High-temperature-resistant sealing film for water vapor and preparation method of sealing film

A sealing film and high temperature resistant technology, applied in the field of high temperature resistant water vapor sealing film and its preparation, can solve the problems of reducing the thermal insulation effect, affecting the service life of thermal insulation materials, etc. The effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

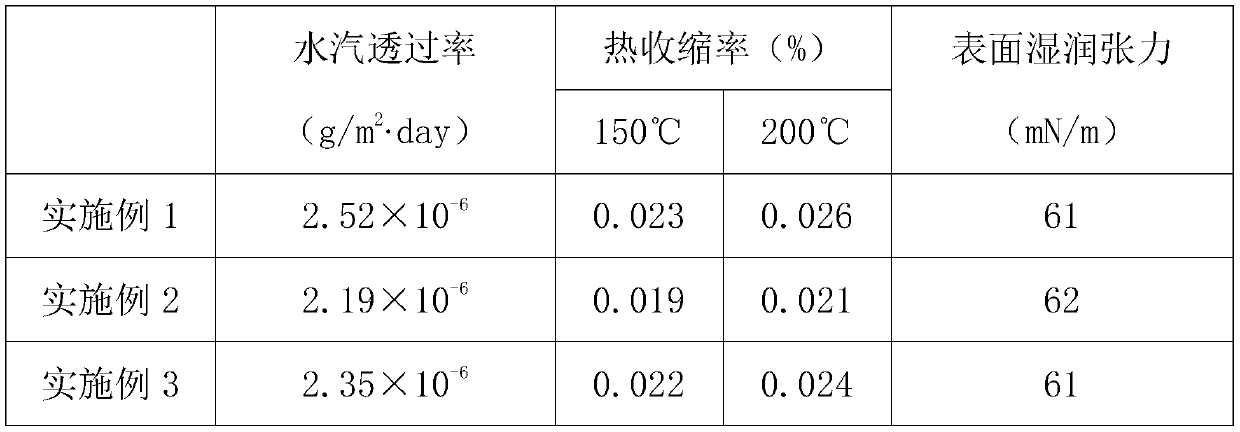

Embodiment 1

[0020] A high temperature resistant water vapor sealing film, the preparation raw materials of the sealing film include 20 parts of butyl acetate, 12 parts of polymethylpentene, 8 parts of polyimide, 6 parts of polyacrylate, 5 parts of modified Carbon nanotubes, 5 parts of inorganic high temperature resistant additives, 2 parts of glycidyl methacrylate and 1 part of dibenzoyl peroxide. Wherein, the modified carbon nanotube refers to the modified carbon nanotube obtained by acidifying the carbon nanotube with 70wt% concentrated nitric acid, the treatment temperature is 60°C, and the treatment time is 2h; the inorganic high temperature resistant auxiliary The agent is composed of silicon dioxide and magnesium stearate mixed, and the weight ratio of silicon dioxide and magnesium stearate is 2:1.

[0021] The preparation steps of the above-mentioned high temperature resistant water vapor sealing membrane include:

[0022] Step 1, mixing and stirring butyl acetate, polymethylpente...

Embodiment 2

[0027] A high temperature resistant water vapor sealing film, the preparation raw materials of the sealing film include 22 parts of butyl acetate, 13 parts of polymethylpentene, 10 parts of polyimide, 8 parts of polyacrylate, 7 parts of modified Carbon nanotubes, 6 parts of inorganic high temperature resistant additives, 6 parts of glycidyl methacrylate and 5 parts of dibenzoyl peroxide. Wherein, the modified carbon nanotube refers to the modified carbon nanotube obtained by acidifying the carbon nanotube with 70wt% concentrated nitric acid, the treatment temperature is 62°C, and the treatment time is 1h; The agent is composed of silicon dioxide and magnesium stearate mixed, and the weight ratio of silicon dioxide and magnesium stearate is 4:1.

[0028] The preparation steps of the above-mentioned high temperature resistant water vapor sealing membrane include:

[0029] Step 1, mixing and stirring butyl acetate, polymethylpentene, polyimide, polyacrylate, modified carbon nano...

Embodiment 3

[0034] A high temperature resistant water vapor sealing film, the preparation raw materials of the sealing film include 25 parts of butyl acetate, 15 parts of polymethylpentene, 12 parts of polyimide, 10 parts of polyacrylate, 10 parts of modified Carbon nanotubes, 8 parts of inorganic high temperature resistant additives, 12 parts of glycidyl methacrylate and 10 parts of dibenzoyl peroxide. Wherein, the modified carbon nanotube refers to the modified carbon nanotube obtained by acidifying the carbon nanotube with 70wt% concentrated nitric acid, the treatment temperature is 65°C, and the treatment time is 0.5h; the inorganic high temperature resistant The auxiliary agent is composed of silicon dioxide and magnesium stearate mixed, and the weight ratio of silicon dioxide and magnesium stearate is 5:1.

[0035] The preparation steps of the above-mentioned high temperature resistant water vapor sealing membrane include:

[0036] Step 1, mixing and stirring butyl acetate, polymet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com