Preparation method of retanning agent, retanning agent and application of retanning agent

A technology of retanning agent and sulfonated dialdehyde, applied in the field of retanning agent, can solve problems such as softness, poor firmness, health threats, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

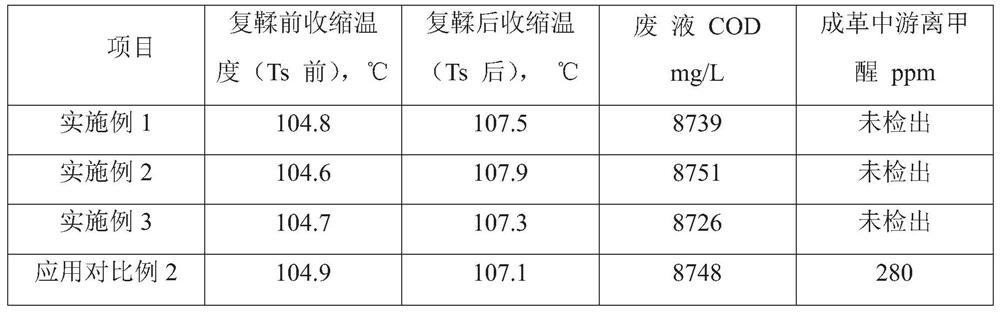

Examples

Embodiment 1

[0037] (1) Stir and mix 28.74Kg glutaraldehyde and 20.43Kg pure water at room temperature, adjust the pH value to 8.5, add 11.49Kg sodium sulfamate three times in equal parts, each time at intervals of 3 minutes, stir evenly, and then Raise the temperature to 80°C and react for 1.5 hours to obtain partially sulfonated dialdehyde;

[0038] (2) Mix 4.60Kg melamine and 29.00Kg pure water at room temperature, adjust the pH value to 8.5, then add the part sulfonated dialdehyde prepared in step (1) three times in equal parts, each interval is 10 Minutes, react at a temperature of 80°C for 1.0 hour, heat up to 85°C and continue the reaction for 20 minutes to obtain an amino resin prepolymer containing sulfonic acid groups;

[0039] (3) Add 5.75Kg of ethanol to the amino resin prepolymer containing sulfonic acid groups obtained in step (2), adjust the pH value to 4, then incubate at 60°C for 2 hours, and finally adjust the pH value to neutral to obtain amino Resin retanning agent pro...

Embodiment 2

[0042] (1) Stir and mix 45.62Kg of adipaldehyde and 20.51Kg of pure water at room temperature, adjust the pH value to 9.0, add 11.94Kg of sodium sulfite three times in equal parts, each time at intervals of 3 minutes, stir evenly, and then heat up to 75 Reaction at ℃ for 2.0 hours to obtain partially sulfonated dialdehyde;

[0043] (2) Mix 8.96Kg melamine and 28.00Kg pure water at room temperature, adjust the pH value to 9.0, then add the part sulfonated dialdehyde prepared in step (1) three times in equal parts, each interval is 10 Minutes, react at a temperature of 85°C for 0.5 hours, and continue to react for 10 minutes at a temperature of 90°C to obtain an amino resin prepolymer containing a sulfonic acid group;

[0044] (3) Add 7.46Kg of ethanol to the amino resin prepolymer containing sulfonic acid groups obtained in step (2), adjust the pH value to 5, then incubate at 60°C for 2 hours, and finally adjust the pH value to neutral to obtain amino Resin retanning agent pro...

Embodiment 3

[0047] (1) Stir and mix 22.45Kg glyoxal and 24.00Kg pure water at room temperature, adjust the pH value to 8.5, add 6.12Kg sodium sulfamate and 5.44Kg sodium sulfite three times in equal parts, with an interval of 4 minutes each time, Stir evenly, then heat up to 80°C and react for 1.5 hours to obtain partially sulfonated dialdehyde;

[0048] (2) Mix 8.16Kg melamine and 25.66Kg pure water at room temperature, adjust the pH value to 8.5, then add the part sulfonated dialdehyde prepared in step (1) three times in equal parts, each interval is 15 Minutes, react at a temperature of 85°C for 0.5 hours, heat up to 95°C and continue the reaction for 15 minutes to obtain an amino resin prepolymer containing sulfonic acid groups;

[0049] (3) Add 8.16Kg diethylene glycol to the amino resin prepolymer containing sulfonic acid groups obtained in step (2), adjust the pH value to 4, then incubate at 60°C for 2 hours, and finally adjust the pH value to neutral , to obtain amino resin retan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com