Driver casing, luminous device and lamp

A light-emitting device and driver technology, which is applied to lighting devices, components of lighting devices, cooling/heating devices of lighting devices, etc., can solve the problems of leakage of perfusion heat-dissipating glue and difficult areas to cover, etc., and achieve the effect of improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

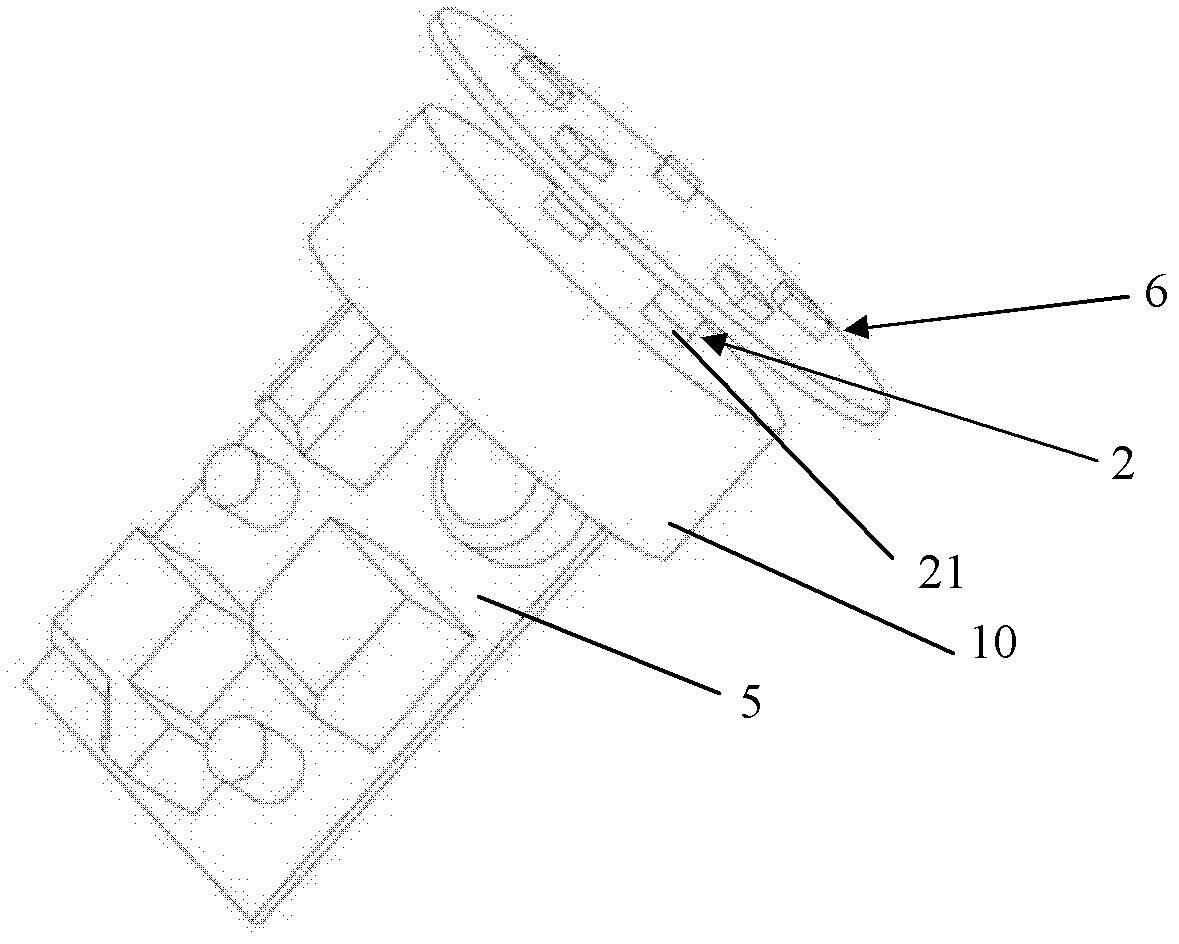

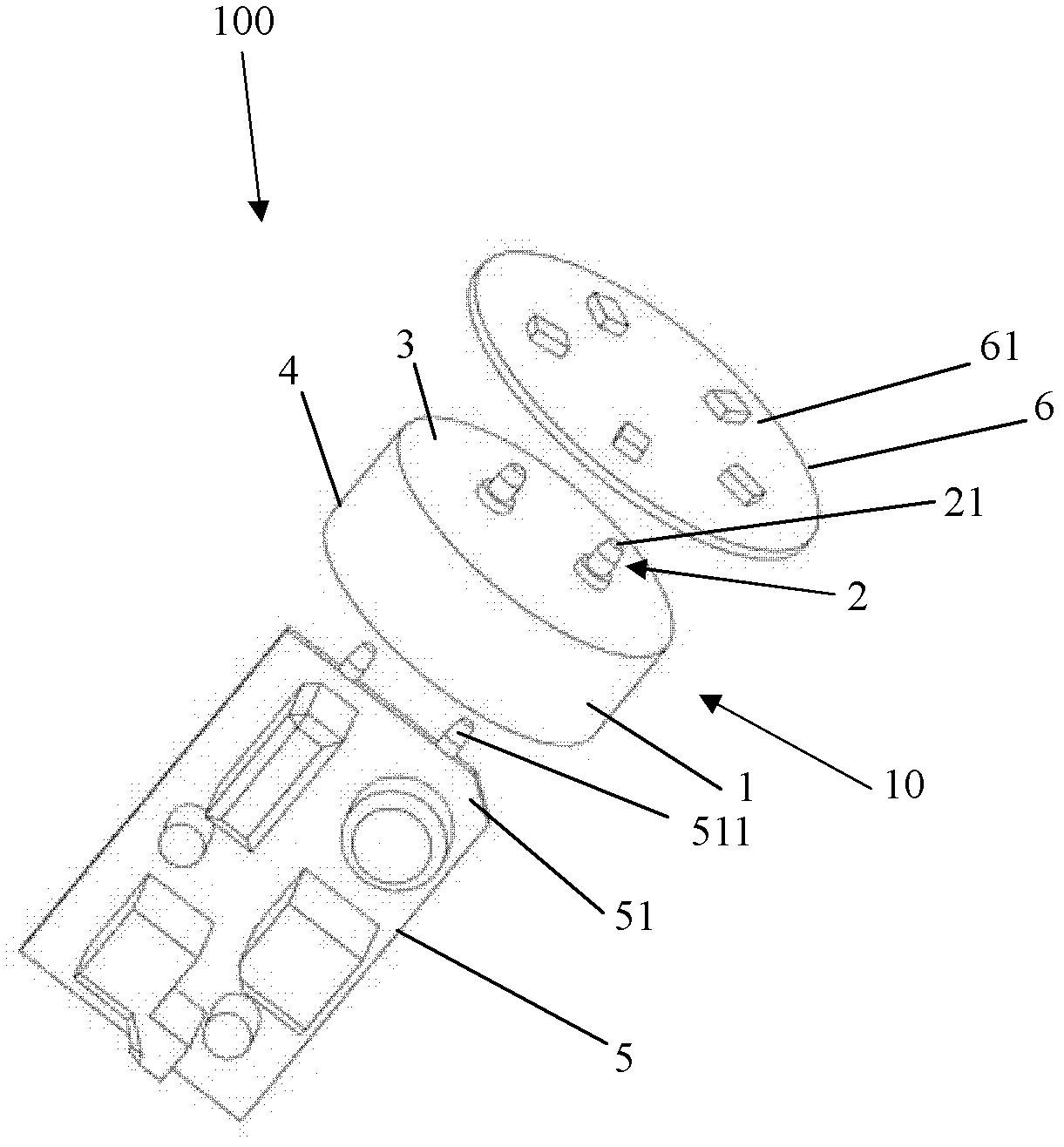

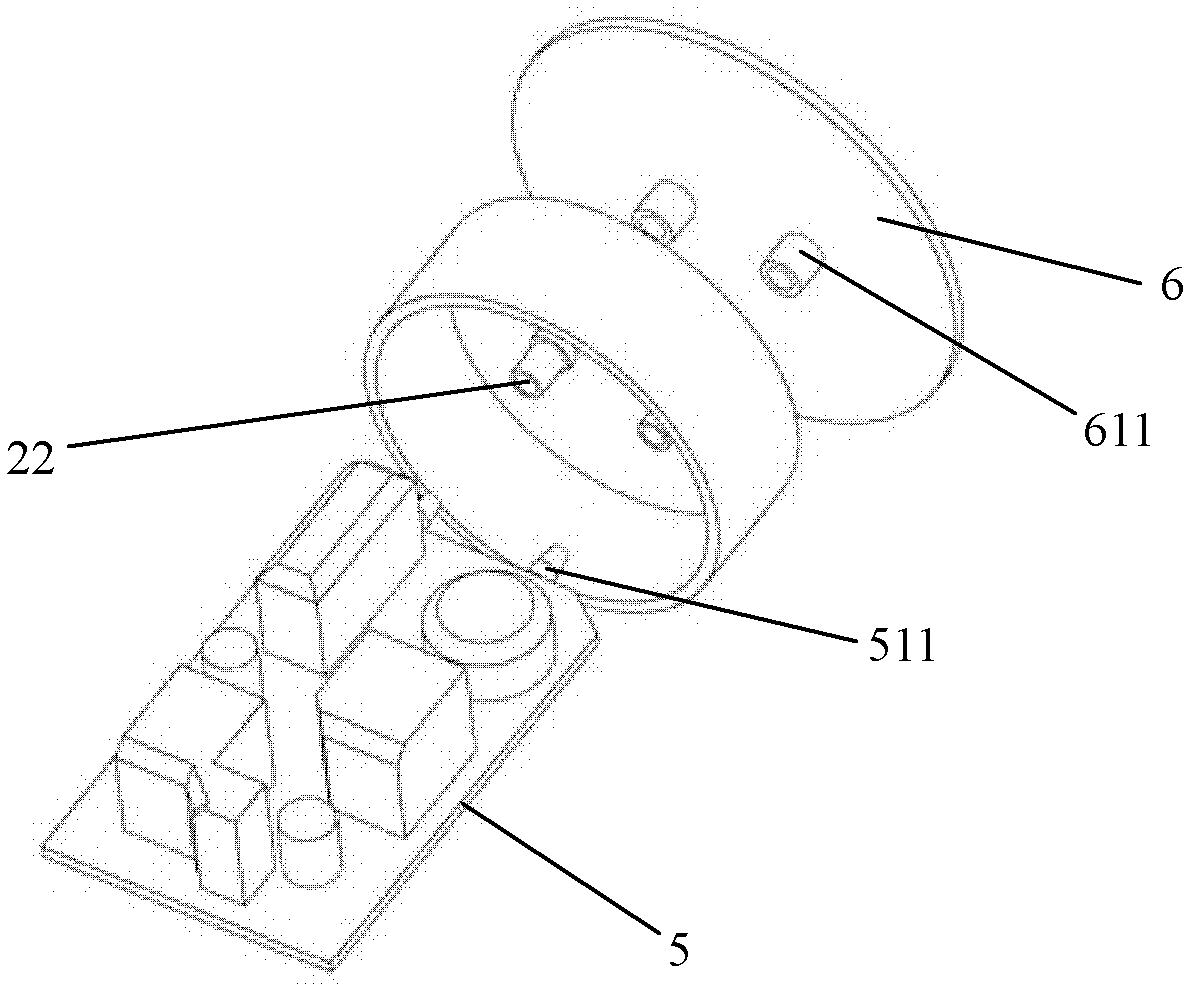

[0027] figure 1 is a perspective view of the light emitting device 100 according to the first embodiment of the present invention. figure 2 , 3 are the first and second exploded views of the light emitting device 100 according to the first embodiment of the present invention. A drive housing 10 according to the invention is shown therein.

[0028] The driver housing 10 according to the invention mainly comprises two parts: a first part 1 and a plurality of second parts 2 . The first part 1 is an electrically insulating part and the second part 2 is a conductive part. The driver housing 10 has a base 3 and a peripheral wall 4 defined by a first part 1, and a second part 2 is formed through the base 3, and the second part 2 is a pair of conductive posts separated from each other, and the conductive posts respectively pass through the base 3 extends and has contact terminals exposed on both sides of the base 3, the paired contact terminals are respectively used for positive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com