Teflon extruder

A technology of extruder and Teflon, applied in the field of Teflon extruder, can solve the problems such as the loose coordination between the feeding screw and the screw cylinder, the unstable performance of the feeding screw, and the easy deformation of the machine head, so as to prevent glue burning, High work efficiency and stable head output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical content of the present invention, specific embodiments are provided below in conjunction with the accompanying drawings to further describe the present invention.

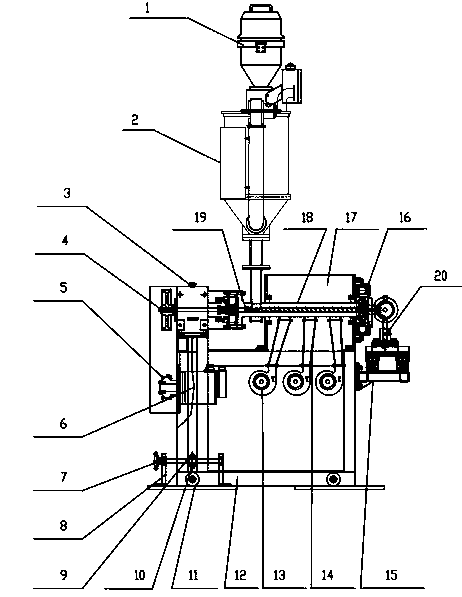

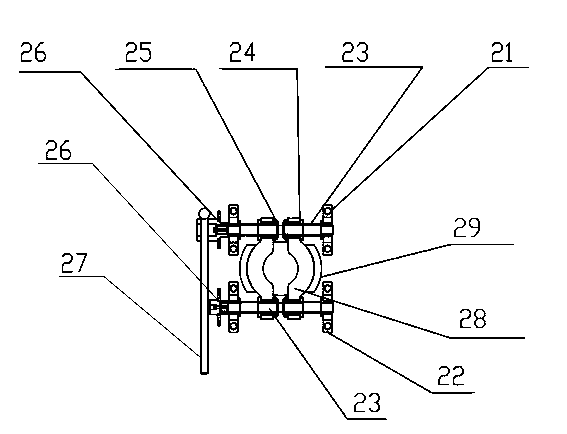

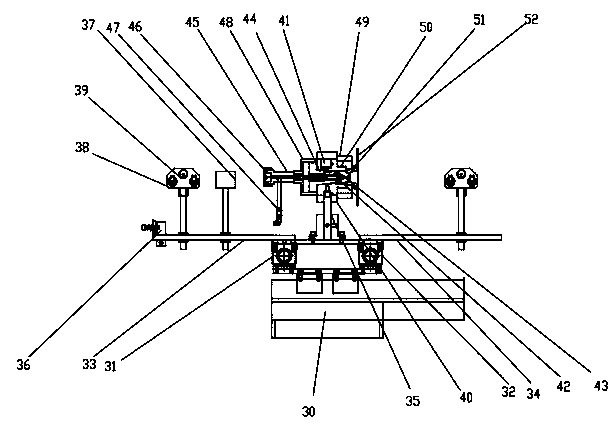

[0021] In this embodiment, refer to Figure 1 to Figure 3 As shown, a Teflon extruder includes a frame and an electrical system. A private motor 6 and a screw cylinder 18 are fixed on the frame. One end of the screw cylinder 18 is provided with a head clamp part 16. The screw cylinder 18 The other end is provided with a gear reduction box 3, the private server motor 6 drives the first transmission synchronous pulley 5, the first transmission synchronous pulley 5 drives the second transmission synchronous pulley 4 through the transmission synchronous belt, and the second transmission synchronous The transmission shaft of the pulley 4 drives the gear reduction box 3, and the gear reduction box 3 drives the feeding screw 19, and the feeding screw 19 is arranged in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com