Method for regenerating desulfurizer treating ferric hydroxide as active component

A technology of iron oxyhydroxide and active components, applied in separation methods, chemical instruments and methods, separation of dispersed particles, etc., can solve the problem of low oxidation efficiency of waste powder, reducing oxidation efficiency of waste powder, and waste of amorphous iron oxyhydroxide. It can improve the oxidation efficiency, improve the regeneration efficiency, and improve the solubility of the problem of reducing the regeneration efficiency of the agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take α-iron oxyhydroxide as the active component desulfurizer waste agent 2kg, use a mixer to crush it into a powder with a particle size of 30 mesh, add water to the waste agent powder to form a suspension containing 2.5wt.% waste agent powder, Sodium hydroxide solution is added in the suspension, and the pH value of the suspension is adjusted to be 7.5; In the suspension, the oxygen-containing gas with a flow rate of 50L / h is passed into the suspension, and the oxygen-containing gas is a mixed gas of oxygen and air. The volume ratio of oxygen and air in the mixed gas is 6: 1, react for 5 hours, the iron sulfide in the suspension is oxidized into iron oxyhydroxide and sulfur element; then pass into the air in the suspension, the sulfur element overflows and After being separated, the remaining suspension containing precipitated ferric oxyhydroxide was filtered and washed with a centrifuge, and the filter cake was dried at -5°C for 24 hours to obtain ferric oxyhydroxide....

Embodiment 2

[0030] Get 4kg of desulfurizer waste agent with β-iron oxyhydroxide as the active component, use a mixer to crush it into a powder with a particle size of 40 mesh, add water to the waste agent powder to form a suspension containing 30wt.% waste agent powder, and add Potassium hydroxide is added to the suspension to adjust the pH of the suspension to 11; the flow rate of the suspension is 400L / h of oxygen-containing gas, and the oxygen-containing gas is a mixed gas of oxygen and air. The volume ratio of oxygen and air in the medium is 2:1, and react for 5 hours to oxidize the iron sulfide in the suspension into iron oxyhydroxide and sulfur element; then pass air into the suspension, and the sulfur element overflows and is separated , the remaining suspension containing iron oxyhydroxide precipitation was filtered and washed by a centrifuge, and the filter cake was dried at 120° C. for 3 hours to obtain iron oxyhydroxide.

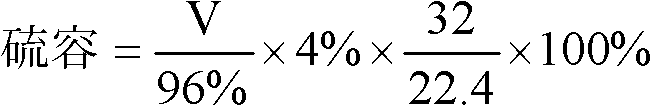

[0031] The sulfur capacity of the iron oxyhydroxide des...

Embodiment 3

[0033] Take β-iron oxyhydroxide as the desulfurizer waste agent 5kg of active component, utilize the mixing mill to be broken into particle size and be the powder of 80 meshes, add water to the waste agent powder and be made into the suspension that contains 25wt.% waste agent powder, to Lithium hydroxide is added to the suspension to adjust the pH of the suspension to 9; an oxygen-containing gas with a flow rate of 300L / h is introduced into the suspension, and the oxygen-containing gas is a mixed gas of oxygen and air. The volume ratio of oxygen and air is 3:1, react for 5 hours, the iron sulfide in the suspension is oxidized into iron oxyhydroxide and sulfur element; then air is passed into the suspension, the sulfur element overflows and is separated, The remaining suspension containing iron oxyhydroxide precipitation was filtered and washed with a centrifuge, and the filter cake was dried at 100° C. for 4 hours to obtain iron oxyhydroxide.

[0034]The sulfur capacity of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com