Fast loading device for program control measuring

A program-controlled and remote-controlled technology, which is applied in the directions of packaging, loading/unloading, transportation and packaging, etc., can solve the problems of inconvenient loading and measuring methods, incapable of quantitative loading, and low measurement accuracy, so as to enhance long-term stability, Easy operation and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

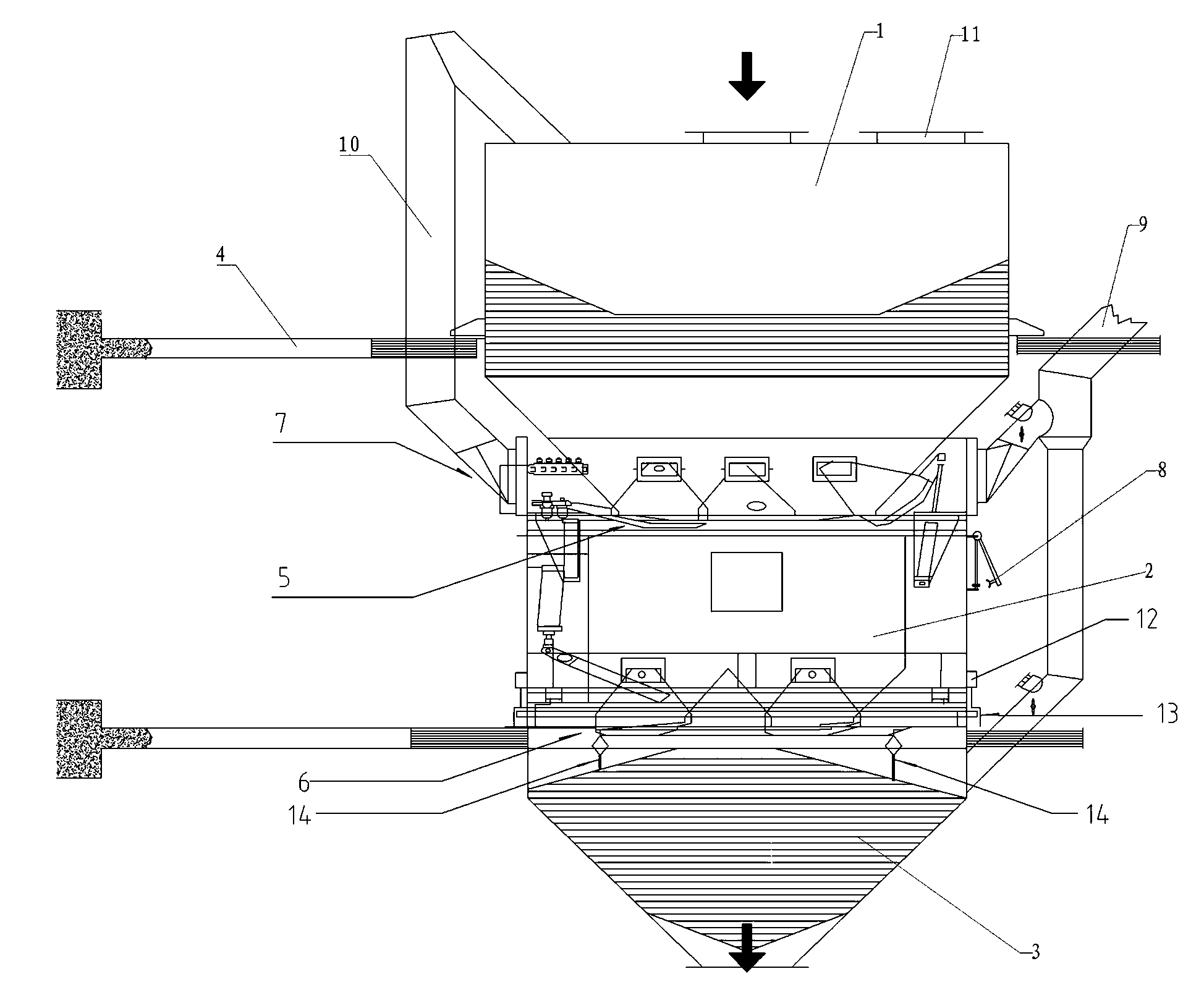

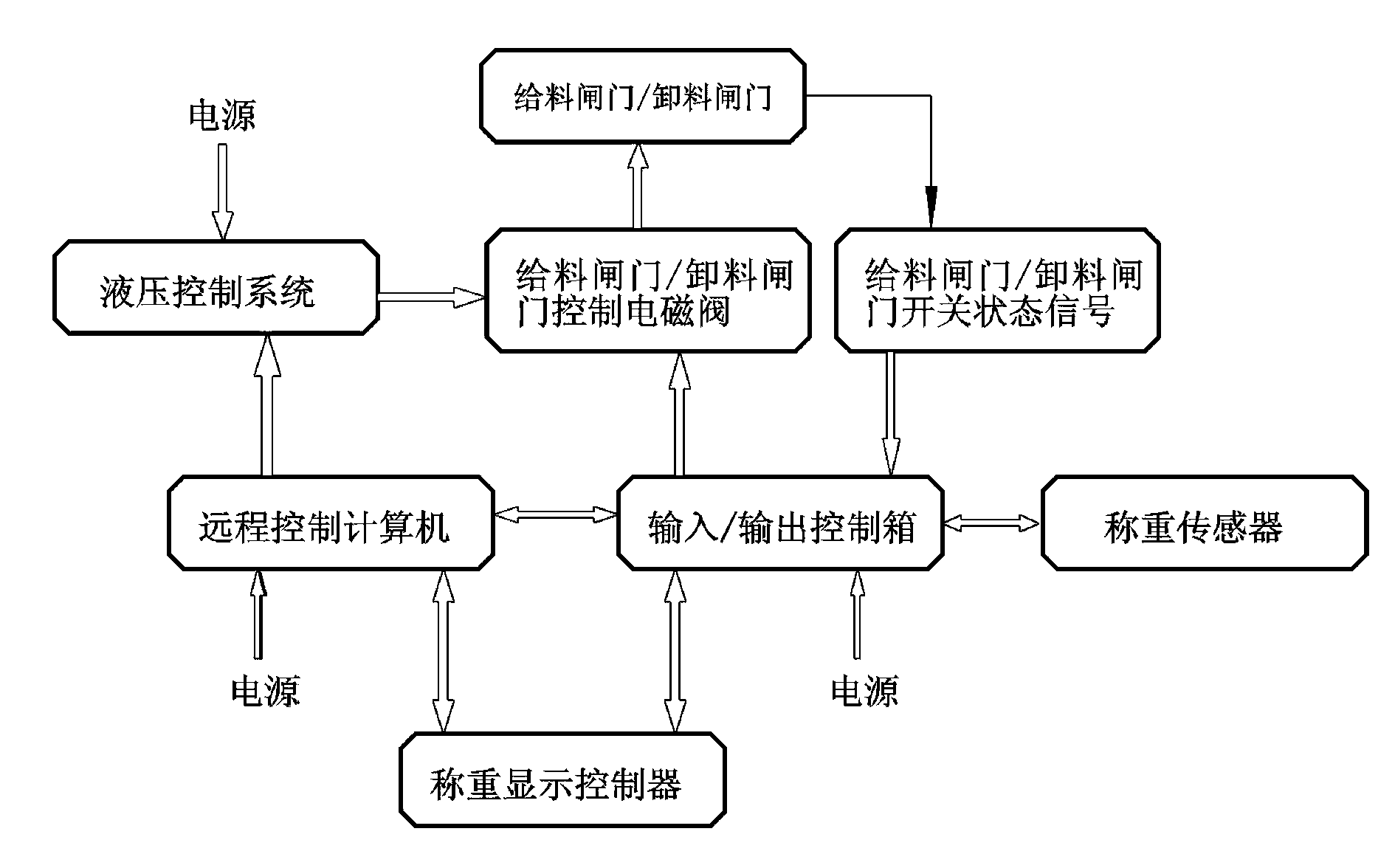

[0019] Embodiment one: see figure 1 , figure 2 , the program-controlled metering and quick-loading device of the present invention includes a storage hopper 1, a hopper weighing 2, an unloading hopper 3, a load-bearing frame 4 for supporting the storage hopper and the hopper weighing, and a control system, and the control system includes a feed gate 5, Discharge gate 6, hydraulic control system, input / output control box 7, weighing display controller and remote control computer, the feed gate is installed at the bottom of the storage hopper 1, and the discharge gate 6 is installed at the bottom of the hopper scale 2 , the feed gate and discharge gate are hydraulically driven, and a proximity switch is used to detect the switch state of the gate. The driving cylinders of the feed gate and discharge gate are connected to the hydraulic control system and installed on the storage hopper 1 at a remote The input / output control box 7 provides power for the load cell 12 at the botto...

Embodiment 2

[0030] Embodiment two: see figure 1, The program-controlled metering and quick-loading device of this embodiment is based on the first embodiment, a vibrator is installed on the hopper scale 2, and the control system includes a control circuit of the vibrator. In view of the characteristics of coal having a certain water content and poor fluidity, by installing a vibrator on the equipment, the scale body can be emptied to avoid the phenomenon of material accumulation.

Embodiment 3

[0031] Embodiment three: see figure 1 , The program-controlled metering and quick-loading device of this embodiment is different from Embodiment 1 or Embodiment 2 in that: further, an air balance pipe 10 is provided in cooperation with the storage hopper 1, and an air balance pipe 10 is provided in cooperation with the air balance pipe 10. The automatic vacuum door and its control mechanism, the control mechanism is controlled and connected to the control system, when feeding and unloading, the automatic vacuum door allows air to enter the balance pipe during dust discharge to compensate for the air pressure difference.

[0032] The program-controlled metering and quick-loading device of the present invention is provided with a soft connection filter cloth through the connecting parts of the storage hopper 1 and the hopper scale 2, and the hopper scale 2 and the discharge hopper 3, and is connected with the hopper scale 2 to be provided with a dust suction device 9, which can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com