Composition for packaging photoelectric device

A technology for optoelectronic devices and compositions, applied in the direction of electrical solid devices, electrical components, semiconductor devices, etc., can solve the problems that the application of optoelectronic device packaging materials with optical properties has never been reported, and achieves improved moisture and heat resistance, high crack resistance, The effect of improving light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

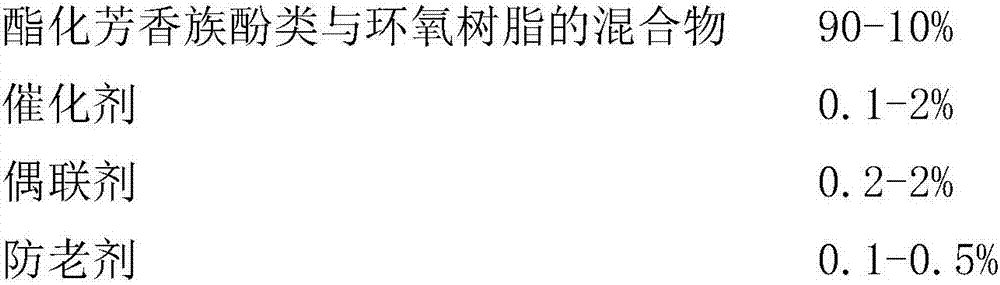

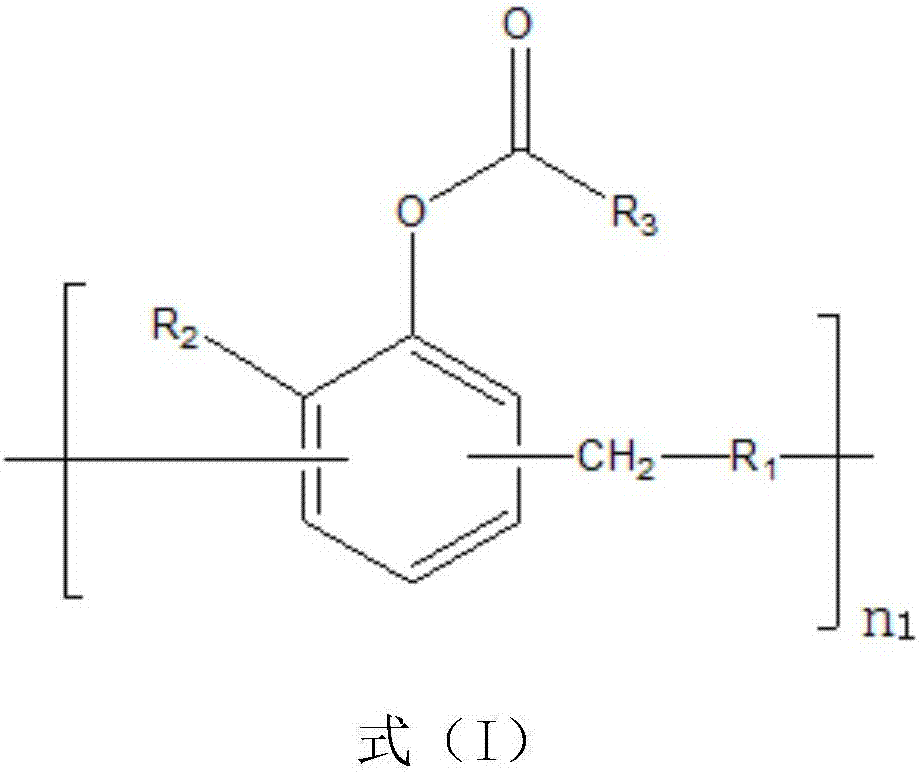

Method used

Image

Examples

preparation example Construction

[0040] (1) Preparation of ethyl esterified phenolic resin:

[0041] Weigh 200g of H-4 phenolic resin in a three-necked bottle, add 750mL of acetic anhydride to dissolve, and then add 25mL of pyridine as a catalyst. Stir continuously under the protection of nitrogen, and place it in an oil bath and heat it to 100°C. After continuing the reaction for 24 hours, heat to evaporate most of the remaining acetic anhydride and pyridine; add 1000mL of chloroform to dissolve it, and transfer it to a separatory funnel , with a mass fraction of 3% NaHCO 3 Wash the solution several times until no bubbles are released; then add pure water to wash several times, take out the organic layer of chloroform, dry it with anhydrous magnesium sulfate overnight, distill off the chloroform, and place it in a vacuum oven for further drying.

[0042] (2) Preparation of butyl esterified copolymerized phenolic resin:

[0043] Weigh 200g of MEH-7800 type resin in a three-necked bottle, add 800mL of butyri...

experiment example 1

[0047] Heat and stir 100g of epoxy resin ERL-4221 and 108g of ethyl esterified phenolic H-4 at 80°C, add 0.5g of coupling agent, 0.5g of antioxidant and 0.3g of catalyst, stir until transparent and clear, defoam and cool .

experiment example 2~7

[0049] According to the ratio in Table 1, heat and mix at 80°C, stir until transparent and clear, then defoam and cool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com