Continuous-walking type hydraulic pushing device

A hydraulic and jacking technology, applied in the direction of hoisting device, winch device, etc., to achieve the effect of low cost, simple and reasonable structure, and saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

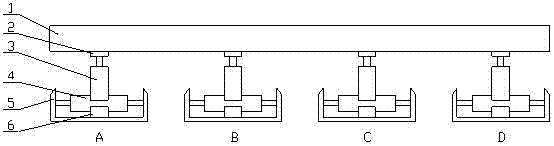

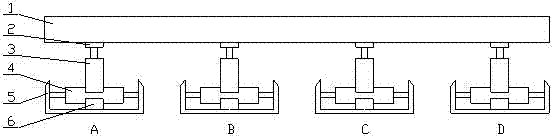

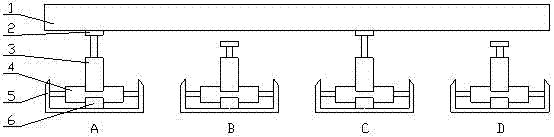

[0023] Embodiment 1: A continuous walking hydraulic jacking device, including a jacking tray 2 , a longitudinal hydraulic jacking cylinder 3 , a horizontal hydraulic jacking cylinder 4 , a cylinder base 5 and a cylinder support seat 6 .

[0024] The push pallet 2 is welded on the piston rod of the longitudinal hydraulic push cylinder 3 . The cylinder body of longitudinal hydraulic jacking cylinder 3 is vertically welded in the cylinder body center of horizontal hydraulic jacking cylinder 4, and can move left and right with the cylinder body of horizontal hydraulic jacking cylinder 4. The cylinder base 5 is welded with the piston rods at both ends of the horizontal hydraulic push cylinder 4 . The horizontal hydraulic jacking cylinder 4 rests on the oil cylinder support base 6 , and the cylinder body of the horizontal hydraulic pressure thrust cylinder 4 can move left and right relative to the oil cylinder support base 6 . Each hydraulic jacking cylinder is controlled by a comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com