Pixel element structure and non-refrigeration infrared focal plane detector based on pixel element structure

A pixel structure and pixel technology, applied in the field of infrared detection, can solve the problems of high equipment cost, long development cycle, complex device manufacturing process, etc., and achieve the effects of easy high-speed response, simplified process difficulty, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

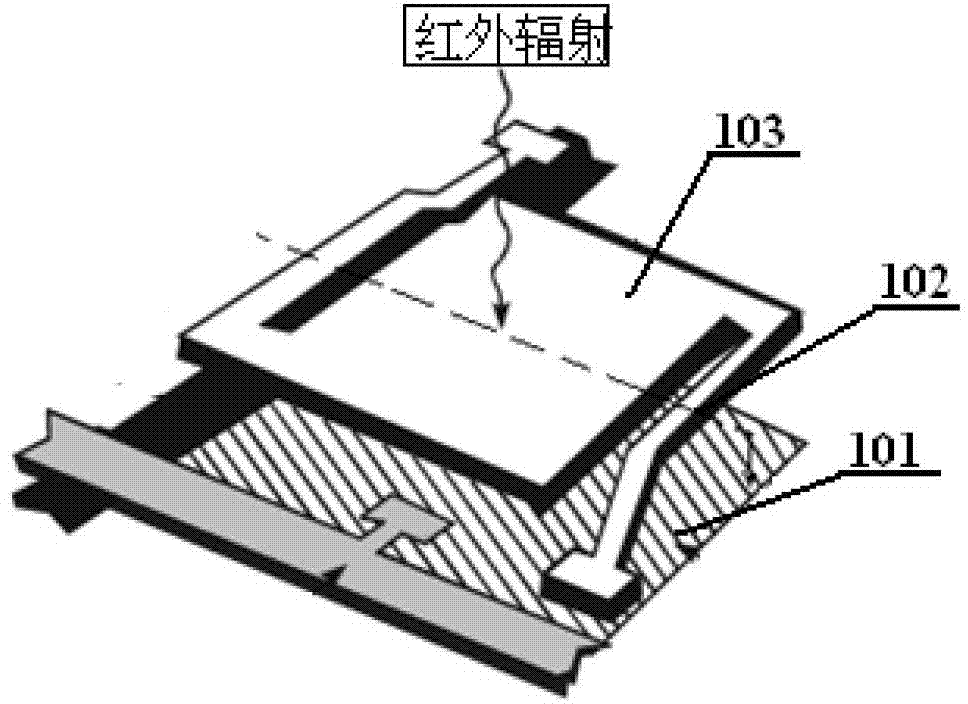

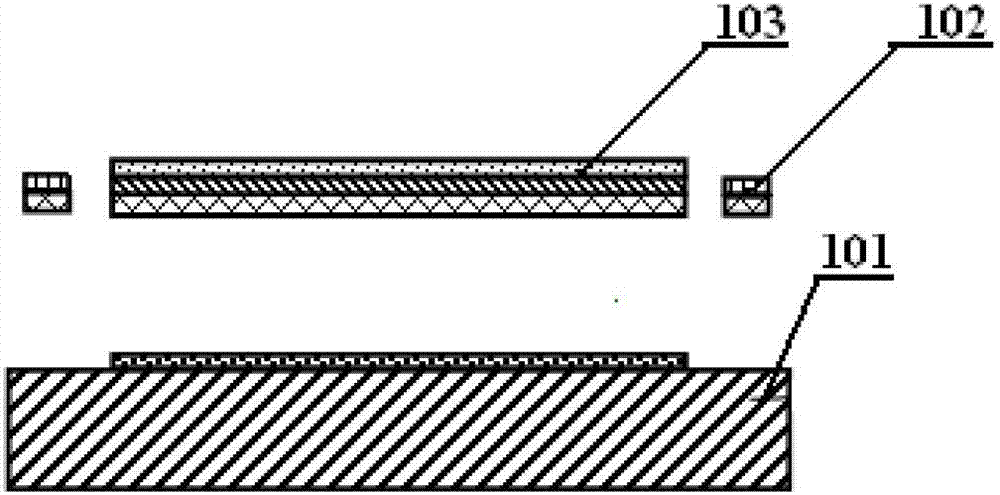

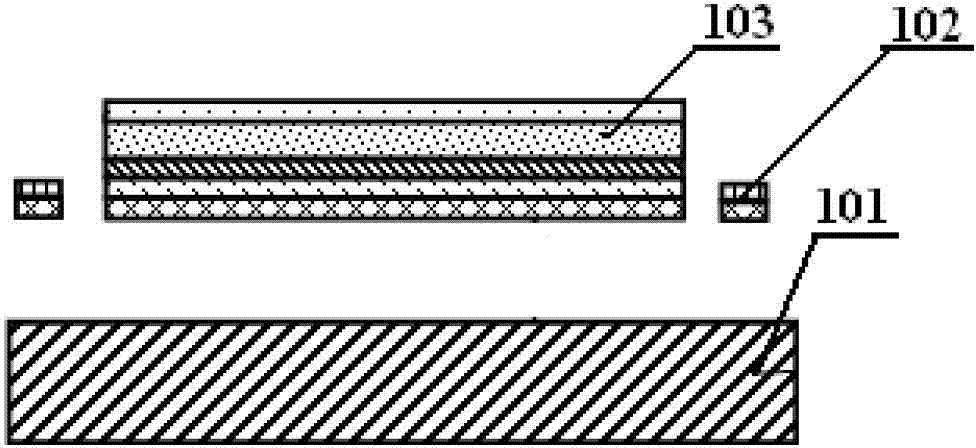

[0037] see Figure 1-8 A pixel structure provided by Embodiment 1 of the present invention includes: a silicon substrate 101, an absorbing unit for absorbing light beams, a conductive unit for connecting the silicon substrate 101 and the absorbing unit, and a conductive unit for converging the radiation beam into the light concentrating unit of the silicon substrate 101. Wherein, a light-transmitting area is provided at the center of the upper surface of the silicon substrate 101, and a readout circuit 110 is provided on the same surface near the periphery of the light-transmitting area; one end of the conductive unit is electrically connected to the absorbing unit, and the other end is connected to the readout circuit 110. The contact electrodes are electrically connected. The absorbing unit is suspended on the upper surface of the silicon substrate 101 through the conductive unit, and the light concentrating unit 104 is fixed on the lower surface of the silicon substrate 10...

Embodiment 2

[0056] see Figure 9-10, Embodiment 2 of the present invention provides an uncooled infrared focal plane detector based on the above pixel structure, including: a first substrate 201 (active board) and a second substrate 202 (passive board). Wherein, one side of the first substrate 201 is provided with at least one light-transmitting area, and the same surface is provided with a readout circuit 110 near the periphery of the light-transmitting area, and the other side is provided with a light-collecting unit 104, and the light-transmitting area is on one side of the first substrate 201 Distributed in an array, the distribution shape of the concentrating units 104 on the other side of the first substrate 201 is adapted to the shape of the pixels in the light-transmitting area; that is, the first substrate 201 is provided with a densely arranged "pixel structure" array, each The central part of the "pixel structure" is provided with a light-transmitting area on one side of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com