A method for tanning sheepskin with organic amine synergistic epoxy resin composition tanning agent

A technology of epoxy resin and composition, applied in leather impregnation, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., to achieve structural stability and improve moisture and heat resistance stability Sex, the effect of reducing the tanning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

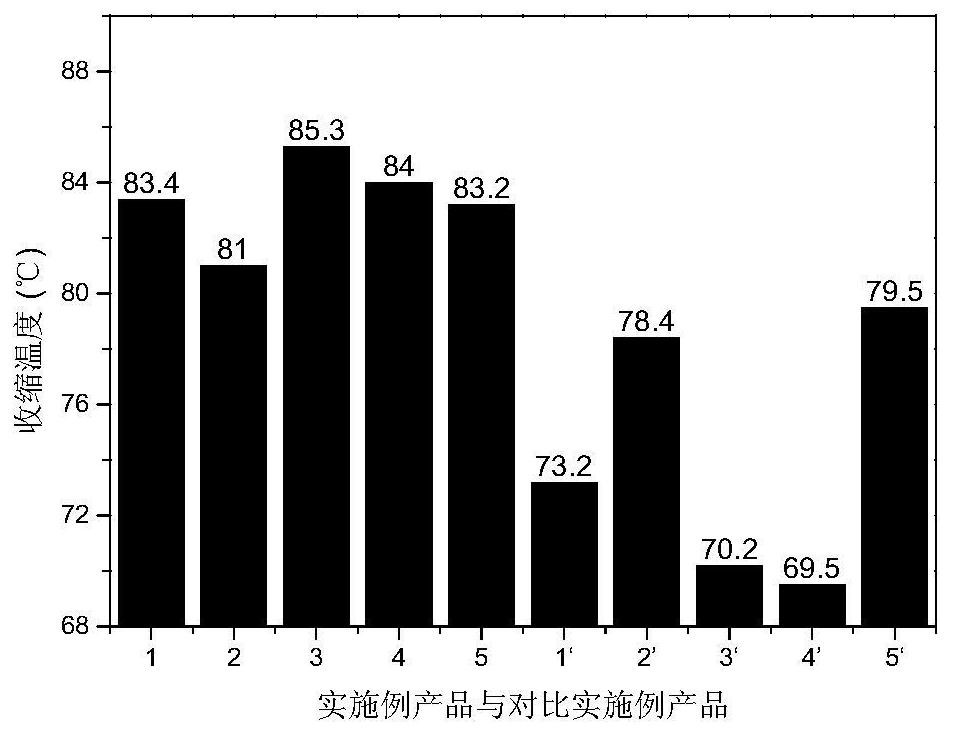

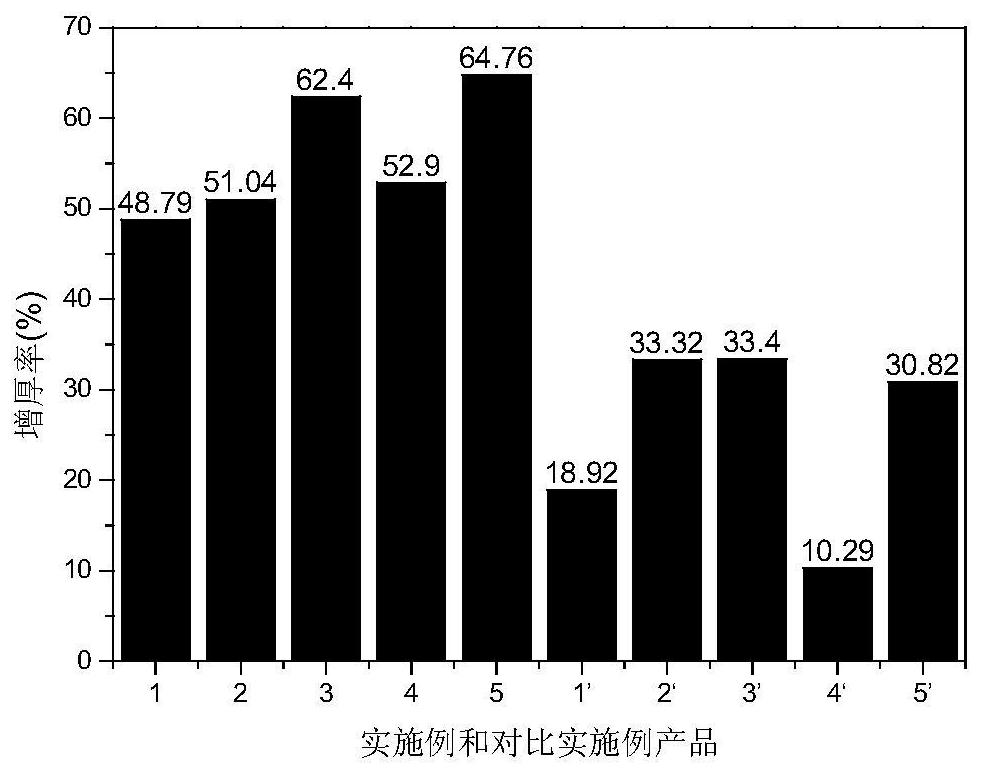

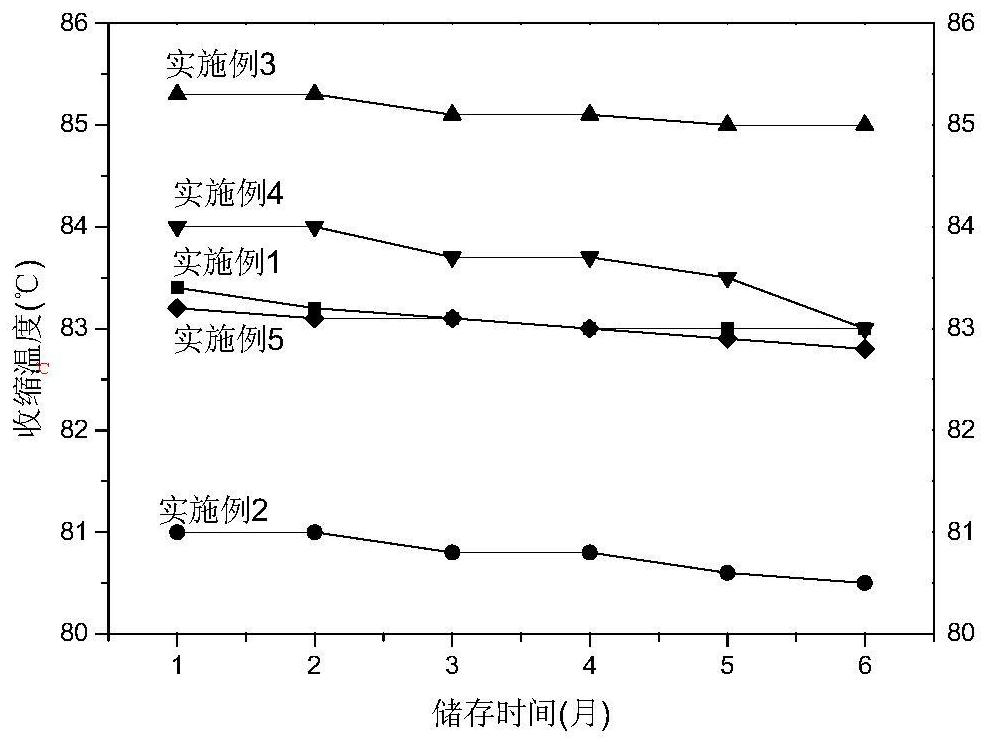

Examples

Embodiment 1

[0044] In this embodiment, the sheepskin after conventional deliming and softening is put into a drum for tanning:

[0045] First, in the melamine bath solution with a liquid ratio of 80% and a concentration of 1.0%, it is treated by turning at 35°C for 60 minutes, then adding an epoxy resin composition tanning agent with a concentration of 10%, turning at 40°C for 1 hour, turning at 50°C for 8 hours, replenishing water, Let it stand overnight, turn it for at least 30 minutes the next day, then control the water and wash it sequentially, use acetic acid solution (acetic acid: water = 1:10 (mass ratio)) to adjust the pH value of the system to 5.5-6.0, then turn it for at least 30 minutes, and take out the drum. Subsequent processing can be carried out as usual.

[0046] Wherein the epoxy resin composition tanning agent used is made up of epoxy resin X and epoxy resin Y with a mass ratio of 5:1, glycerol triglycidyl ether and ethylene glycol diglycidyl ether contained in epoxy r...

Embodiment 2

[0050] In this embodiment, the sheepskin after conventional deliming, softening (degreasing is carried out simultaneously in the softening process, and the pH value is adjusted to 7.5 to 8.0 with baking soda), and pickled is put into a drum for tanning:

[0051] First, in the dicyandiamide bath solution with a liquid ratio of 90% and a concentration of 0.5%, turn it at 40°C for 30 minutes, then add an epoxy resin composition tanning agent with a concentration of 6%, turn it at 38°C for 2 hours, and turn it at 45°C for 10 hours. Replenish the water, let it stand overnight, turn it for at least 30 minutes the next day, then control the water and wash it with water, use formic acid solution (formic acid: water = 1:10 (mass ratio)) to adjust the pH value of the system to 5.5-6.0, turn it for at least 30 minutes, and take out the drum After riding the horse, the subsequent process can be carried out as usual.

[0052] Wherein the epoxy resin composition tanning agent used is to be ...

Embodiment 3

[0056] In this embodiment, the sheepskin after conventional deliming and softening is put into a drum for tanning:

[0057] First, in the amino resin (melamine and formaldehyde polymer, the molar ratio of melamine and formaldehyde is 1:5) bath solution with a liquid ratio of 80% and a concentration of 0.8%, turn it at 30°C for 50 minutes, and then add epoxy resin with a concentration of 12%. Resin composition tanning agent, rotate at 35°C for 1 hour, rotate at 48°C for 10 hours, replenish water, let stand overnight, turn for at least 30 minutes the next day, then control water and wash in turn, use acetic acid solution (acetic acid: water = 1:10 (mass ratio) ) to adjust the pH value of the system to 5.5-6.0, and then rotate for at least 30 minutes, and then proceed to the follow-up process as usual.

[0058] Wherein the epoxy resin composition tanning agent used is made up of epoxy resin X and epoxy resin Y with a mass ratio of 4:1, glycerol triglycidyl ether and ethylene glyc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com