Surface-functionalized spherical nano silicon dioxide-graphene oxide/polymer-based compound tanning agent and preparation method thereof

A technology of surface functionalization and compound tanning agent, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, tanning treatment, etc., can solve the problem of chrome-free tanning agent It is difficult to meet the requirements of good use performance of finished leather, the shortage of chromium resources, toxicity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

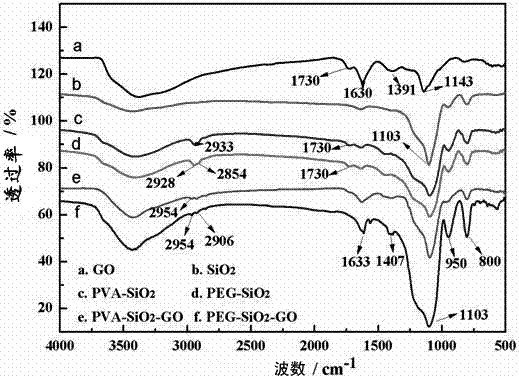

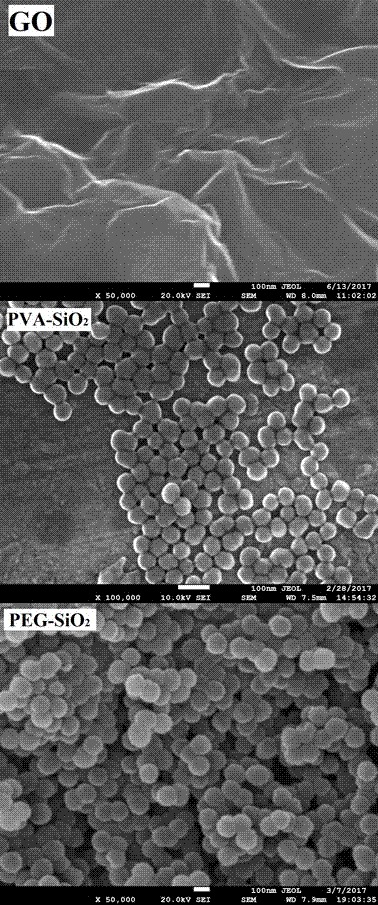

[0028] 2. Preparation of Graphene Oxide Nanosheets

[0029] 1 g of natural flake graphite powder (Sinopharm Chemical Reagent Co., Ltd., Spectrum Pure) was slowly added to 25 mL of concentrated sulfuric acid in an ice-water bath and stirred at a low speed, and mixed well to obtain the reaction solution ①. Weigh 5 g of potassium permanganate and add it to the reaction solution ① in batches under ice-water bath and low-speed stirring, and complete the addition within 1 hour. After the addition, react at room temperature for 2 hours until the reaction solution turns dark green to obtain the reaction solution ②. Continuously and slowly inject deionized water into the reaction solution ②, control the temperature of the reaction system below 100 °C, dilute the reaction solution ② to 80-100 mL, then add 5-10 mL 5v % hydrogen peroxide until the solution turns bright yellow, Check the pH of the supernatant to be 7, and filter while hot. The product was fully washed with 5 wt% dilute h...

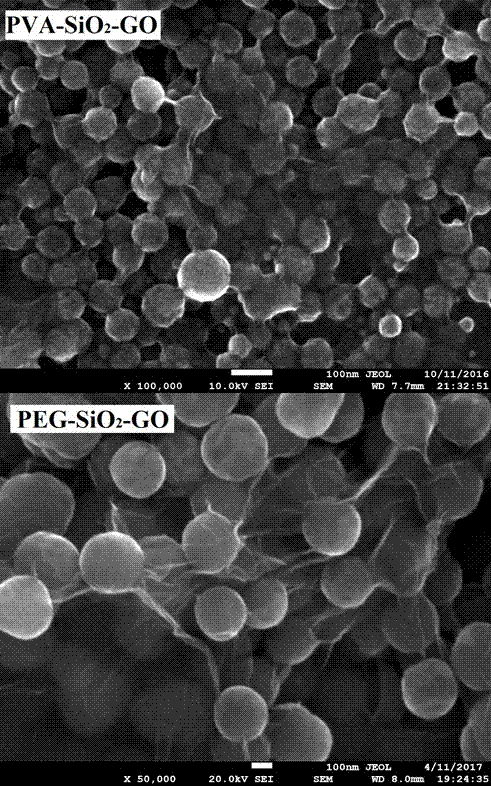

Embodiment 123

[0034] Example 1 23 g of maleic anhydride was fully dissolved in 100 mL of deionized water at 75-85 °C to obtain the reaction solution ①; 0.30 g of PVA-SiO 2 -GO (the degree of polymerization of PVA is 1700; the mass ratio of PVA and tetraethyl orthosilicate is 1:2; PVA-SiO 2 (10:1 mass ratio to GO) was dissolved in 20 mL deionized water and ultrasonically treated for 30 minutes to obtain a uniform and stable reaction solution ②; the reaction solution ① and reaction solution ② were mixed evenly under stirring at 75-85 °C to obtain the reaction solution solution ③; 1.2 g of ammonium persulfate dissolved in 10 mL of deionized water and 36 mL of acrylic acid (AA) were slowly and evenly added dropwise to the reaction solution ③ at the same time. Finally, use 30 wt% sodium hydroxide solution to adjust the pH value of the product solution to 5-6, and discharge the material to obtain surface functionalized spherical nano-SiO 2 -graphene oxide / maleic anhydride-acrylic acid copolymer ...

Embodiment 223

[0035] Example 2 23 g maleic anhydride (MA) was fully dissolved in 100 mL deionized water at 75-85 °C to obtain reaction solution ①; 1.22 g PVA-SiO 2 -GO or PEG-SiO 2 -GO (the degree of polymerization of PVA is 1700; the molecular weight of PEG is 1500; the mass ratio of PVA, PEG and ethyl orthosilicate is 1:1; PVA-SiO 2 or PEG-SiO 2 The mass ratio to GO is 5:1) dissolved in 50 mL deionized water and ultrasonically treated for 30 minutes to obtain a uniform and stable reaction solution ②; the reaction solution ① and the reaction solution ② were mixed evenly under strong mechanical stirring at 75-85 °C , to obtain the reaction solution ③; 1.2 g of ammonium persulfate was dissolved in 10 mL of deionized water and 36 mL of acrylic acid (AA) and slowly and evenly added dropwise to the reaction solution ③ at the same time. After the reaction, use 30 wt% sodium hydroxide solution to adjust the pH value of the product solution to 5-6, and discharge the material to obtain surface fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com