Device for performing fast and effective separation and purification on turbid circulating water of steel rolling

A turbid ring water, fast technology, applied in the direction of metallurgical wastewater treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc. Frequent replacement of scale water nozzles, guides and cooling water drains of the rolling mill, iron oxide particles and white pollutants blocking the waterway, etc., to achieve the effect of reducing maintenance workload, good effect, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

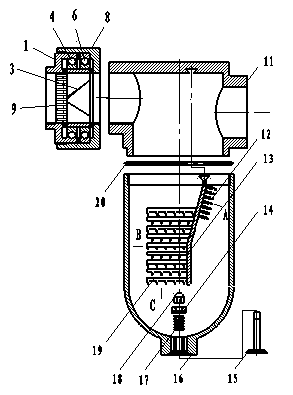

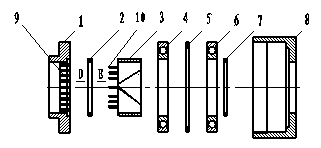

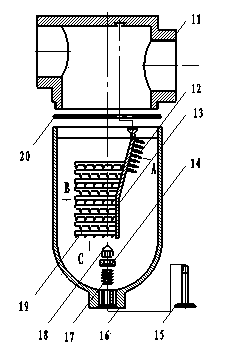

[0021] The present invention includes two parts: a turbofan crusher and a separation shredder. The turbofan crusher and the separation shredder are self-contained and can be used alone or in combination. When used in combination, the turbofan crusher is connected to the separation shredder Crusher export.

[0022] The turbofan breaker consists of an end cover 1, a water seal 2, a turbofan rotor 3, a bearing 4, a spacer 5, a bearing 6, a water seal 7, and a stator 8.

[0023] As shown in the figure, the stator 8 is a cylinder with an end face, and there are screw holes on the end face. The water descaling, guide and guard are connected to the inlet water pipe of the mill water drain, and can also be connected to the water outlet of the separation shredder.

[0024] The figure shows that the inner wall of the stator 8 cylinder has internal threads, and the outer circumference of the end cover 1 has external threads. The external threads of the end cover 1 match the internal thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com