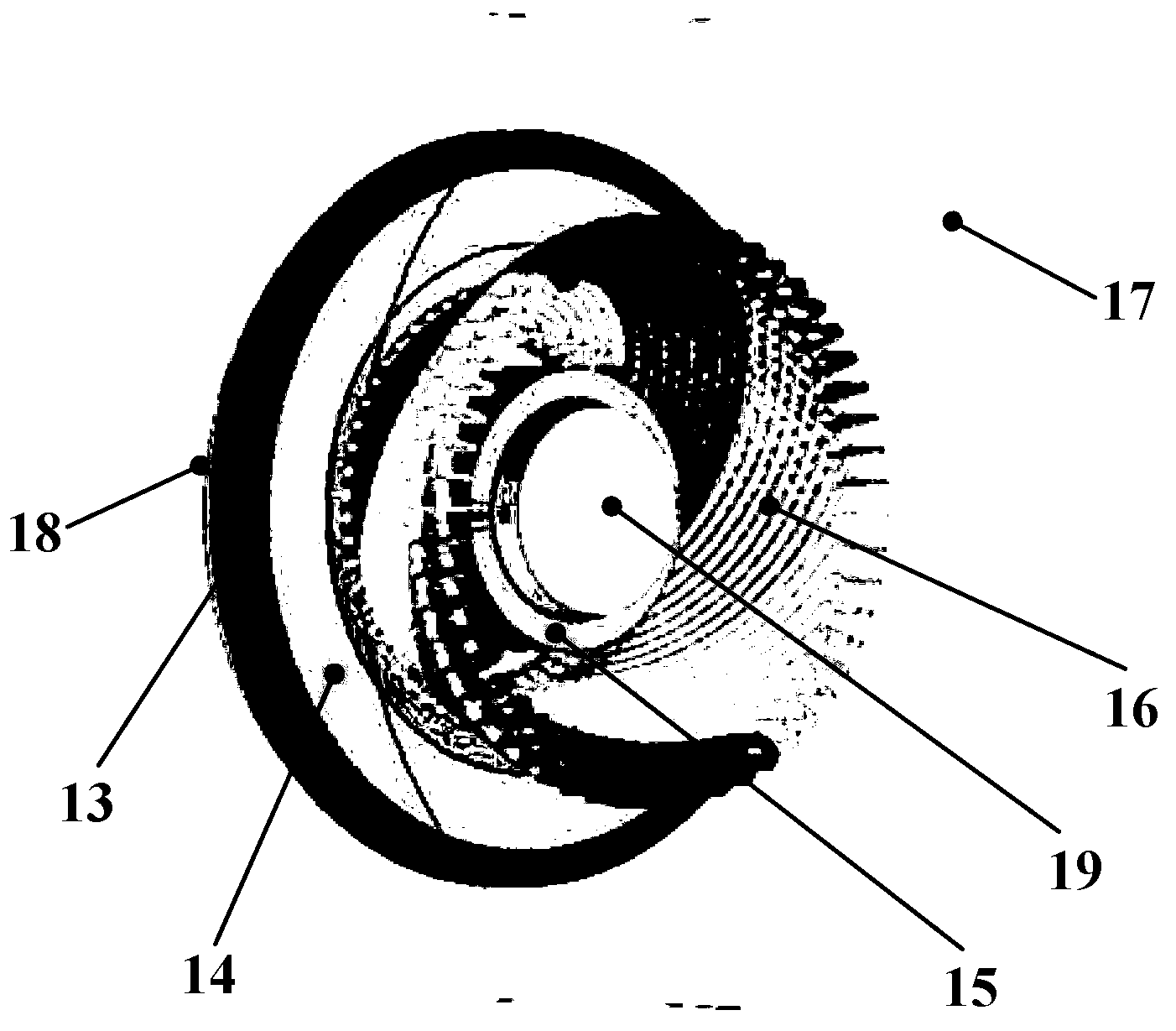

[0069] Step 1: Input the parameterized structure data, parameterized boundary condition data and parameterized grid division data of the synchronous generator into the pre-processing module, and after processing by the pre-processing module, respectively generate a two-dimensional fluid system simulation model, a three-dimensional The end electromagnetic field calculation model and the three-dimensional end fluid and heat transfer coupling calculation model; at the same time, assign the drag coefficient and wind area of each branch of the motor in the two-dimensional fluid system simulation model; apply initialization conditions to the three-dimensional end electromagnetic field ca...

specific Embodiment approach 2

[0073] Embodiment 2: This embodiment further describes Embodiment 1. The parameterized structure data described in this embodiment is the structural size of the synchronous generator.

specific Embodiment approach 3

[0074] Embodiment 3: This embodiment further explains Embodiment 1 or 2. The parameterized boundary condition data described in this embodiment is the actual parameter data and the material properties of the structural parts during the operation of the synchronous generator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com