Drive control unit, drive circuit and drive control method of display substrate

A display substrate and display driver technology, which is applied to static indicators, instruments, etc., can solve the problems of different charging effects of pixels, the influence of image consistency, and large signal line impedance, and achieve the effect of ensuring the consistency of charging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

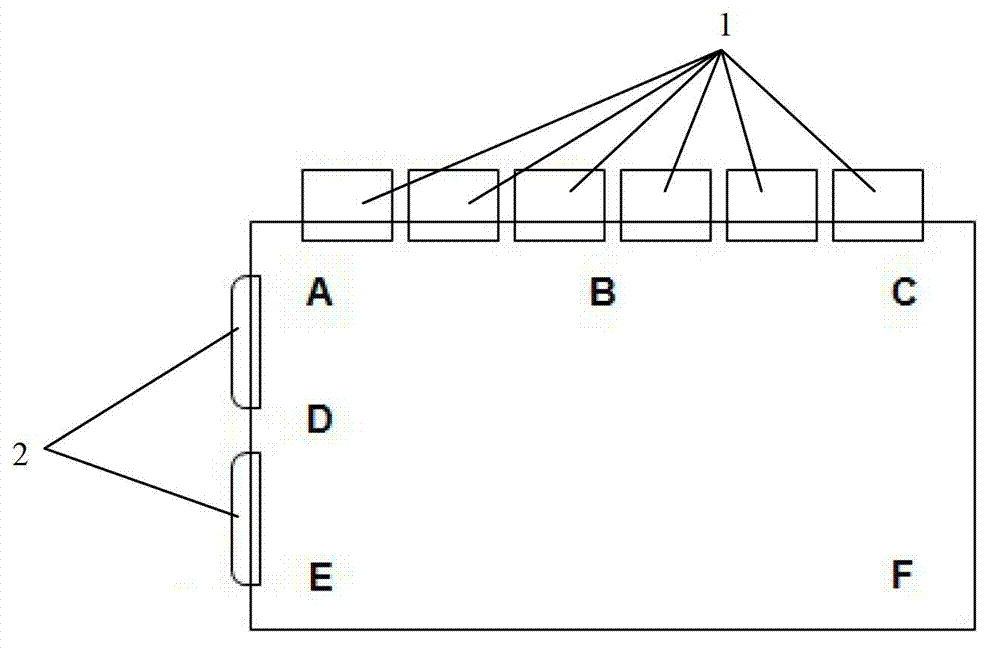

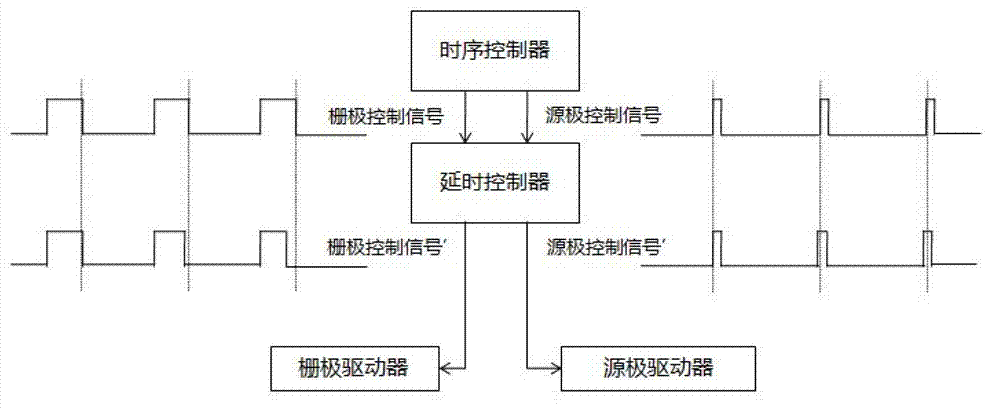

[0054] Such as figure 1 As shown, if the scanning order of the gate lines and data lines on the LCD panel is from left to right and from top to bottom, the pixel point F in the last row and the last column on the LCD panel is the same as the pixel point F in the first row and the first row on the LCD panel. The charging time difference of pixel point A in one column is the largest, therefore, preferably, the delay controller adjusts based on the timing control signal of the pixel point F farthest from the source driver and the gate driver on the liquid crystal panel, The preferred adjustment method is as follows:

[0055] According to the difference between the impedance of the driving signal line connected between the second pixel point on the display substrate and the pixel display driver and the impedance of the driving signal line connected between the first pixel point and the pixel display driver The value is adjusted according to the difference between the impedance of...

Embodiment 2

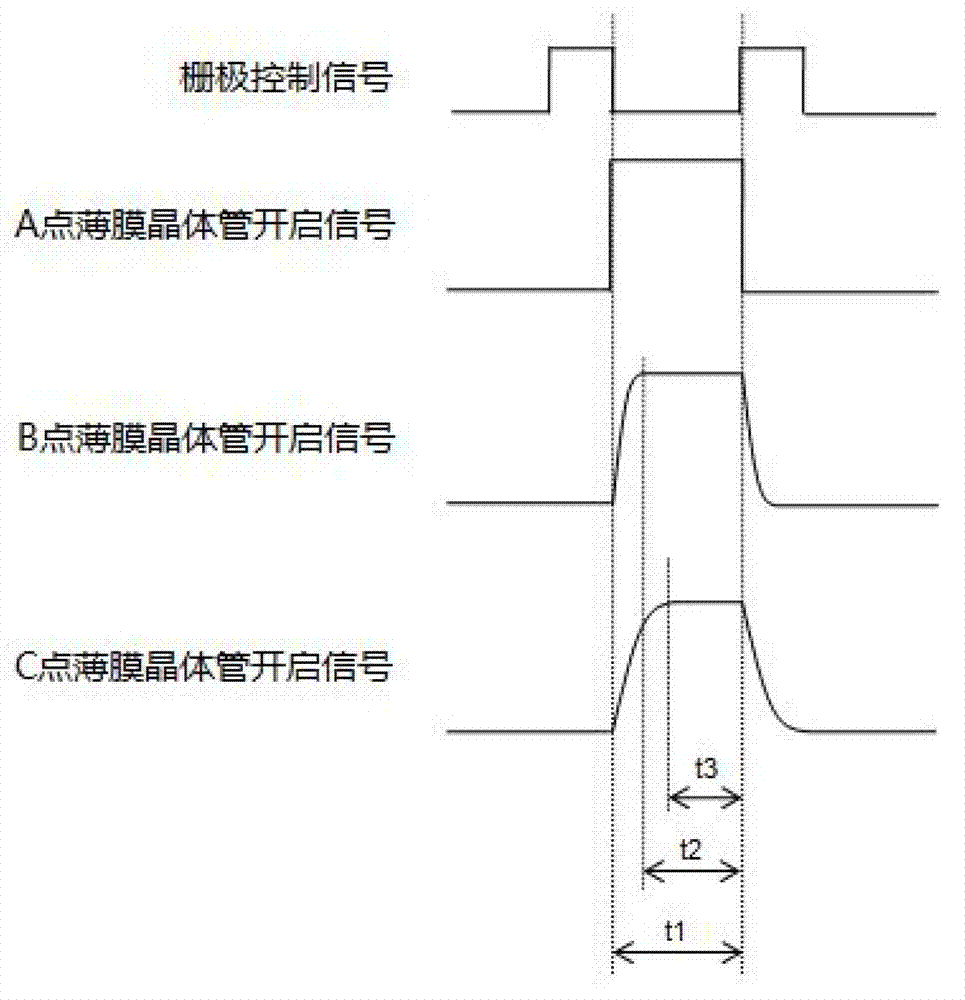

[0060] Such as figure 1 As shown, the charging time difference between the pixel point F in the last row and the last column on the LCD panel and the pixel point A in the first row and the first column on the LCD panel is the largest, and the delay controller is based on the distance between the source driver and the gate on the LCD panel. The timing control signal of the farthest pixel point F of the pole driver is used as a reference, and the delay of the timing control signal of the pixel point in the same column as the pixel point F is adjusted according to the impedance difference between the pixel point F and the pixels in the same column Time, the impedance difference between pixel point C and pixel far point F is the largest, it is necessary to adjust the delay time of the timing control signal of the row where pixel point C is located, so that the timing control signal of the row where pixel point C is located is later than that of the row where pixel point F is locate...

Embodiment 3

[0062] The delay controller adjusts the timing control signal based on the timing control signal of the pixel point C on the same row of the liquid crystal panel farthest from the gate driver, and according to the impedance difference between the pixel point C and the pixel point A and B of the same row The value adjusts the delay time of the timing control signal of the pixel point in the same row as the pixel point farthest from the gate driver in each row. The difference in impedance between pixel point A and pixel point C is the largest, and the timing of the column where pixel point A is located needs to be adjusted. The delay time of the control signal makes the output of the timing control signal of the column where the pixel point A is located later than the timing control signal of the column where the pixel point C is located, so as to compensate for the fact that the control signal of the gate driver between the pixel points A and C is on the glass substrate trace De...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com