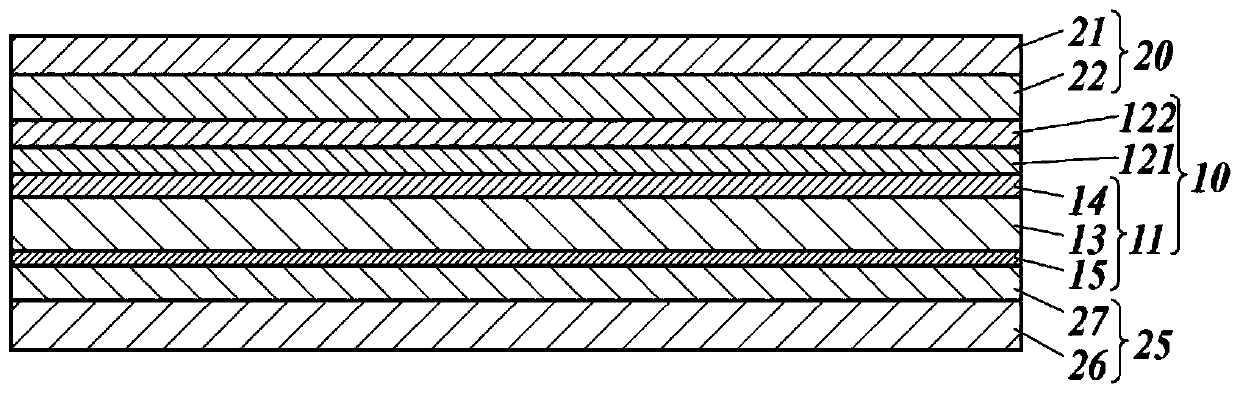

Gas barrier film and method for producing gas barrier film

A technology of gas barrier and manufacturing method, applied in the direction of surface coating liquid device, gaseous chemical plating, metal material coating process, etc., can solve the problems of high elastic modulus and insufficient crack resistance, and achieve maintenance Effects of crack resistance, resistance improvement, and high gas barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

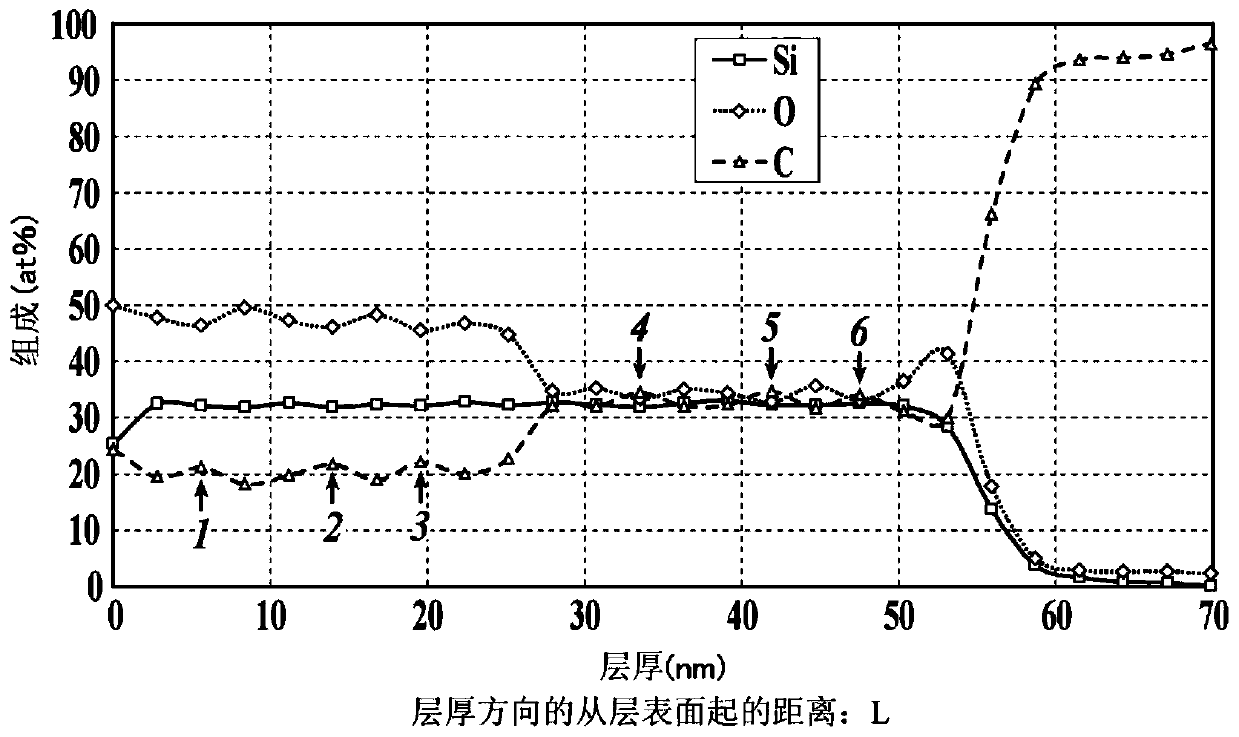

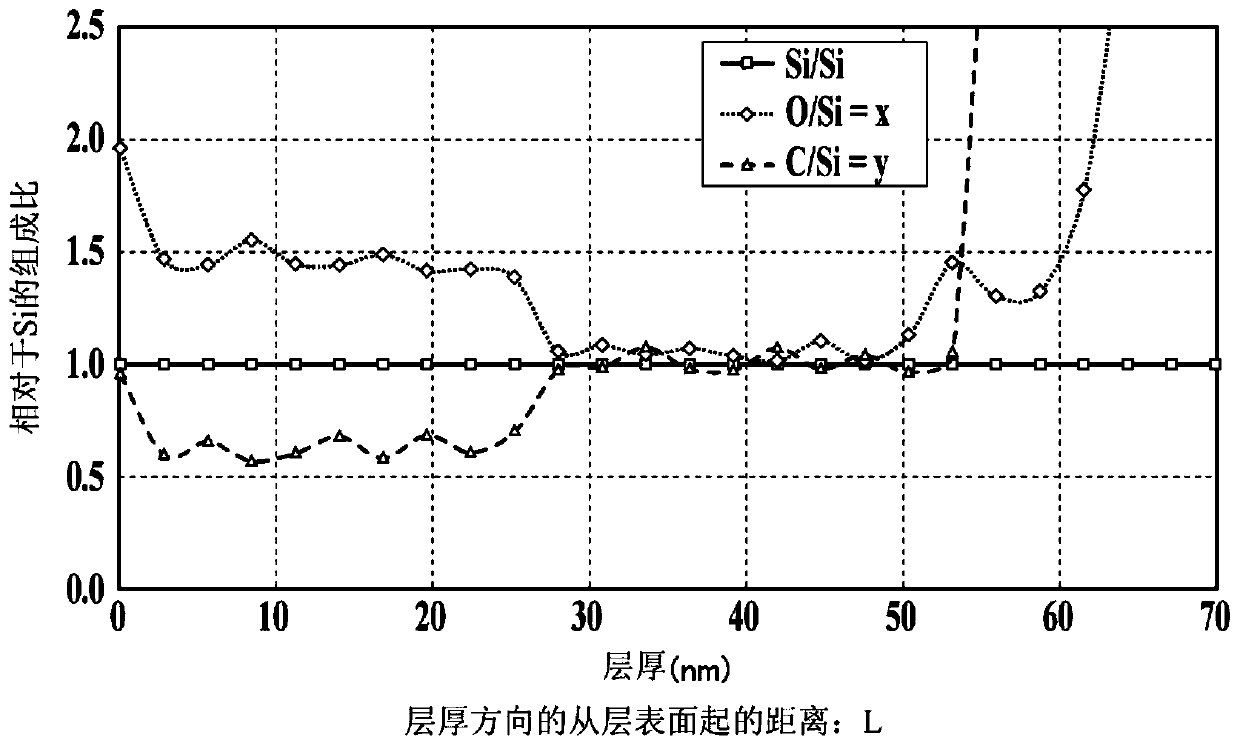

Method used

Image

Examples

Embodiment

[0332] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to these. In addition, the expression of "part" or "%" is used in an Example, Unless otherwise specified, it means "part by mass" or "% by mass".

[0333] [Making of base material]

[0334] The base material [1] in which the hard-coat layer was formed on the both surfaces of a support body was produced by the following method.

[0335] (support body)

[0336] A 50-μm-thick PET film, KFL12W#50, manufactured by Teijin DuPont Films Co., Ltd., had an easy-adhesive layer on both surfaces.

[0337] (Preparation of hard coat coating solution [HC1])

[0338] A hard coat coating solution [HC1] obtained by mixing the following materials was prepared.

[0339]

[0340] (Making of substrate [1])

[0341] Using a roll-to-roll coating device, apply the hard coat coating solution [HC1] on one side of the support (PET film) to a dry layer thickness of 4 μm and dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com