Integrally extrusion-molded object and building member

An extrusion molding and one-piece technology, which is applied in the field of one-piece extrusion molding and construction components, can solve the problems of reduced adhesion, easy peeling and floating of the covering layer, and achieves improved adhesion and excellent adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0109] (Examples 1-8 / Comparative Examples 1-3)

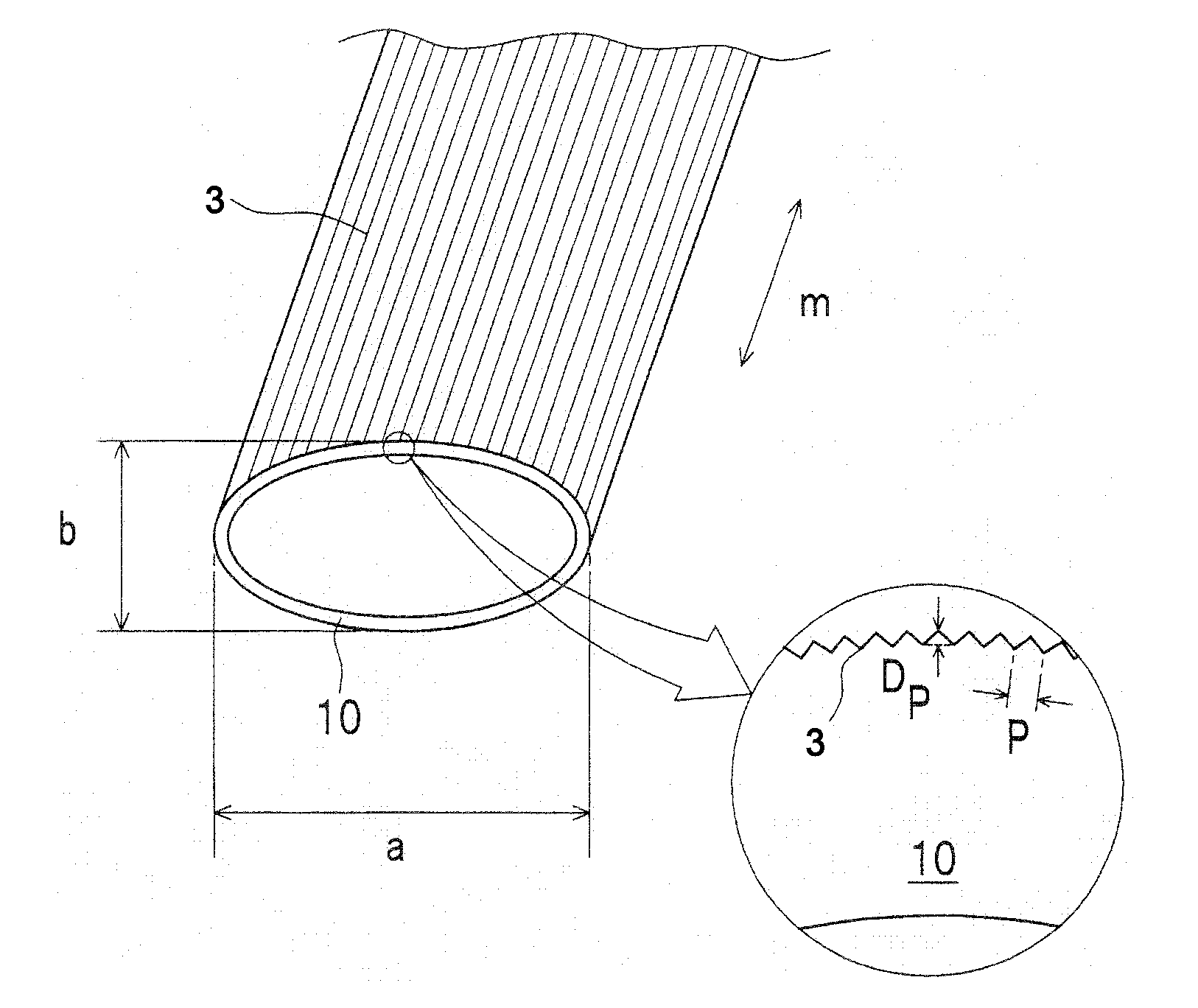

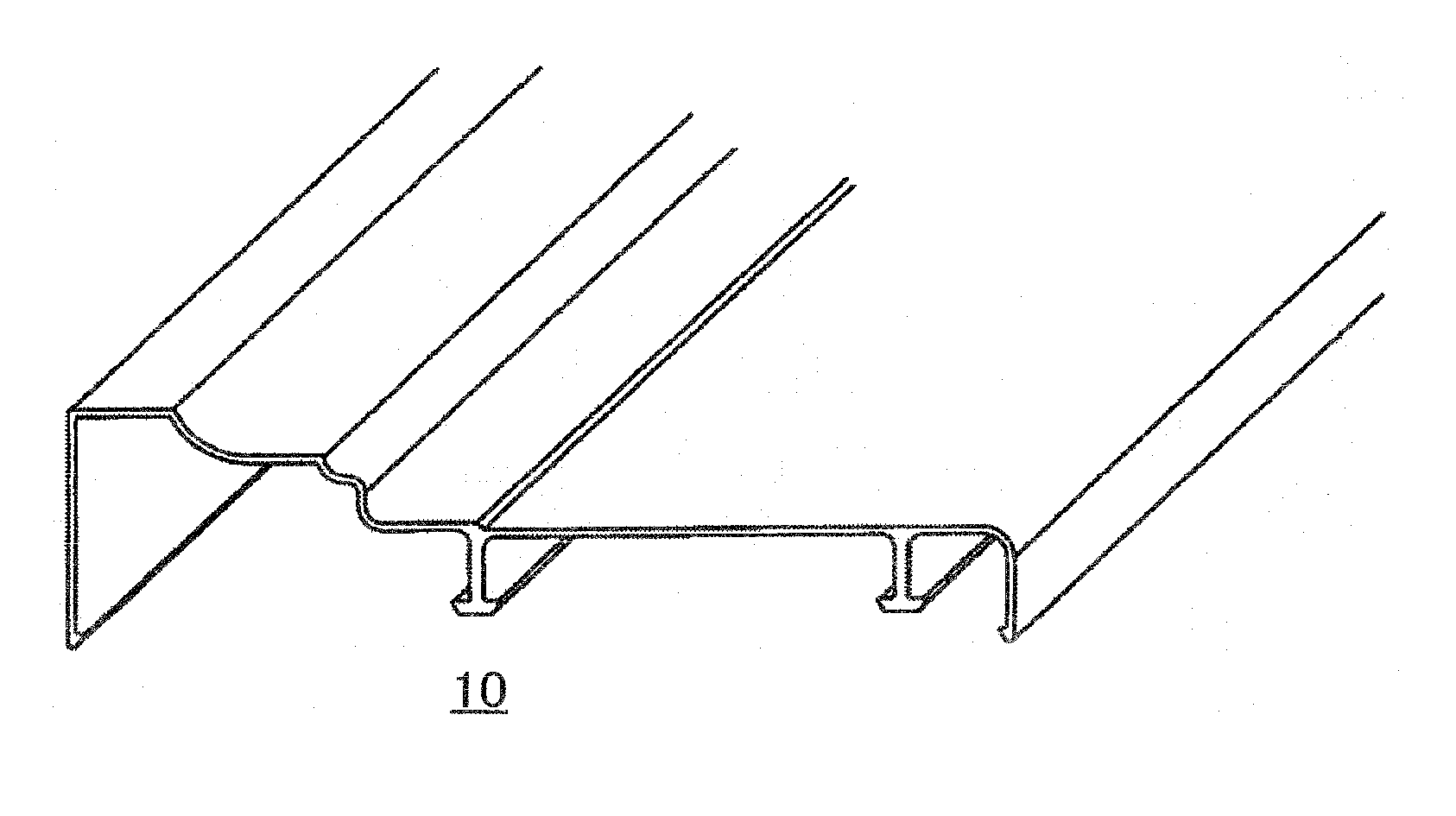

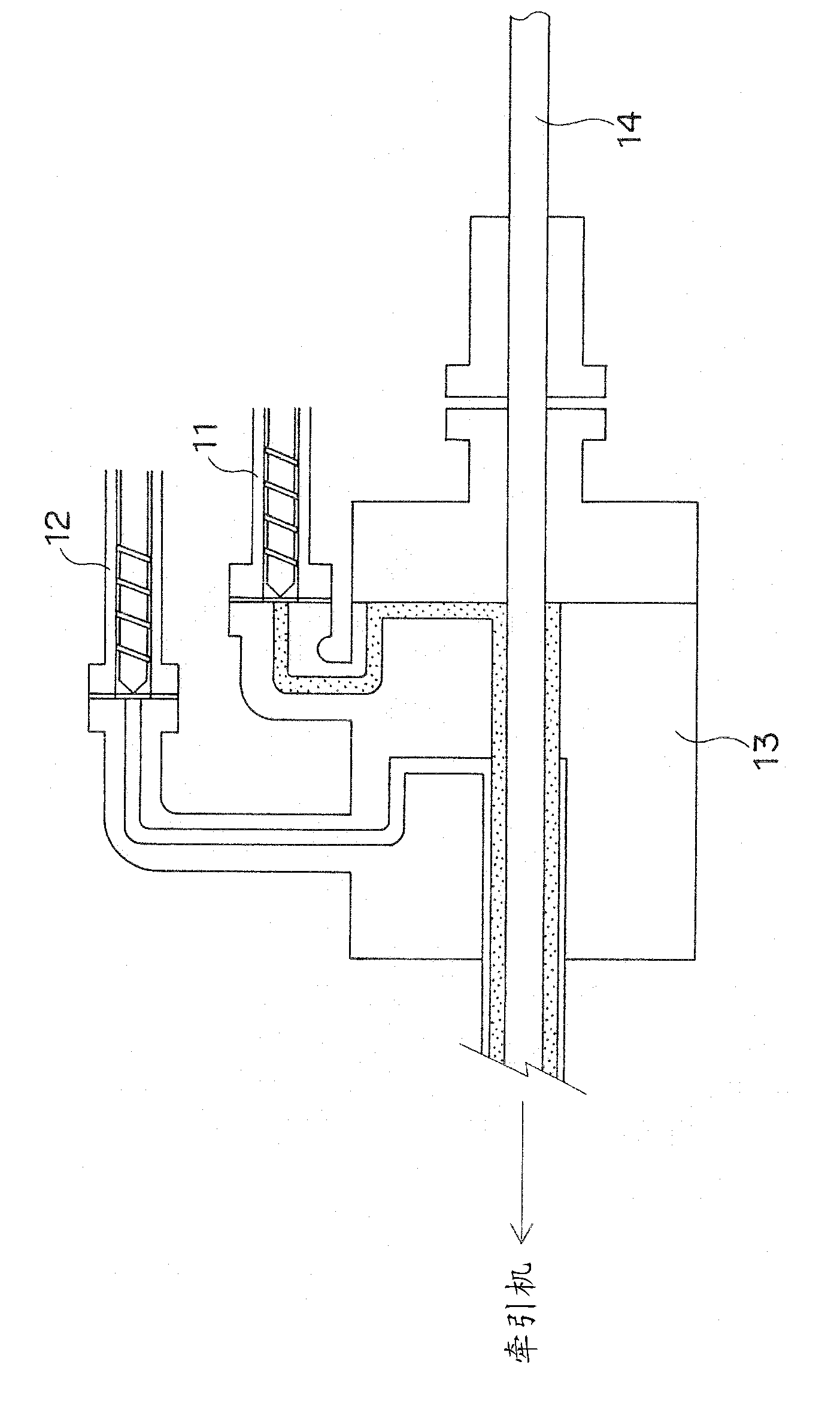

[0110] A co-extruded integrated extrusion molding machine is used to manufacture an integrally extruded molded body. Specifically, the materials for the adhesive layer and the materials for the covering layer shown in Table 1 were simultaneously extruded from the extruder 11 and the extruder 12 respectively, laminated and coated on the aluminum core material 10 in the mold 13, and produced It is an integrally extruded body that has an adhesive layer and a coating layer on the entire circumference of the outer surface of the aluminum core material. In addition, extrusion conditions and core material conditions are as follows.

[0111] Extruder 11: 40φ, single-screw extruder (extrusion temperature is about 140°C)

[0112] Extruder 12: 50φ, single-screw extruder (extrusion temperature is about 165°C)

[0113] For aluminum core materials, preheating (approximately 100°C) is performed just before insertion into the mold.

[0114]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com