Ozone generator of bionic cellular type discharge unit nesting structure

An ozone generator and discharge unit technology, applied in the field of ozone generators, can solve the problems that the output of ozone equipment cannot be adjusted according to actual needs, it is not easy to produce, install and maintain, and the ozone generator is shut down. Reduced maintenance work and labor costs, the effect of reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

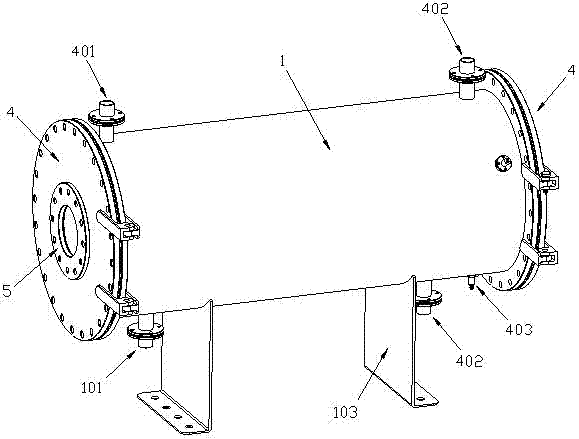

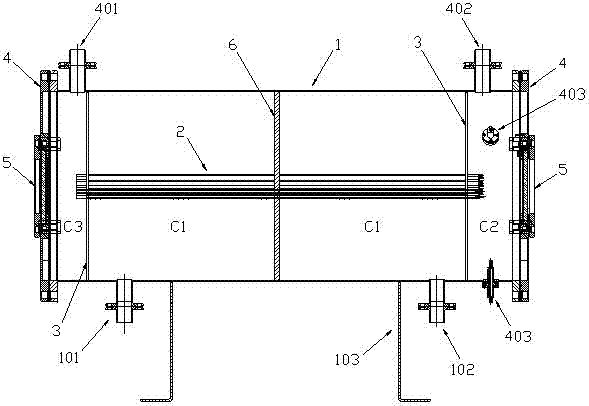

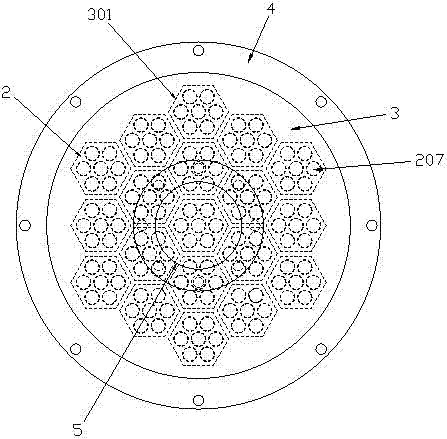

[0018] Embodiment one: if Figure 1~5 As shown, an ozone generator with a nested structure of bionic honeycomb discharge units includes a recumbent cylinder 1, and the two ends of the cylinder 1 are respectively sealed and connected with end caps 4, and the cylinder 1 is vertically provided with Two honeycomb discharge module fixed disks 3, the cavity between the two cellular discharge module fixed disks 3 forms a discharge chamber C1, and the cavity between the two honeycomb discharge module fixed disks 3 and the end cap 4 at the corresponding end is respectively Oxygen chamber C2 and ozone chamber C3 are formed, and at least one honeycomb discharge module 2 with several honeycomb discharge units 201 is arranged in the discharge chamber C1, and the two ends of the honeycomb discharge unit 201 are respectively sealed and nested On the two regular hexagonal honeycomb discharge unit fixing plates 202, the two ends of the honeycomb discharge module 2 are sealed and nested in the ...

Embodiment 2

[0026]Embodiment 2: An ozone generator with a nested structure of bionic honeycomb discharge units, including a recumbent cylinder 1, the two ends of the cylinder 1 are respectively sealed and connected with end caps 4, and the cylinder 1 is vertically installed There are two highest-level honeycomb discharge module fixing plates 3, and a discharge chamber C1 is formed between the two highest-level honeycomb discharge module fixing plates 3, and between the two highest-level honeycomb discharge module fixing plates 3 and the end cap 4 at the corresponding end An oxygen chamber C2 and an ozone chamber C3 are respectively formed. The discharge chamber C1 is provided with a multi-level honeycomb discharge module 2 as described above, and the two ends of each higher-level honeycomb discharge module are sealed and nested in two A corresponding level honeycomb discharge module fixing plate 3, each higher level honeycomb discharge module contains several lower level honeycomb discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com