Automatic cleaning and maintaining machine of highway guardrail

A highway guardrail, fully automatic technology, applied in the direction of road surface cleaning, cleaning methods, construction, etc., can solve the problems of complex structure, difficulty, inconvenient maintenance, etc., and achieve the effect of multiple functions and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

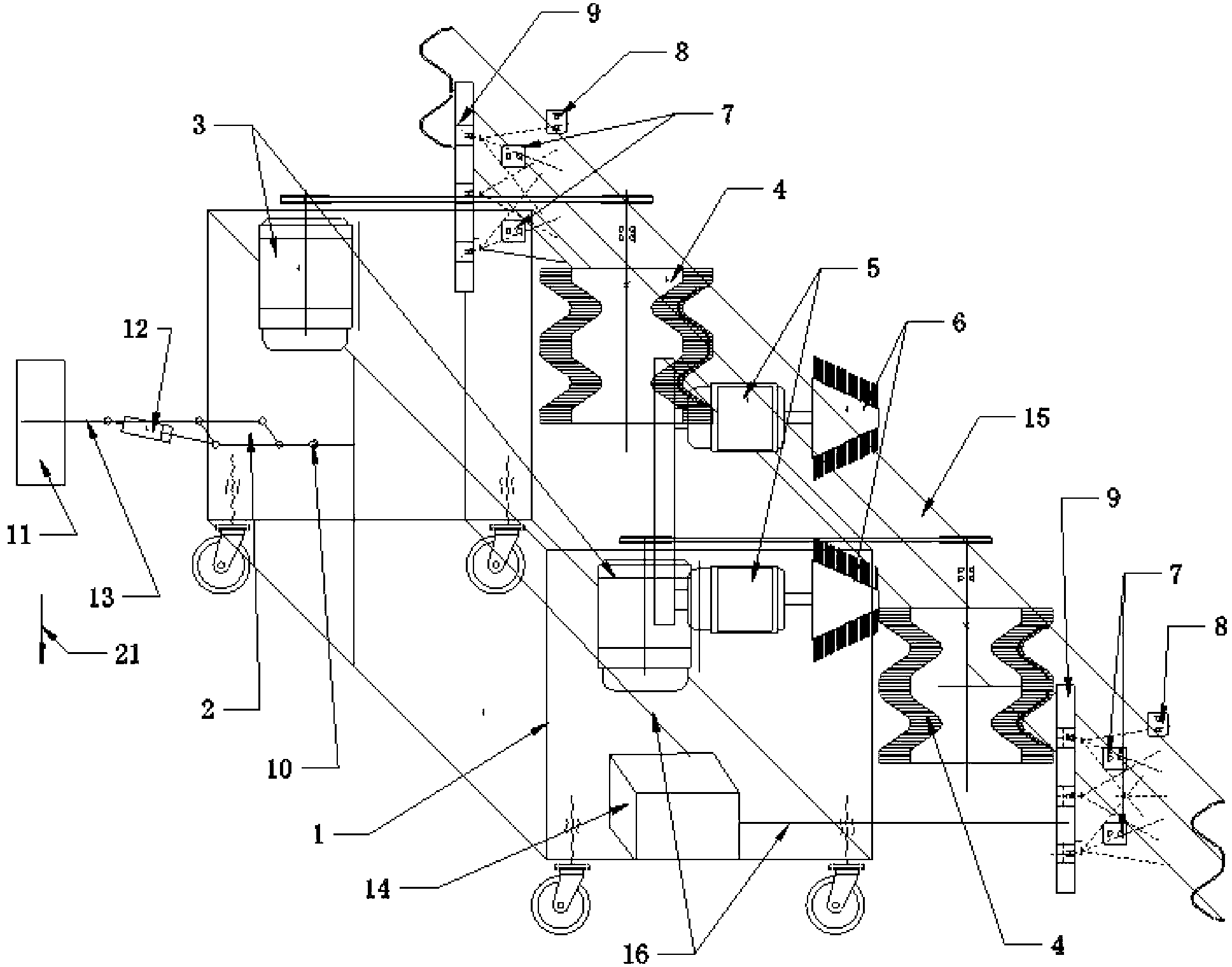

[0019] Example as Figure 1-3 As shown, this example is a washing-type automatic cleaning and maintenance machine for road guardrails, which includes a carrying vehicle 1 that is located on one side of the traveling drive device (driving vehicle) 11 and can roll on the road surface; the carrying vehicle 1 passes through a ball hinge 10 Connected with the four-bar linkage mechanism 2, the four-bar linkage mechanism 2 is fixedly connected with the travel drive device (vehicle) 11 through a driving connecting rod 13; Formula piston cylinder 12. The function of the piston cylinder 12 is to switch between the working and non-working states of the curing machine, and to maintain a corresponding state when the curing machine is working.

[0020] The two horizontal (horizontal) tapered roller brushes 6 whose axial surface shape is tapered correspond to the upper side wall (top side) and lower side wall (bottom side) of the guardrail 15, respectively, through the corresponding tapered...

Embodiment 2

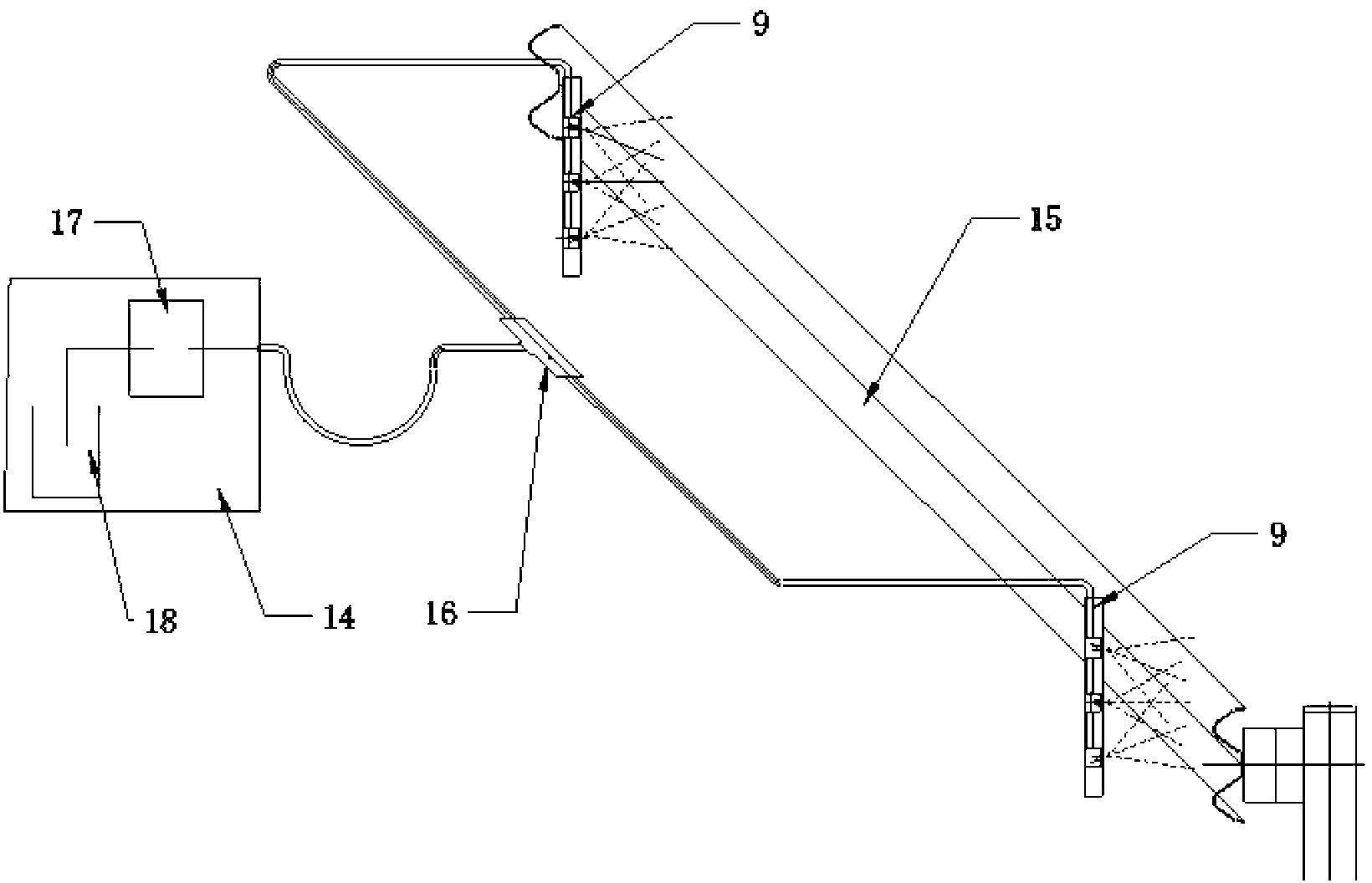

[0027] Example 2 as Figure 4 As shown, the cleaning agent processing device 14 includes a material container 18, and a booster pump 19 and the like; the booster pump 19 carries out pressurized atomization of the cleaning agent in the material container 18, and then is sent to each nozzle through the pipeline 16 to soften the cleaning agent. And remove all kinds of dirt attached to the surface of the barrier. Other structures and the like can be similar to the above-mentioned embodiments.

Embodiment 3

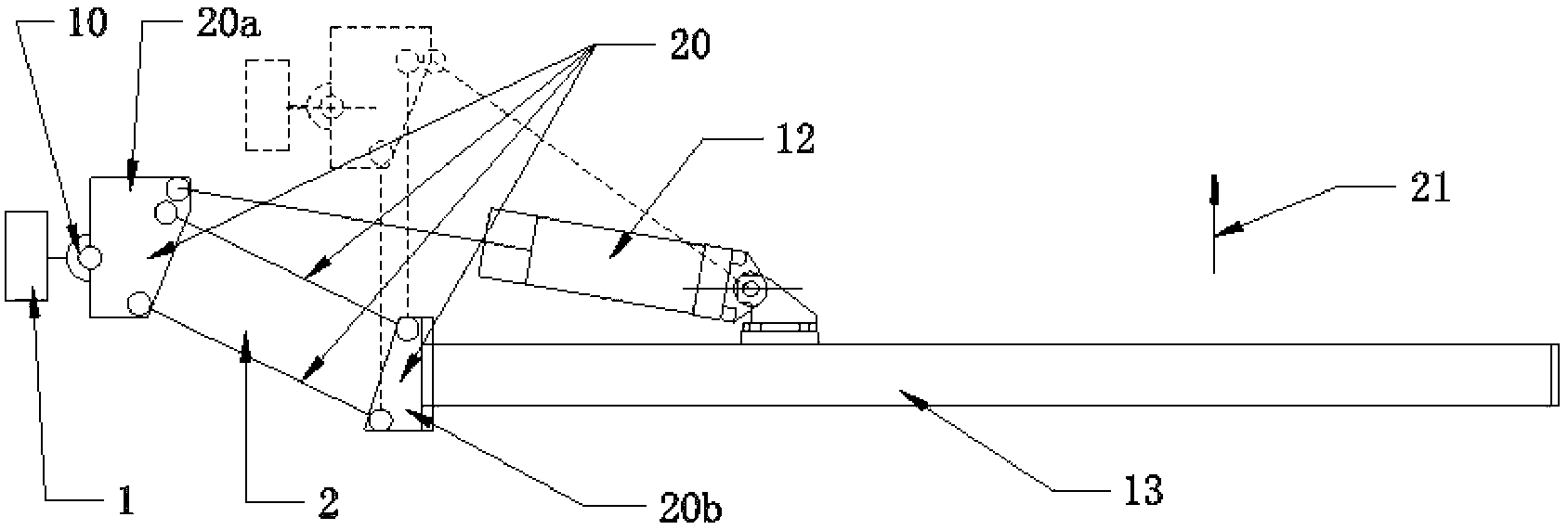

[0028] Embodiment three such as Figure 5 and 6 as shown,

[0029] This embodiment is a spray protection type automatic cleaning and maintenance machine for road guardrails. Its body is a cantilever frame 1a suspended from the road surface. The cantilever frame 1a is suspended in the air through a vertical column hinge 10a through a four-bar linkage mechanism 2. It is connected to the driving connecting rod 13 of the traveling driving device 11 on the ground. The four-bar linkage mechanism 2 is a translational four-bar linkage mechanism that moves (telescopically or swings) forward, backward, left and / or right in the plane direction.

[0030] The cantilever frame 1a is connected with the vertical guide positioning roller 7 that is attached to the corresponding surface wall surface of the guardrail 15. Compared with the first embodiment, there is no transverse guide positioning roller, and the cantilever frame 1a corresponds to the guardrail 15 in a front and back respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com