A kind of anticorrosion coating for concrete surface and preparation method thereof

A technology of concrete surface and anti-corrosion coating, applied in the direction of anti-corrosion coating, epoxy resin coating, coating, etc., can solve the problems of human health impact, environmental pollution, etc., and achieve good anti-corrosion effect, good decorative effect and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

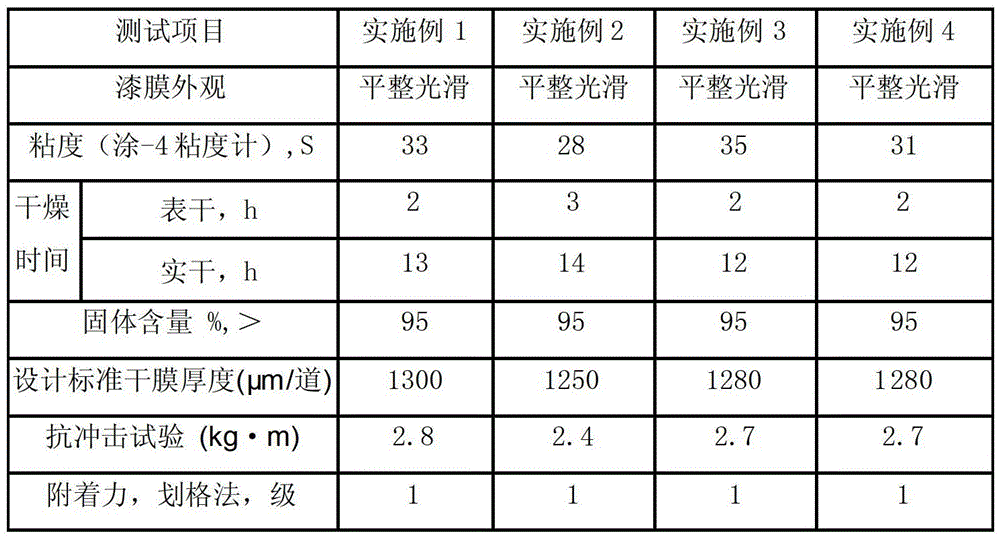

Examples

Embodiment 1

[0021] 1) Preparation of component A: Mix 80g of epoxy resin E-44 and 15g of dimethyl carbonate solvent in a reaction kettle, mix well after mechanical stirring, add 30g of talcum powder and 30g of sericite as a mixed filler, stir for 8 Minutes, then add 5g dioctyl phthalate, 4gKH560, 0.6gBYK-333, 8g butyl glycidyl ether, 7gWorlee_Add322, stir for 10 minutes until the mixture is completely mixed, and finally add 9g iron oxide red and continue stirring for 10 minutes, Disperse evenly, filter the filtrate to obtain component A;

[0022] 2) Preparation of component A: Mix 90g of epoxy resin E-44 and 20g of dimethyl carbonate solvent in a reaction kettle, mix well by mechanical stirring, add 35g of talcum powder and 35g of mica as a mixed filler, and stir for 8 minutes , then add 6gDOP, 6gKH560, 1.2gBYK-333 in turn, stir for 10 minutes until the mixture is completely mixed evenly, finally add 8g iron oxide red and continue stirring for 10 minutes, disperse evenly, filter the filtr...

Embodiment 2

[0026] 1) Preparation of component A: Mix 90g of epoxy resin E-44 and 20g of dimethyl carbonate solvent in a reaction kettle, mix evenly by mechanical stirring, then add 30g of talcum powder, 30g of sericite and 10g of white carbon black Mix filler, stir for 12 minutes, then add 8g plasticizer DBP, 1gKH560, 1.0g BYK-333, 5g butyl glycidyl ether and 5g benzyl glycidyl ether, 8g Worlee_Add322, stir for 15 minutes until the mixture is completely mixed, and finally add 13g of titanium dioxide continued to stir for 12 minutes, dispersed evenly, and filtered the filtrate to obtain component A;

[0027] 2) Preparation of component A: Mix 100g of epoxy resin E-51 and 25g of dimethyl carbonate solvent in a reaction kettle, mix well by mechanical stirring, then add 30g of talcum powder, 30g of sericite and 10g of barium sulfate Filler, stir for 10 minutes, then add 8g plasticizer DBP, 6gKH560, 1.2g BYK-333 in turn, stir for 15 minutes until the mixture is completely mixed evenly, finall...

Embodiment 3

[0031] Get 90g Epoxy Resin E-51 and 20g dimethyl carbonate solvent and drop in the reactor, after mechanical stirring mixes, the mixed filler that 30g talcum powder, 30g sericite and 10g white carbon black are formed adds reactor, stirs 12 minutes; Then add 8g dibutyl phthalate, 1gKH560, 1.0g BYK-333, 5g butyl glycidyl ether and 5g benzyl glycidyl ether, 8g Worlee_Add322 high-speed stirring for 15 minutes, finally add 13g titanium dioxide and continue stirring for 12 minutes, Disperse and filter evenly to obtain component A; take 30g of curing agent H-3302 and 12g of curing accelerator DMP-30 and mix them in a stirring device, and stir mechanically for 16 minutes until they are completely mixed and uniform to obtain component B; when using, mix component A Mix evenly with component B at a mass ratio of 3.2:1 to obtain an anti-corrosion paint primer for concrete surfaces.

[0032]Get 100g Epoxy Resin E-51 and 25g dimethyl carbonate solvent and drop in the reactor, after mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com