Solar cell module and packaging method

A technology of solar cells and solar cells, applied in electrical components, circuits, photovoltaic power generation, etc., can solve the problems of large occupied volume, large proportion of finished products, low power density, etc., achieve low component density, smooth surface, and reduce material consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

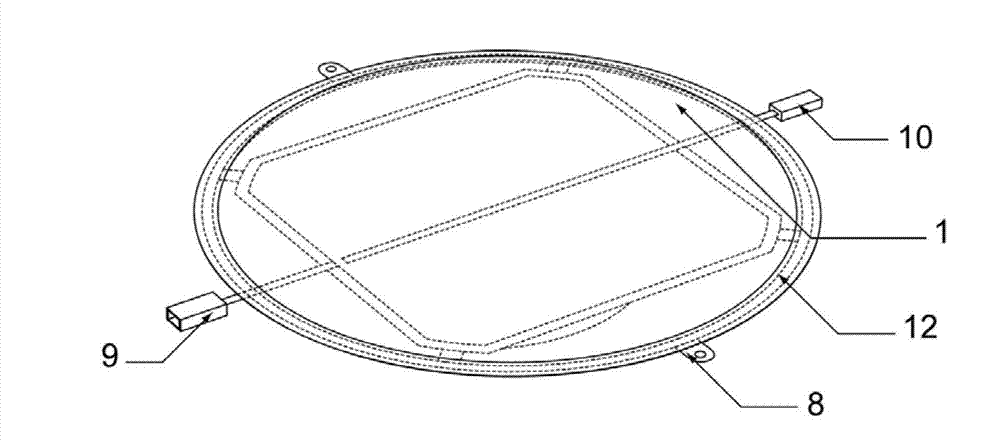

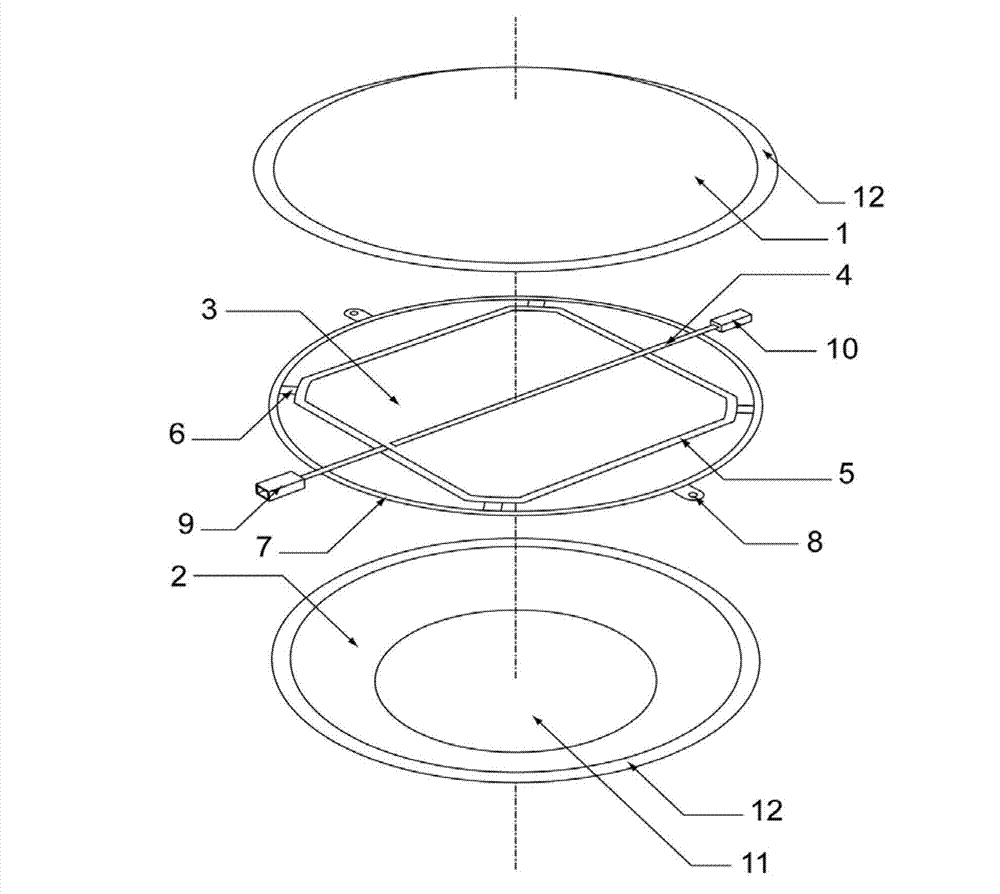

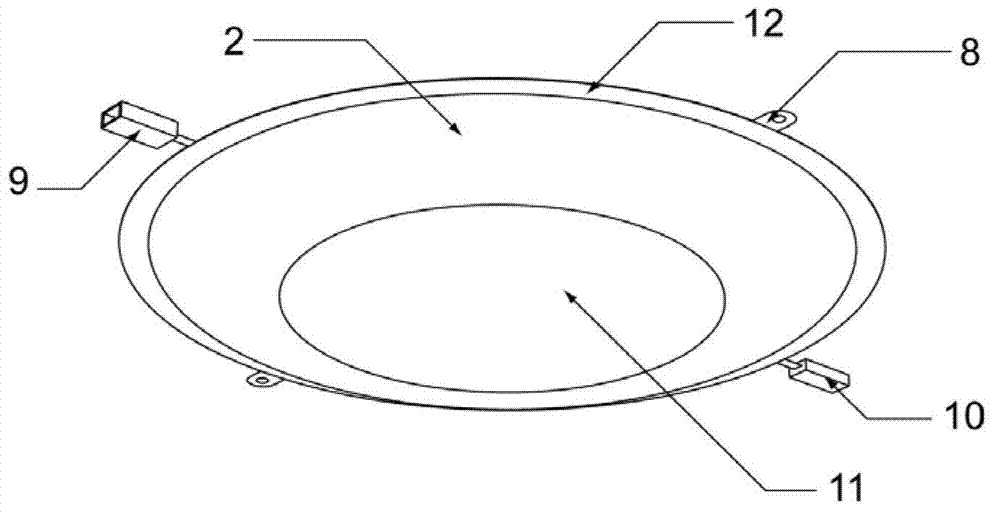

[0030] Such as Figure 1-3 As shown, the solar battery assembly of the present invention is composed of several solar battery sheet packaging monomers.

[0031] The solar cell packaging unit includes solar cells 3, reinforcing patches 5, reinforcing hoops 7, elastic connecting sheets 6, elastic films, packaging gases, flexible conductive soldering strips 4, external interfaces 11, and connecting plugs. Wherein the solar cells 3 are monocrystalline silicon cells, polycrystalline silicon cells or other sheet-shaped fragile solar cells. The positive and negative poles of the solar cell 3 are welded with the flexible conductive ribbon 4, and the back of the solar cell 3 is pasted with an insulating lightweight reinforcing patch 5 slightly larger than the solar cell or battery string, the reinforcing patch 5 and the reinforcing hoop 7 are connected with elastic connecting piece 6. The elastic film is distributed on the top and bottom of the sheet-like combination formed by the so...

Embodiment 2

[0043] Such as Figure 6-7 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the structure of the reinforcing ribs has been improved. In this embodiment, the reinforcing hoop 7 is a grid with holes, and the solar cells 3 pass through the elastic connecting piece 6 Fits in the holes of the grid. The solar cells are connected in series and parallel in a preset matrix form, with reinforcement patches on the back, the reinforcement patches are connected on the same plane or plane grid through elastic connecting pieces, and the grid is surrounded by a continuous raised transparent elastic film seal. The enclosing space is filled with the encapsulating gas of the first embodiment, and there are gaps communicating between each protrusion. The positions of the protrusions of the transparent elastic film material correspond to the positions of the solar cells one by one, and the shape of the protrusions can be the shape d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com