An electric drive system for electric wheels

A drive system and electric vehicle technology, applied in the direction of power devices, motion deposition, vehicle components, etc., can solve the problems of exciting the noise inside the vehicle, increasing the unsprung mass, and reducing the ride comfort of the vehicle, so as to reduce the level of vibration and noise, The effect of improving the ride comfort of the vehicle and improving the handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

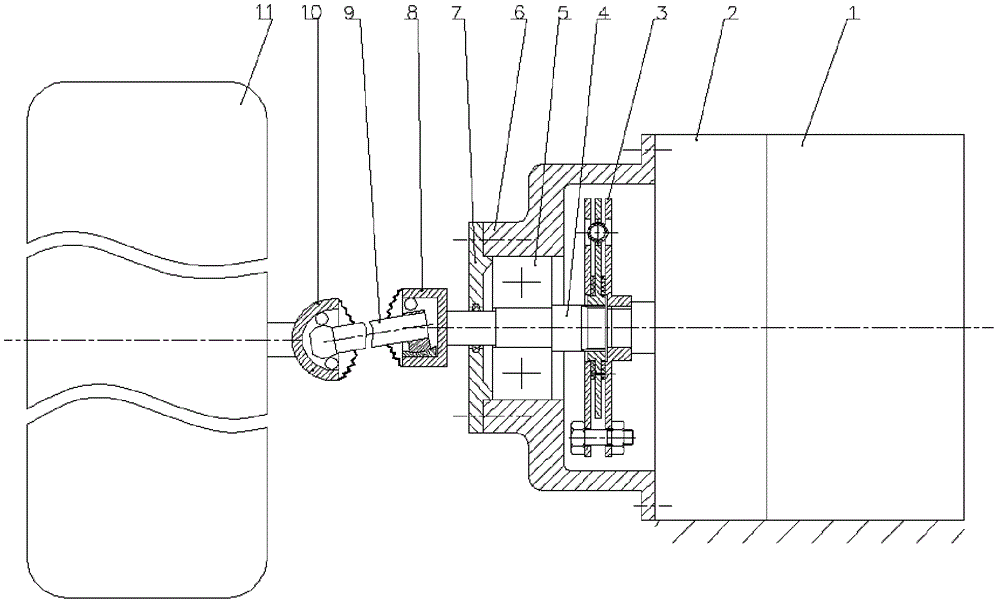

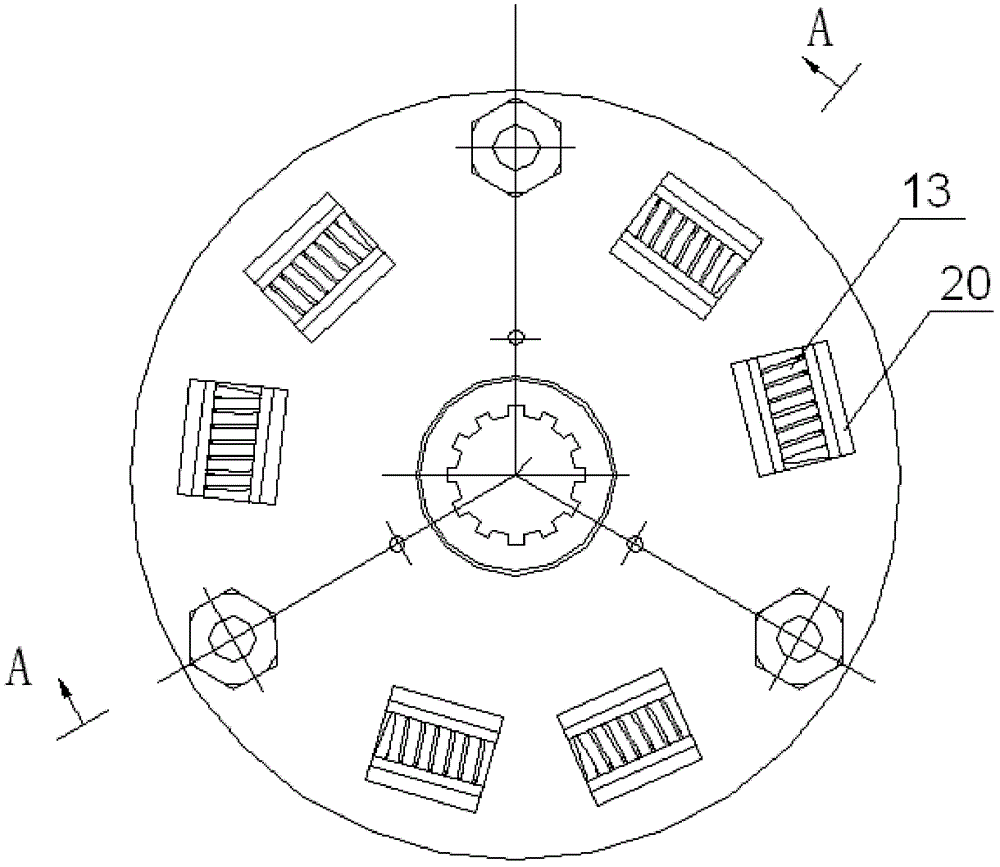

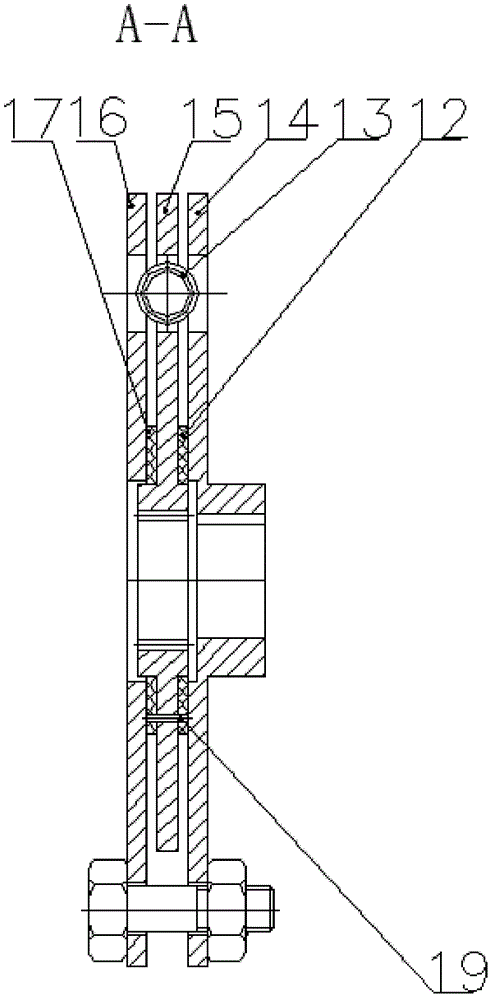

[0027] Such as figure 1 As shown, an electric wheel drive system includes a torsional shock absorber 3, a transmission mechanism, a torsional shock absorber cover 6, a shock absorber dust cover 7, and a motor composed of a motor 1 and a gear reduction mechanism 2. powertrain. The motor power assembly is fixed on the vehicle frame, one end of the torsional shock absorber cover 6 is fixed on the gear reduction mechanism 2, and the other end is provided with a cover opening, and the shock absorber dustproof cover plate 7 is arranged on the cover opening, and is connected with the torsion The shock absorber cover 6 and the gear reduction mechanism 2 form a cavity, and the torsional shock absorber 3 is located in the cavity, and is connected to the gear reduction mechanism 2 through a flat key. The transmission mechanism includes a spline shaft 4, a telescopic cage type constant velocity universal joint 8, a driving half shaft 9, and a fixed cage type constant velocity universal j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com