On-line oil coating device for steel stranded wires

An oiling device and a technology for steel strands, which are applied in the directions of devices and coatings that apply liquid to the surface, can solve the problem of small contact area between strands of strands, large waste of grease on the surface of strands, and sanitary production site. problems such as large impact, to achieve the effect of being conducive to promotion and implementation, comprehensive oiling, easy processing and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

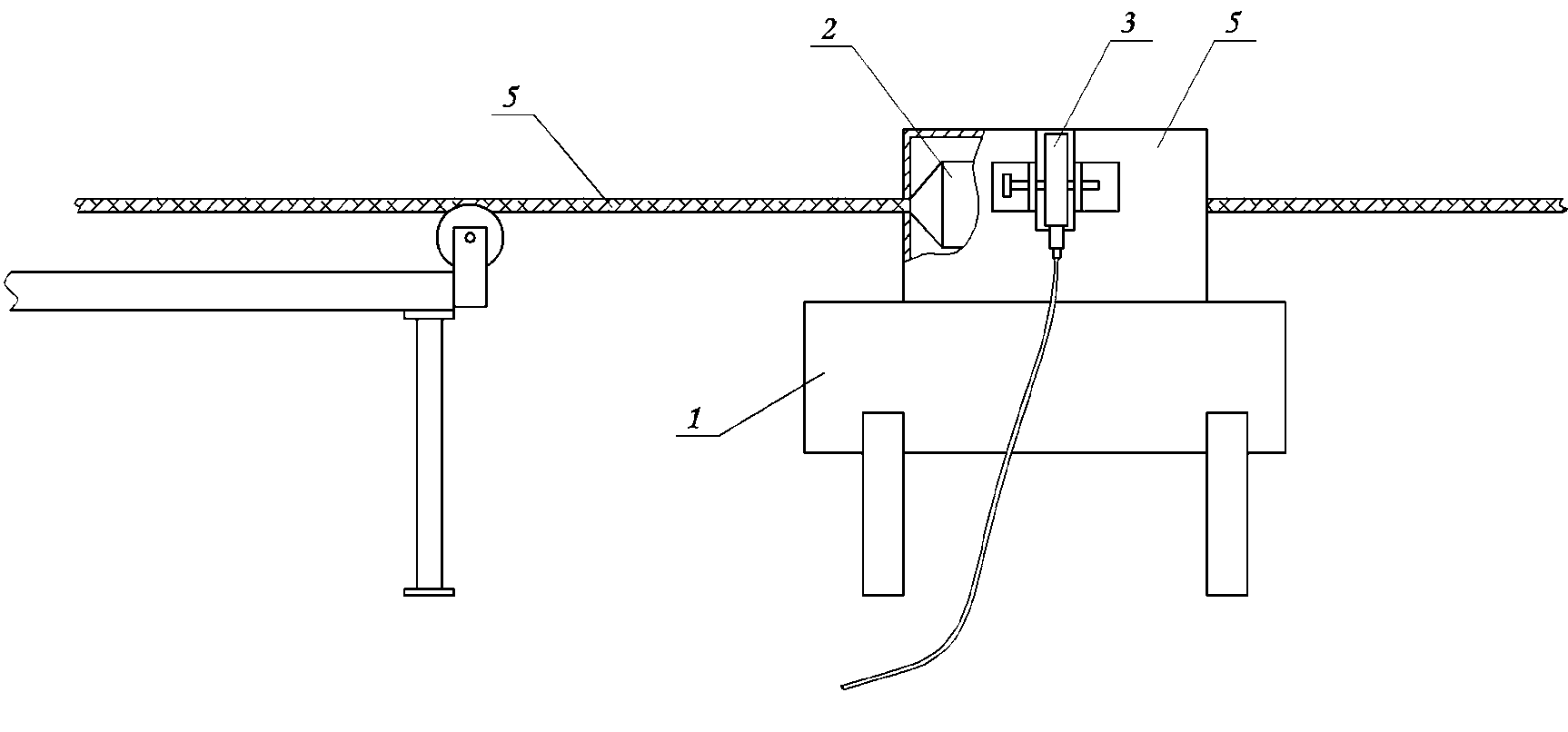

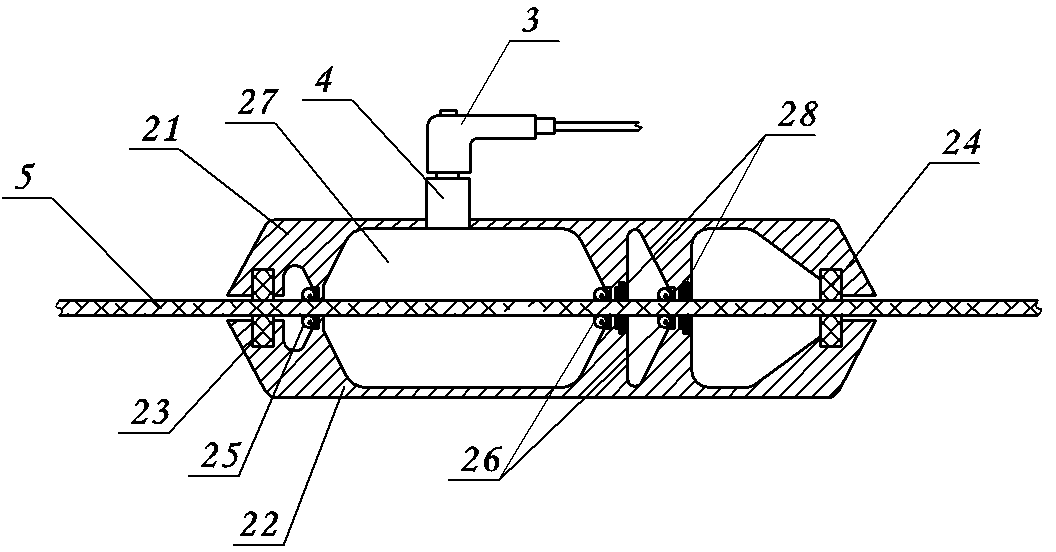

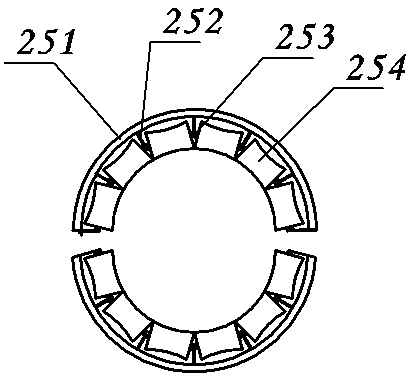

[0016] Such as figure 1 , a housing 5 is provided on the bracket 1, an oiling device 2 is installed in the housing 5, and the oiling device 2 is movably installed in the housing 5, and the oiling device 2 can be replaced according to the oiling requirements of different steel strand models. Such as figure 2 , The oiling device includes an upper cover 21 and a lower cover 22, one side of the upper cover 21 and the lower cover 22 are hinged together, and the other side is provided with a locking mechanism. There is a sealed high-pressure chamber 27 between the upper cover 21 and the lower cover 22 after fastening, and the front and rear ends of the upper cover 21 and the lower cover 22 are respectively provided with a front gasket 23 and a rear gasket 24 . There is a front extruding mechanism 25 and a rear extruding mechanism 26 in the high pressure chamber 27 . A tarpaulin layer 28 is provided on the rear side of the pressing wheel of the rear pressing mechanism 26 . The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com