Manipulator control system and control method

A control system and manipulator technology, applied in the field of manipulators, can solve problems such as poor precision of the manipulator control system, achieve the effect of improving work efficiency and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

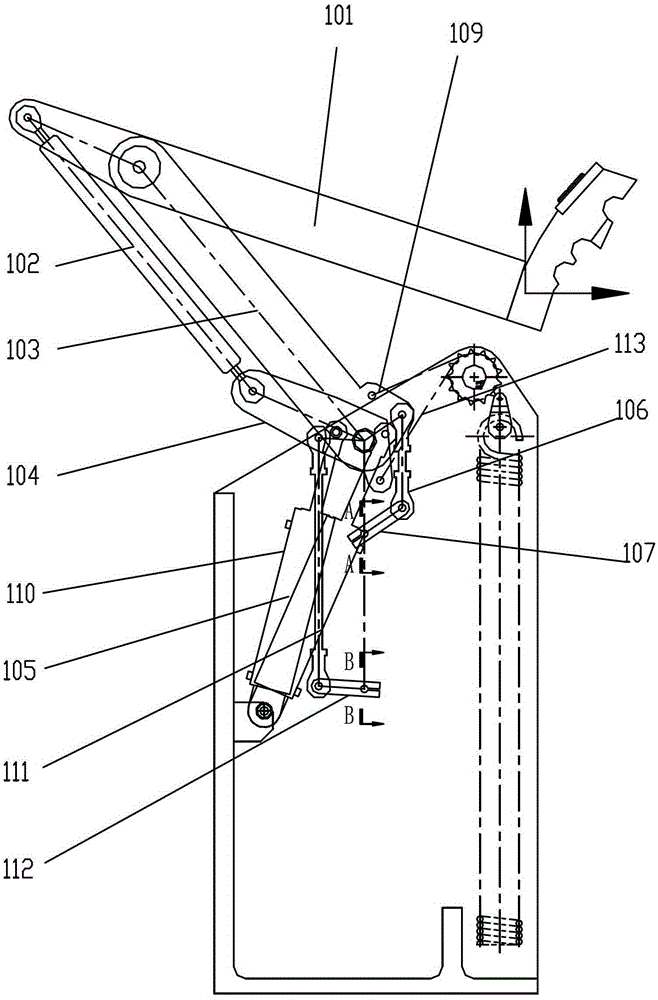

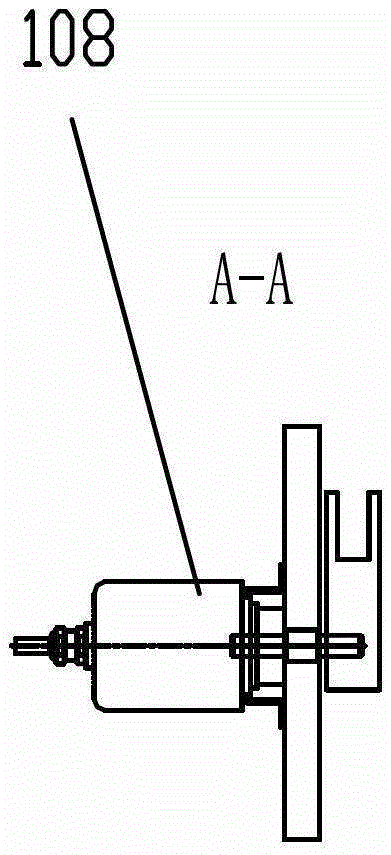

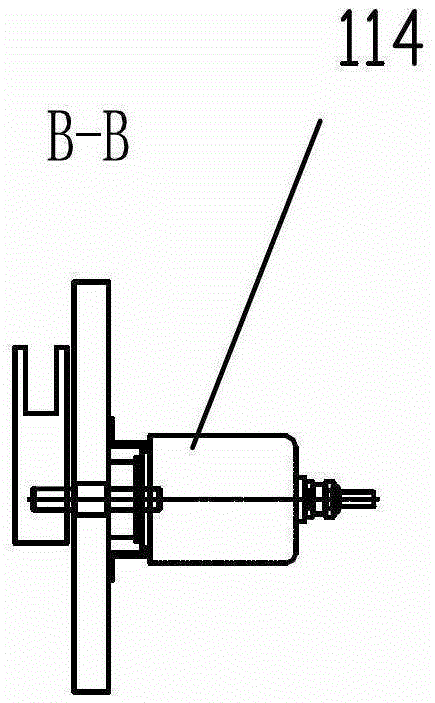

[0035] Such as Figure 1 to Figure 6 As shown, a manipulator control system includes a simulated handle assembly that controls the motion trajectory of the manipulator; a hydraulic conversion device that converts the motion state of the simulated handle assembly into an identifiable electrical signal; a power device that controls the motion of the manipulator; receives the electrical signal, and An information processing device that controls the motion of a power unit with signals.

[0036] The simulation handle assembly includes a handle and a connecting rod structure connected to the handle. The connecting rod structure is a parallel four-bar connecting rod structure formed by a telescopic connecting rod 102, a lifting connecting rod 104, a main connecting rod 103 and the arm 101, and the handle is installed on the arm 101.

[0037] The hydraulic conversion device includes an execution device connected to the connecting rod structure and a motion data detection device for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com