Welding device for welding vertical girth seam of pressure vessel

A welding pressure and welding device technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of difficulty in ensuring welding seam welding quality, increasing the number of welding seam repairs, and high labor intensity of workers, so as to improve the service life, The effect of improving product grade and high degree of mechanical automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

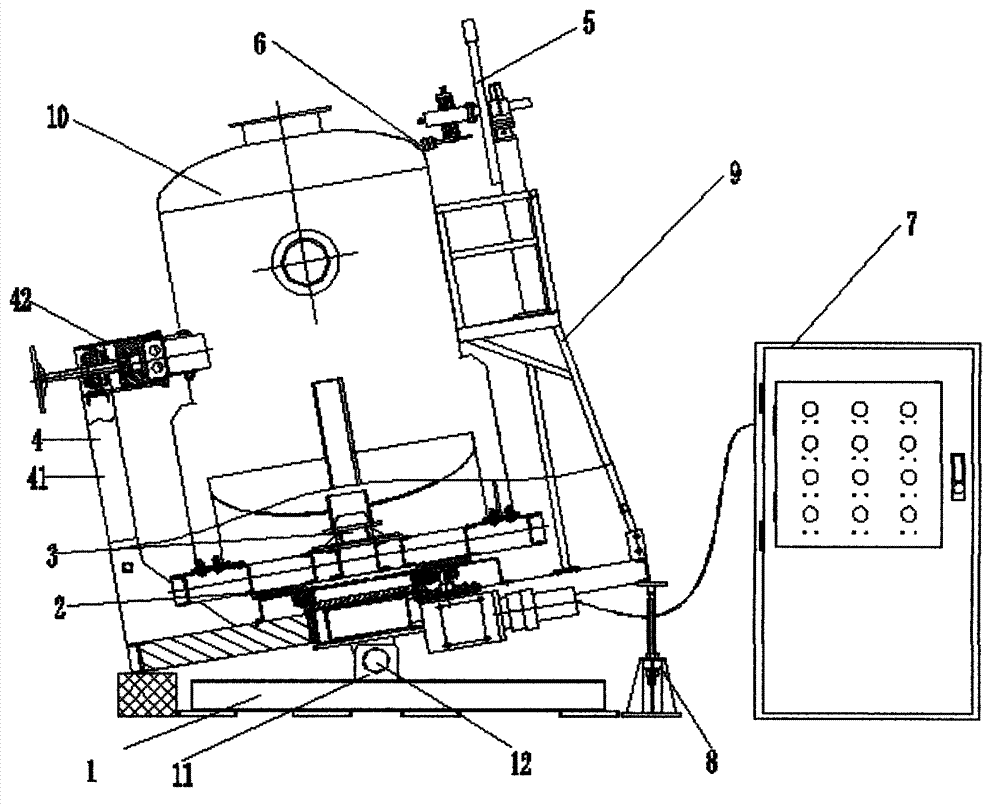

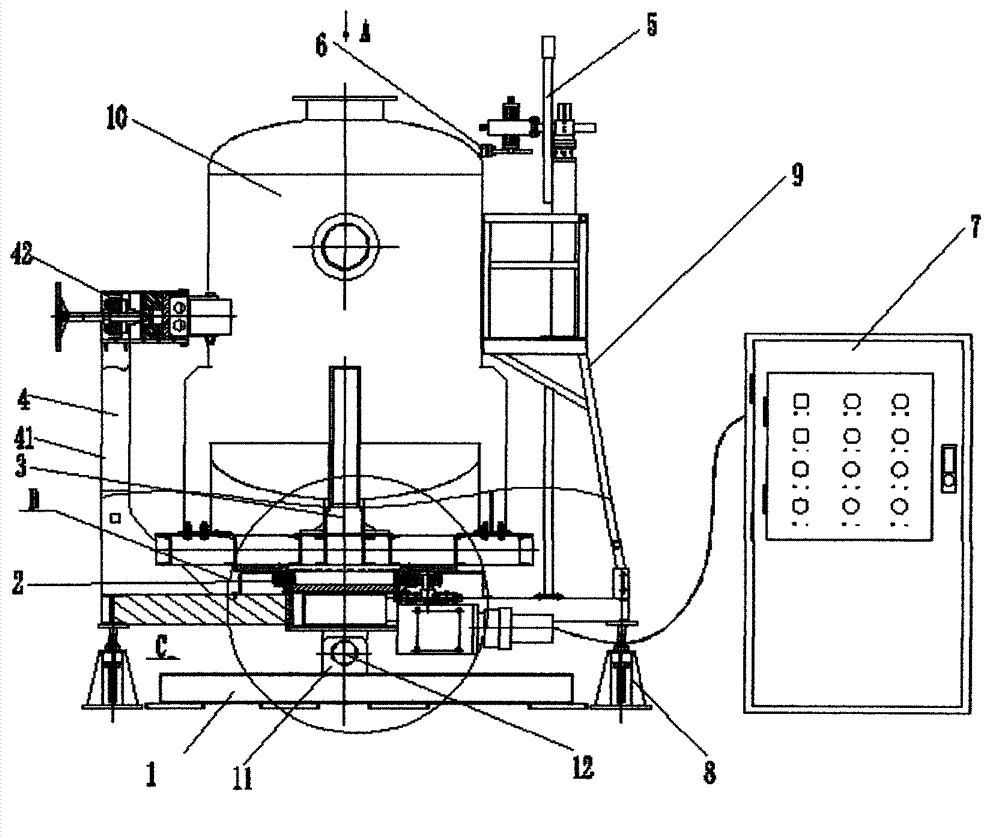

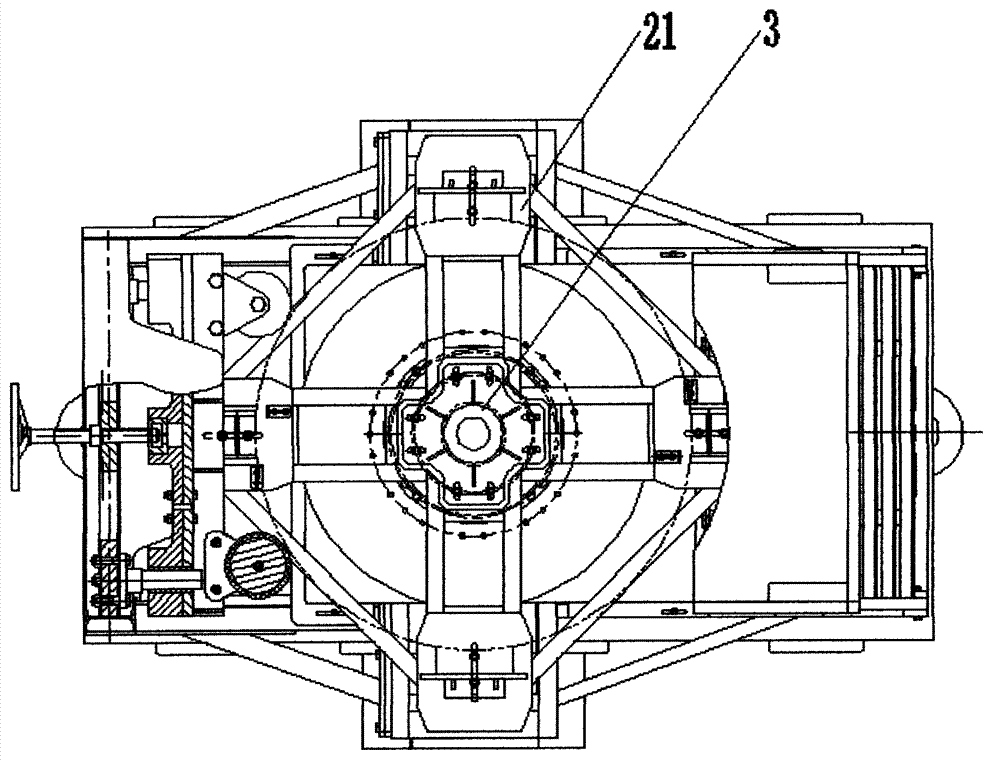

[0028] refer to Figure 1 to Figure 11 , the welding device for welding the vertical girth of the pressure vessel according to the present invention includes a base 1, a rotary device 2, a positioning device 3, a pressure vessel protection device 4, a welding torch clamping device 5, a welding torch 6, a control box 7 and a jack 8. A jack 8 is provided on the lower side of the base 1, and a support lug 11 is provided at the center of the base 1, and self-lubricating flanging bushings are installed on the support lug 11, and the slewing chassis 23 on the slewing device 2 (see Figure 7 ) and the lugs 11 of the base 1 are installed with the horizontal hinge shaft 12, the base 1 is placed flat on the level ground, and the rotary underframe 23 can tilt left and right with the horizontal hinge shaft 12 as the fulcrum, and the base 1 is formed by welding profiles and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com