Masterbatch, Rubber Composition, And Pneumatic Tire

A technology of rubber composition and masterbatch, applied in special tires, tire parts, tire tread/tread pattern, etc., can solve the problems of dissatisfaction, reinforcement and cost advantages, etc., and achieve the effect of improving rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] The present invention will be specifically described below with reference to examples, but the present invention is not limited to these examples.

[0092] The chemicals used in the examples are shown below.

[0093] Natural rubber latex: fresh latex, purchased from Muhibbah LATEKS Sdn Bhd (Sdn. Bhd.).

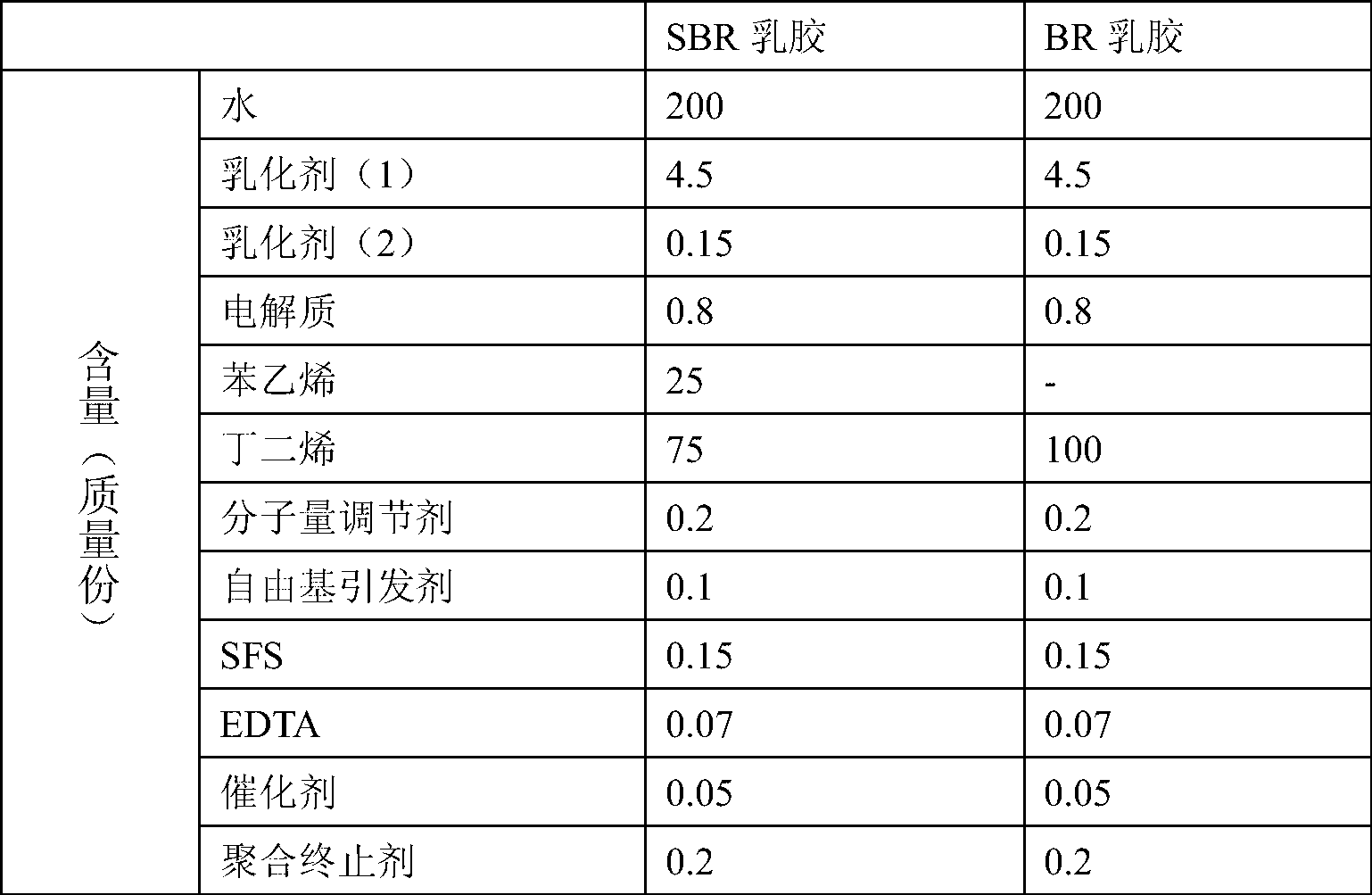

[0094] BR Latex: Prepared by the following method.

[0095] SBR Latex: Prepared by the following method.

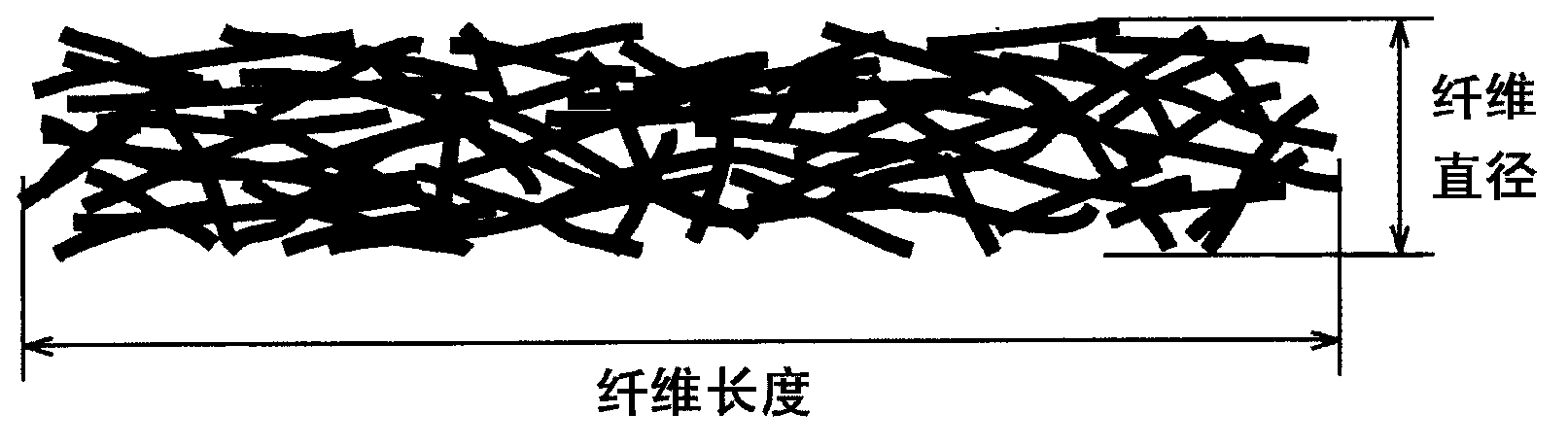

[0096] Microfibrillated plant fiber: NEOFIBER (manufactured by OJI SEITAI KAISHA CORPORATION).

[0097] Surfactant: Emal-E (sodium polyoxyethylene lauryl ether sulfate) (manufactured by Kao Corporation).

[0098] NaOH: NaOH (manufactured by Wako Pure Chemical Industries, Ltd.).

[0099] Coagulant: POIZ C-60H (methacrylate polymer) (manufactured by Kao Corporation).

[0100] Coagulant: 1% sulfuric acid (manufactured by Wako Pure Chemical Industries, Ltd.

[0101] NR:TSR20

[0102] IR: IR2200

[0103] BR 1: BR150B (manufactured by Ube Industries, Ltd.).

[0...

PUM

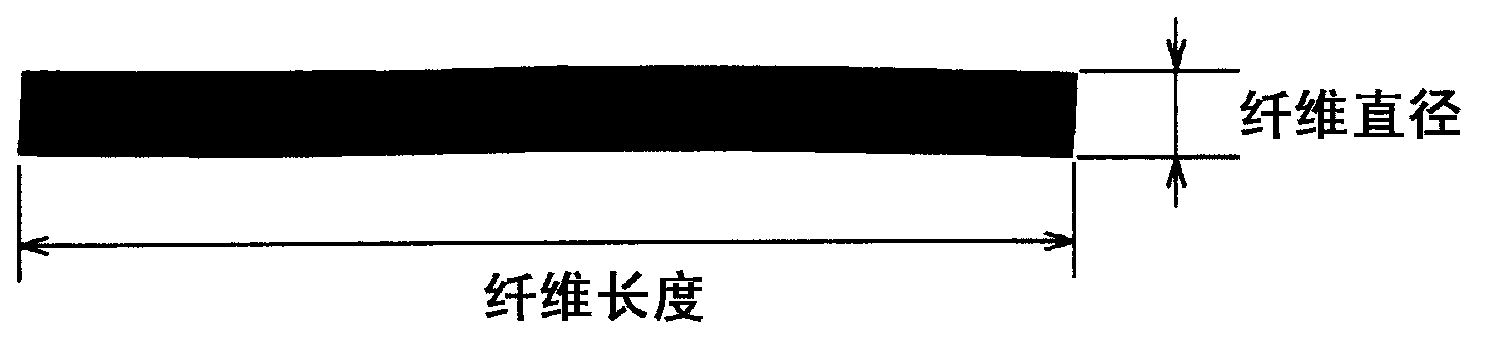

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com