Curtain wall structure

A curtain wall and glass technology, applied to walls, building components, building structures, etc., can solve problems such as increased air-conditioning load and indoor temperature rise, and achieve the effects of reducing heat load, improving the environment, and suppressing the reduction of light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

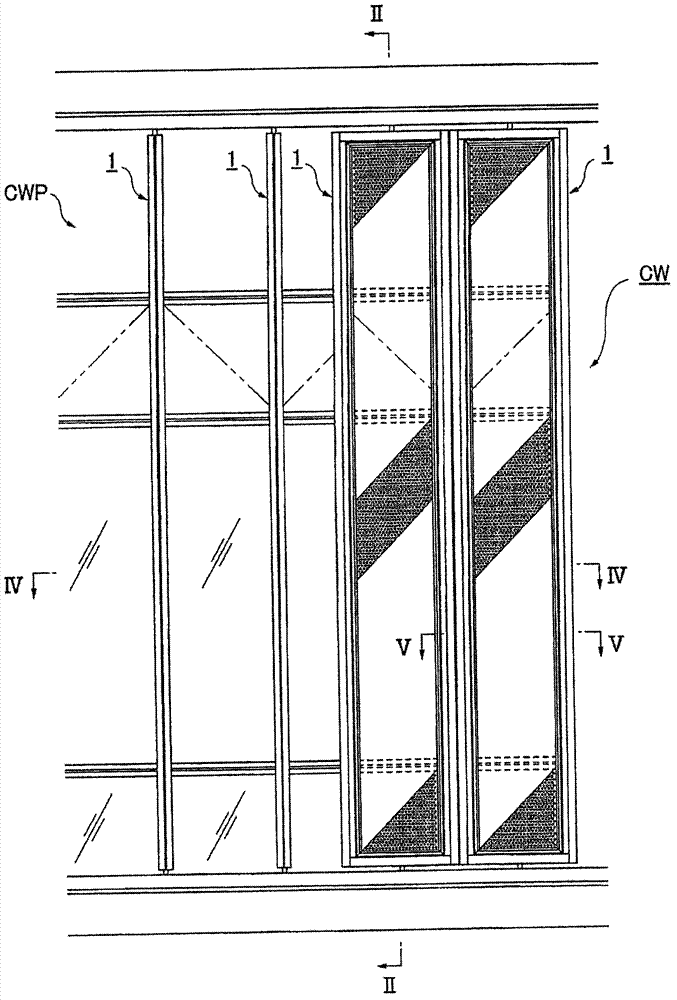

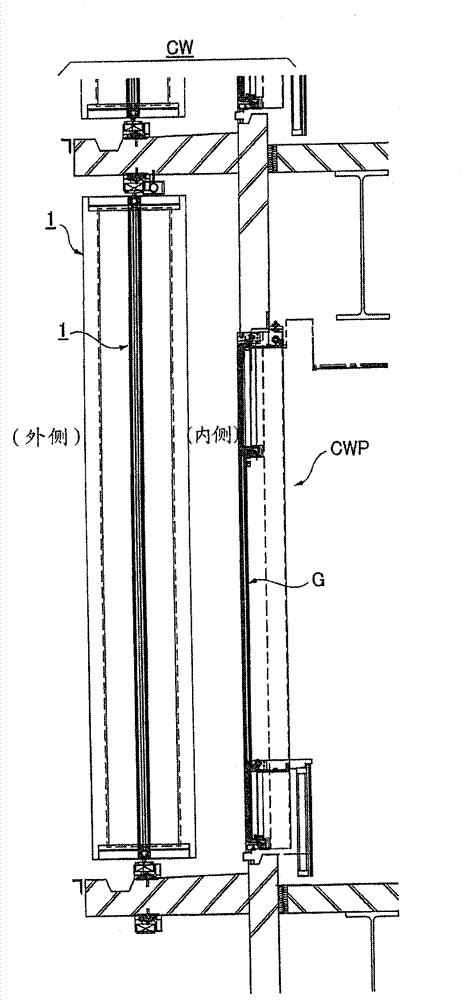

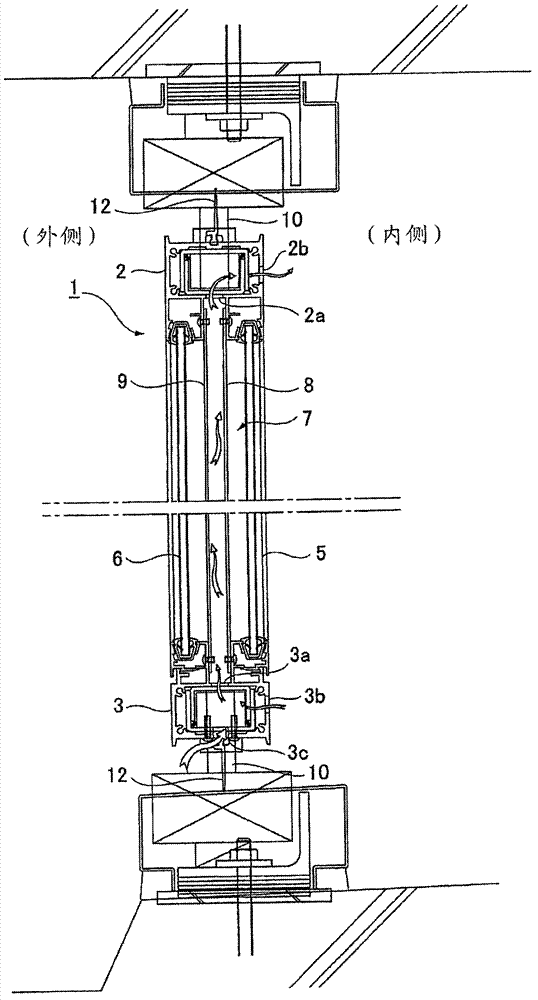

[0054] (Structure of shutter assembly 1)

[0055] In detail, as image 3 and Figure 5 As shown, the shutter assembly 1 of the first embodiment is surrounded by an upper frame 2, a lower frame 3, and left and right vertical frames 4, 4 in a frame, and two pieces of glass 5, 6 are fitted and supported parallel to the frame surface. An air layer 7 is set between the two glasses, and, in the above-mentioned air layer 7, on the above-mentioned frames 2, 3, 4, spaced apart by fixing screws, for example Two perforated panels 8,9.

[0056] Such as image 3 As shown, the above-mentioned upper frame 2 and the lower frame 3 are respectively set as hollow sections, and are formed with air communication ports 2a, 3a communicating with the above-mentioned air layer 7 in the hollow sections, and in the above-mentioned two pieces of glass 5, 6 Air communication ports 2b, 3b communicating with the outside of the frame are formed on the surface of a glass 5 side. In addition, the lower fr...

no. 2 example

[0075] Such as Figure 7 As shown, in the louver assembly 1 of the second embodiment, two perforated panels 8, 9 are arranged in the above-mentioned air layer 7, and the perforated panel 8 disposed on one side of a glass 5 is colored in white. The perforated panel 9 arranged on one side of the other glass 6 is colored in black.

[0076] Thus, in summer mode, if Figure 7 As shown in (A), each louver assembly 1 is rotated, one glass 5 is arranged facing the outside, and the other glass 6 is arranged facing the inside, and the perforated panel 8 which has been colored in white is arranged outside, and the The perforated panel 9 colored in black is disposed inside.

[0077] Thus, the sunlight incident on the shutter assembly 1 passes through a glass 5 and irradiates to the outer perforated panel 8 to generate radiant heat. Moreover, since the perforated panel 8 is colored in white, it reflects most of the sun's rays. Light. In addition, sunlight passing through the openings o...

no. 3 example

[0081] Such as Figure 8 As shown, the louver assembly 1 of the third embodiment is equipped with a perforated panel 8 in the air layer 7. For the perforated panel 8, the surface 8A on the side of the first glass 5 is colored in white, and the other panel is colored white. The surface 8B on the side of the glass 6 is colored in black. In addition, the above-mentioned perforated panel 8 may be formed by bonding and laminating a white-based panel and a black-based panel.

[0082] Also, in summer mode, if Figure 8 As shown in (A), each shutter assembly 1 is rotated, one glass 5 is arranged facing outward, the other glass 6 is arranged facing inward, and the surface 8A of the perforated panel 8 that is colored with white is arranged facing outward, The surface 8B colored in black is arranged facing inward.

[0083] Thus, the sunlight entering the louver assembly 1 passes through the glass 5 and irradiates the perforated panel 8 to generate radiant heat, and since the outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com