Device for realizing LED (Light Emitting Diode) encapsulation

A technology of LED packaging and LED chips, which is applied in the field of LED light sources, can solve the problems of unfavorable promotion and use of LED lamps, increased production cost of LED lamps, high production cost and high use cost, and achieves shortened heat conduction path, good heat dissipation effect, and convenient batch production The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

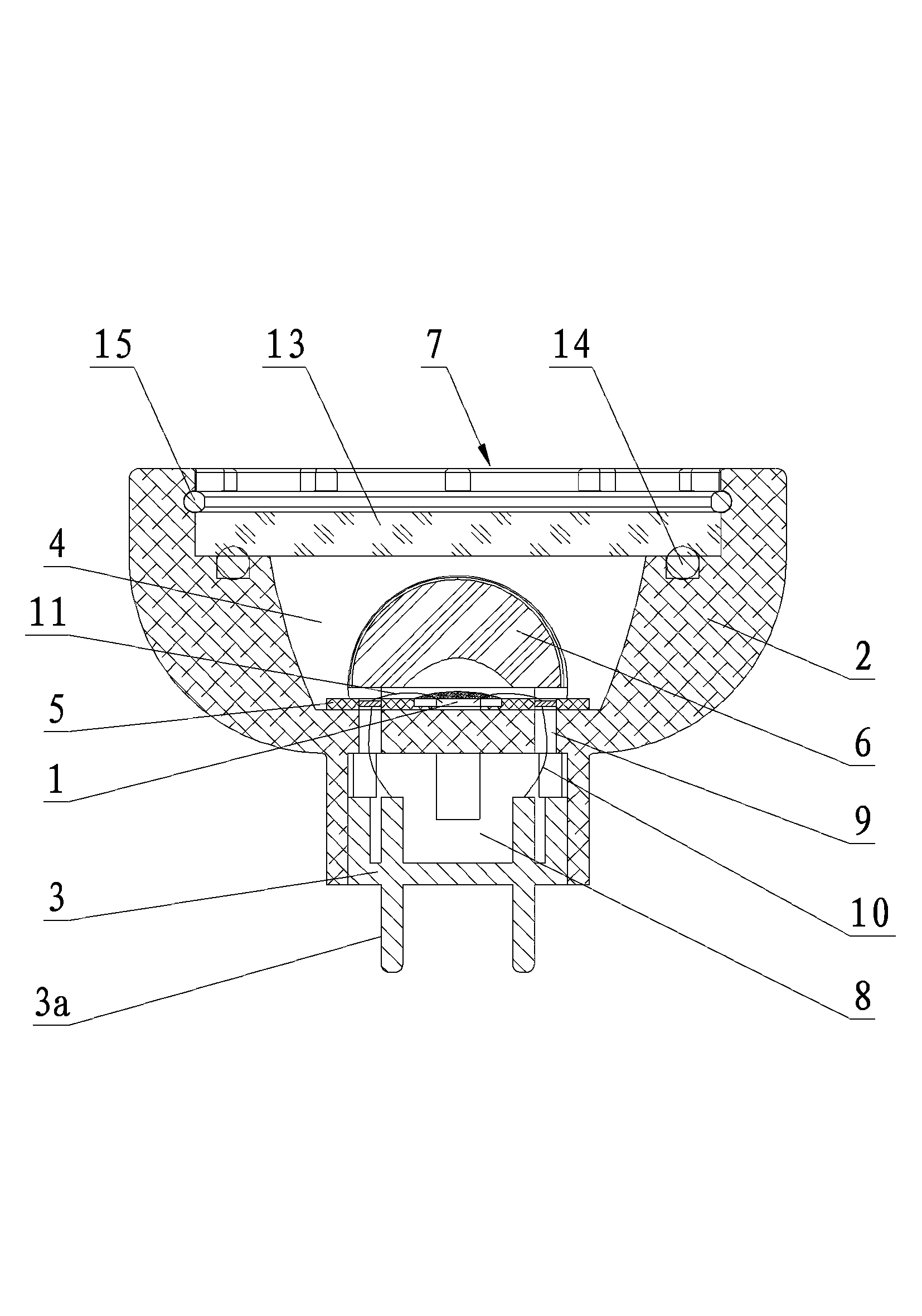

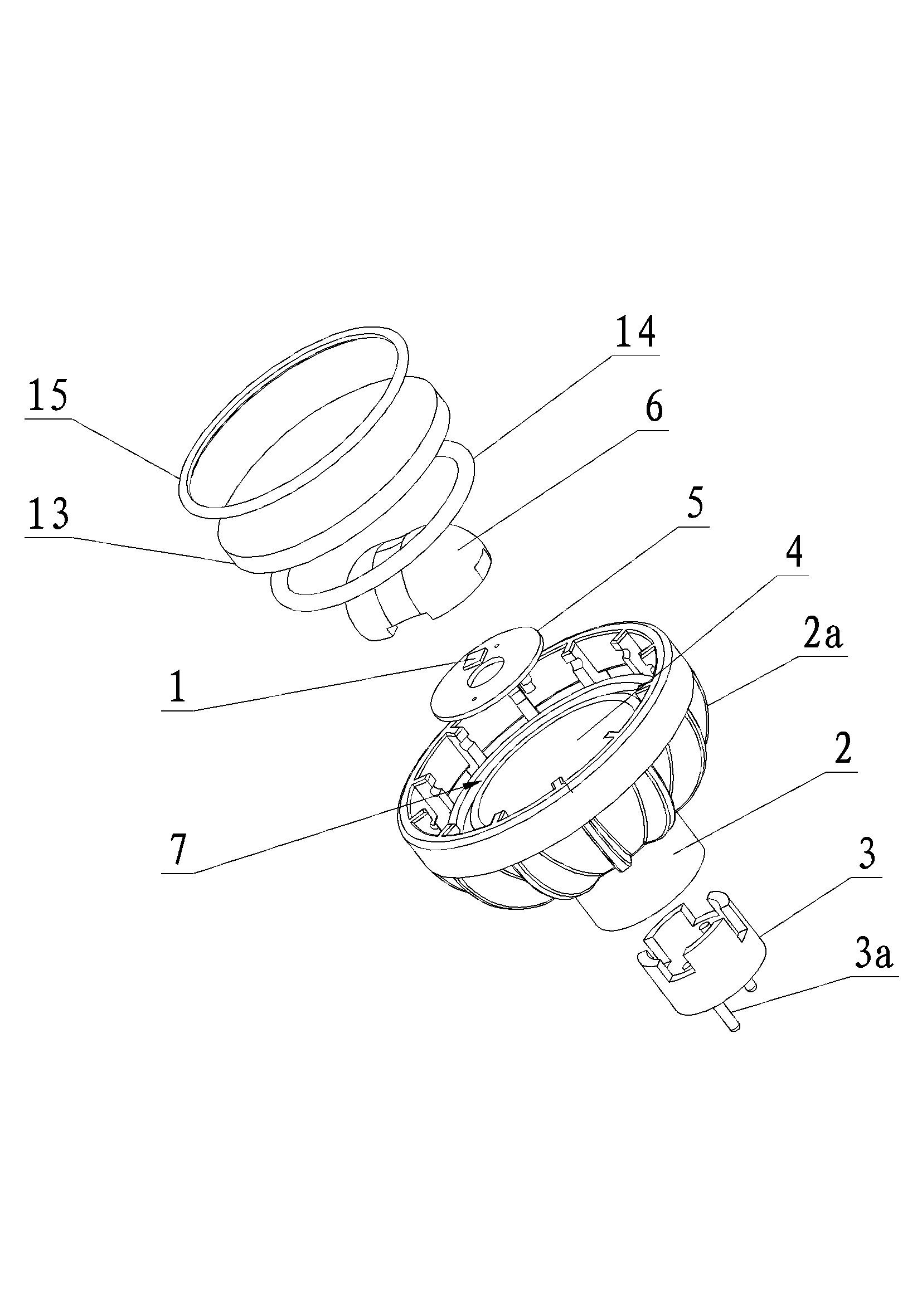

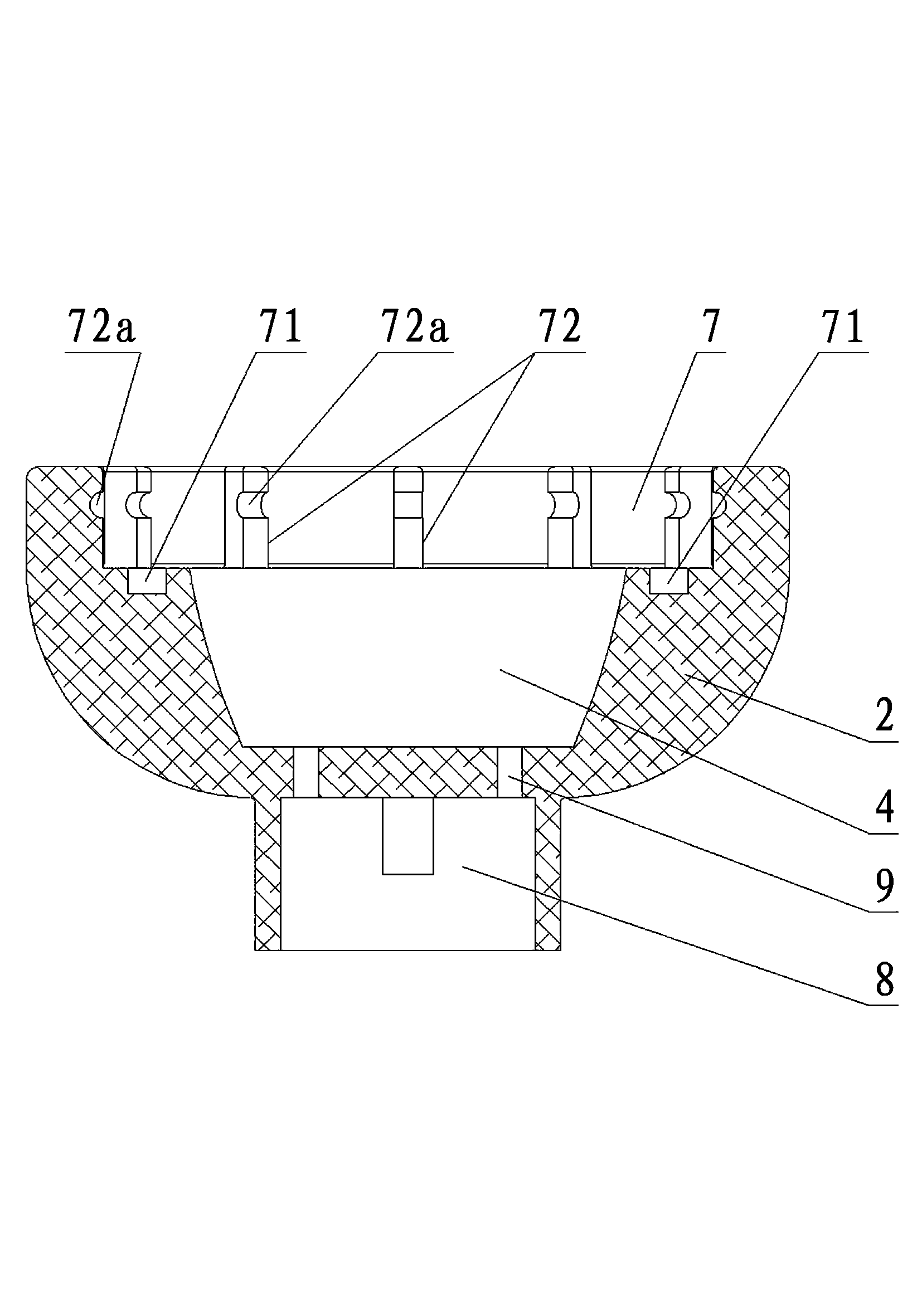

[0027] see Figure 1 to Figure 5 , an embodiment of an implementation device for LED packaging, including an LED chip 1, a heat sink 2 and an electrical connector 3, wherein the light-emitting surface of the LED chip 1 is coated with phosphor powder 16, and the phosphor powder 16 is excited by the LED chip 1 to emit white light ; The outer wall of the radiator 2 is provided with a number of cooling fins 2a to ensure the cooling effect; the electrical connector 3 is provided with pins 3a for connecting to an external power supply. One end of the radiator 1 is a large end, and the other end is a small end. The end face of the large end of the radiator is axially provided with a light source chamber 4 in a concave cavity, and a center with a groove 5a is arranged in the light source chamber 4. Insulation layer 5, the insulation layer 5 is bonded to the bottom wall of the light source chamber 4, and the LED chip 1 is fixed in the groove 5a of the insulation layer. The material of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com