A wood rotary cutting machine without card shaft

A technology of wood rotary cutting machine and clamping shaft, which is applied in the direction of wood processing equipment, thin wood chip manufacturing, and tool manufacturing. Effect of surface indentation, reduction of damage, and reduction of extrusion force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

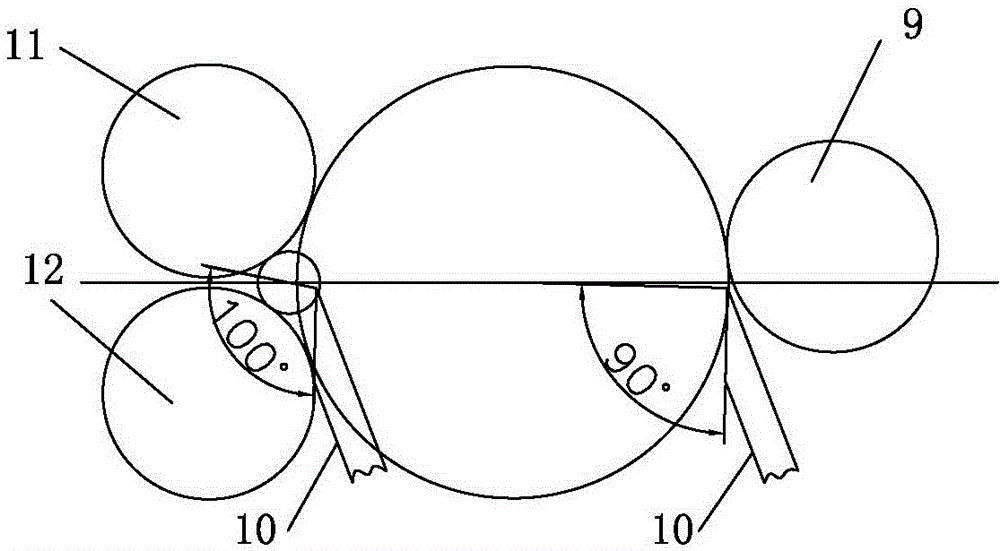

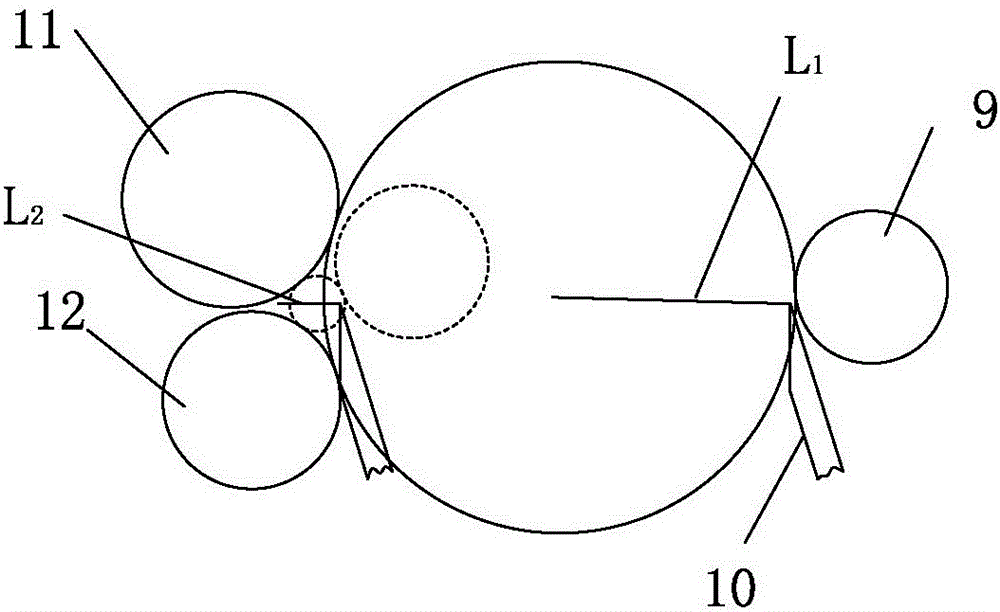

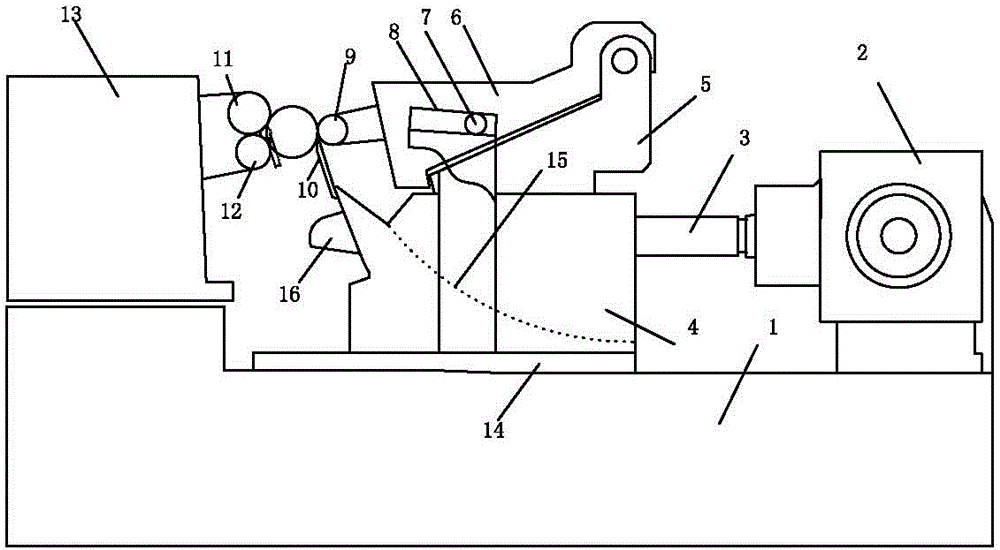

[0038] A wood rotary cutter without card shaft, such as figure 2 , image 3 As shown, it includes a frame 1, a rotary cutting mechanism, and a driving mechanism.

[0039] The rotary cutting mechanism includes a first driving roller 11, a second driving roller 12 and a cloth roller 9 arranged on the frame 1 for rolling wood, the diameter of the first driving roller 11 is greater than the diameter of the second driving roller 12, and the second The diameter of the driving roller 12 is greater than the diameter of the cloth roller 9, the first driving roller 11 and the second driving roller 12 are arranged obliquely up and down, and the connecting line of the first driving roller 11 and the second driving roller 12 is connected to the center of the wood. The included angle of the horizontal line is an obtuse angle, and the roller center point of the cloth plate roller 9 is located above the central horizontal line of the wood;

[0040] The rotary cutting mechanism is also prov...

Embodiment 2

[0052] A kind of shaft-free wood rotary cutter of the present invention, as image 3 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that the roller surfaces of the first driving roller 11 , the second driving roller 12 , and the fabric roller 9 are respectively provided with brushed lines with a depth of 0.2-0.5 mm.

[0053] The surface of the three rollers can be set with 0.2-0.5mm brushed pattern as friction pattern, which can keep the wood rotating normally, prevent the wood from slipping, improve the rotary cutting effect, and will not leave indentation on the veneer after rotary cutting.

Embodiment 3

[0055] A kind of shaft-free wood rotary cutter of the present invention, as image 3 As shown, the main technical solutions of this embodiment are basically the same as those of Embodiment 1, and the features not explained in this embodiment are explained in Embodiment 1, and will not be repeated here. The difference between this embodiment and Embodiment 1 is that a plank conveying mechanism is provided, and the plank conveying mechanism is set as a belt-type plank conveying mechanism, and the plank conveying mechanism is connected with the pallet 15 for outputting the pallet 15 output of planks.

[0056] The wood board conveying mechanism outputs the veneer after rotary cutting along the board rack 15, and then collects it. The collection effect is good, and the veneer rupture caused by folding is avoided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com