Composition for increasing bone mineral density

A composition and bone density technology, applied in food science, application, food preparation, etc., can solve problems such as no significant improvement in calcium supplementation effect, single formula, and slow upgrading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

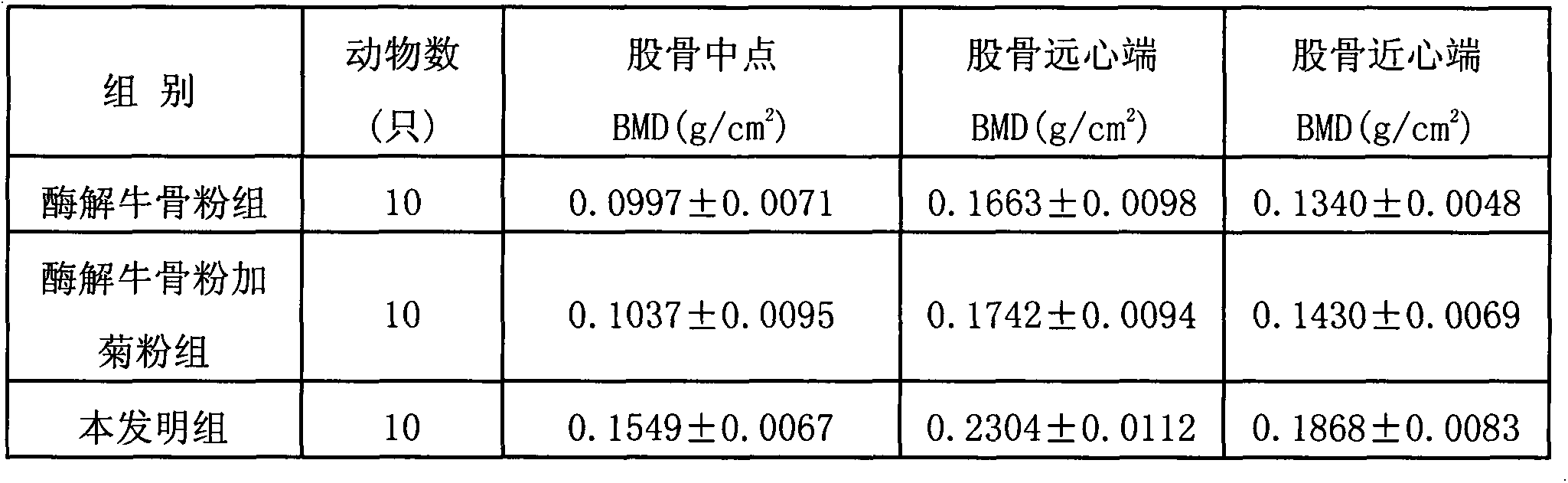

Examples

Embodiment 1

[0053] Embodiment 1: A composition for improving bone density, its raw materials and parts by weight are: 20 parts of enzymatically hydrolyzed bovine bone powder, 55 parts of DHA algae oil, and 5 parts of inulin. Add auxiliary materials to make soft capsules or dropping pills.

[0054] The method for preparing the enzymatic bovine bone powder used in this example includes: bone crushing and sterilization; taking Bifidobacterium lactis (B.lactis), Lactobacillus bulgaricus (L.bulgaricus) and Lactobacillus helveticus (L.helviticus), three The weight ratio of lactic acid bacteria is 3:1:2; the weight volume ratio of aggregate to water is 1:3, the weight ratio of lactic acid bacteria to aggregate is 0.05%, add 6% sucrose of the total weight, ferment at 45°C for 16h, and sterilize at 120°C 30min; add hydrochloric acid to adjust the pH value to 2, add pepsin, accounting for 0.09% of the aggregate weight ratio, hydrolysis temperature 37 ° C, stir for 30 minutes, add alkali to adjust t...

Embodiment 2

[0055] Embodiment 2: A composition for improving bone density, its raw materials and parts by weight are: 26 parts of enzymatically hydrolyzed bovine bone powder, 65 parts of DHA algae oil, and 11 parts of inulin. Add auxiliary materials to make soft capsules or dropping pills.

[0056] The method for preparing the enzymatic bovine bone powder used in this example includes: bone crushing and sterilization; taking Bifidobacterium lactis (B.lactis), Lactobacillus bulgaricus (L.bulgaricus) and Lactobacillus helveticus (L.helviticus), three The weight ratio of lactic acid bacteria is 3:1:2; the weight volume ratio of aggregate to water is 1:5, the weight ratio of lactic acid bacteria to aggregate is 0.05%, add 6% sucrose of the total weight, ferment at 50°C for 16h, and sterilize at 120°C 30 minutes; add hydrochloric acid to adjust the pH value to 3, add pepsin, accounting for 0.09% of the aggregate weight ratio, hydrolysis temperature 40°C, stir for 30 minutes, add alkali to adju...

Embodiment 3

[0057] Embodiment 3: A composition for improving bone density, its raw materials and parts by weight are: 23 parts of enzymatically hydrolyzed bovine bone powder, 60 parts of DHA algae oil, and 8 parts of inulin. Add auxiliary materials to make soft capsules or dropping pills.

[0058] The method for preparing the enzymatic bovine bone powder used in this example includes: bone crushing and sterilization; taking Bifidobacterium lactis (B.lactis), Lactobacillus bulgaricus (L.bulgaricus) and Lactobacillus helveticus (L.helviticus), three The weight ratio of lactic acid bacteria is 3:1:2; the weight volume ratio of aggregate to water is 1:4, the weight ratio of lactic acid bacteria to aggregate is 0.05%, add 6% sucrose of the total weight, ferment at 48°C for 16h, and sterilize at 120°C 30 minutes; add hydrochloric acid to adjust the pH value to 3, add pepsin, accounting for 0.09% of the aggregate weight ratio, hydrolysis temperature 39 ° C, stir for 30 minutes, add alkali to adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com