Energy saving reaction furnace with characteristics of easy reaction condition control and non-integral hollow spiral structure

A spiral, non-integral technology, applied in the field of energy-saving reactors, can solve the problems of high energy consumption, restrictions on the comprehensive utilization of lignite, and low efficiency, and achieve the effects of good mechanical properties, easy control, and reduced energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

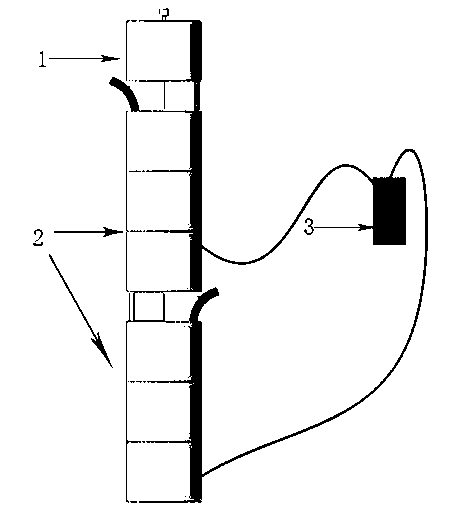

[0043] This embodiment is an energy-saving reaction furnace for pyrolysis and upgrading of lignite with a non-integral hollow spiral structure that is easy to control the reaction conditions, see Figure 1 to Figure 8 .

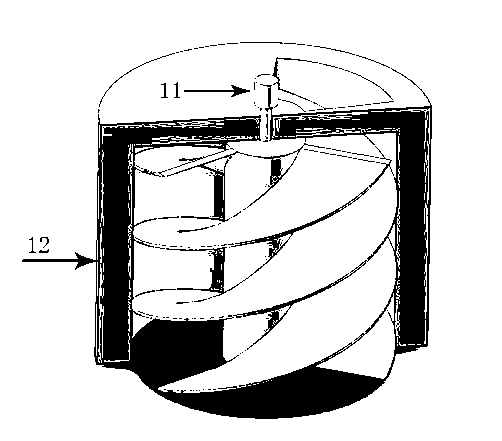

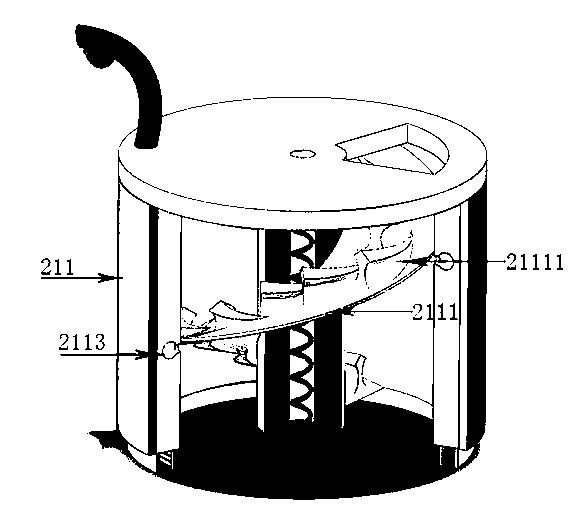

[0044] An electric feeder 1 comprising a spiral structure; one or more than one reaction compartment 2; and a programmable logic control device 3 three units. The electric feeder of the spiral structure is composed of a motor 11 and a hopper of spiral structure 12; the reaction compartment is composed of a material reaction vessel with a spiral structure and a heating device 22 placed in the heat source channel at the center of the reaction vessel ; The material reaction container of the spiral structure is composed of three metal independent integral containers 211, 212 and 213 that are surrounded by a tubular shaft with a single-head spiral blade 2111 and a tubular outer sleeve of the spiral blade through casting integrally formed formed; the tubular shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com