Quick filter system for wheat juice

A fast filtration and wort technology, which is applied in the field of beer production, can solve the problems of long mash filtration process and slow filtration speed of the filter tank, and achieve the effect of shortening working time, shortening working hours and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

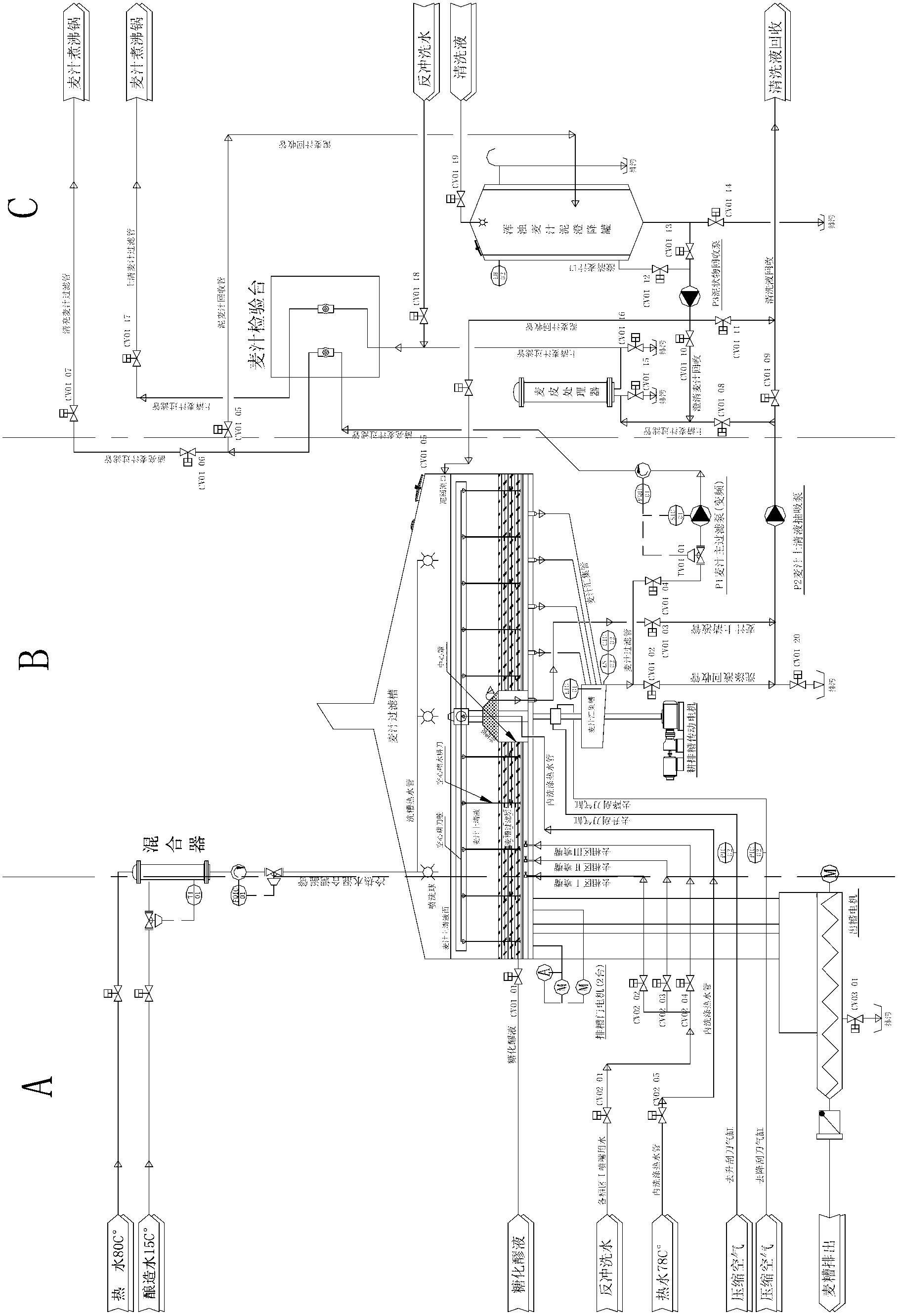

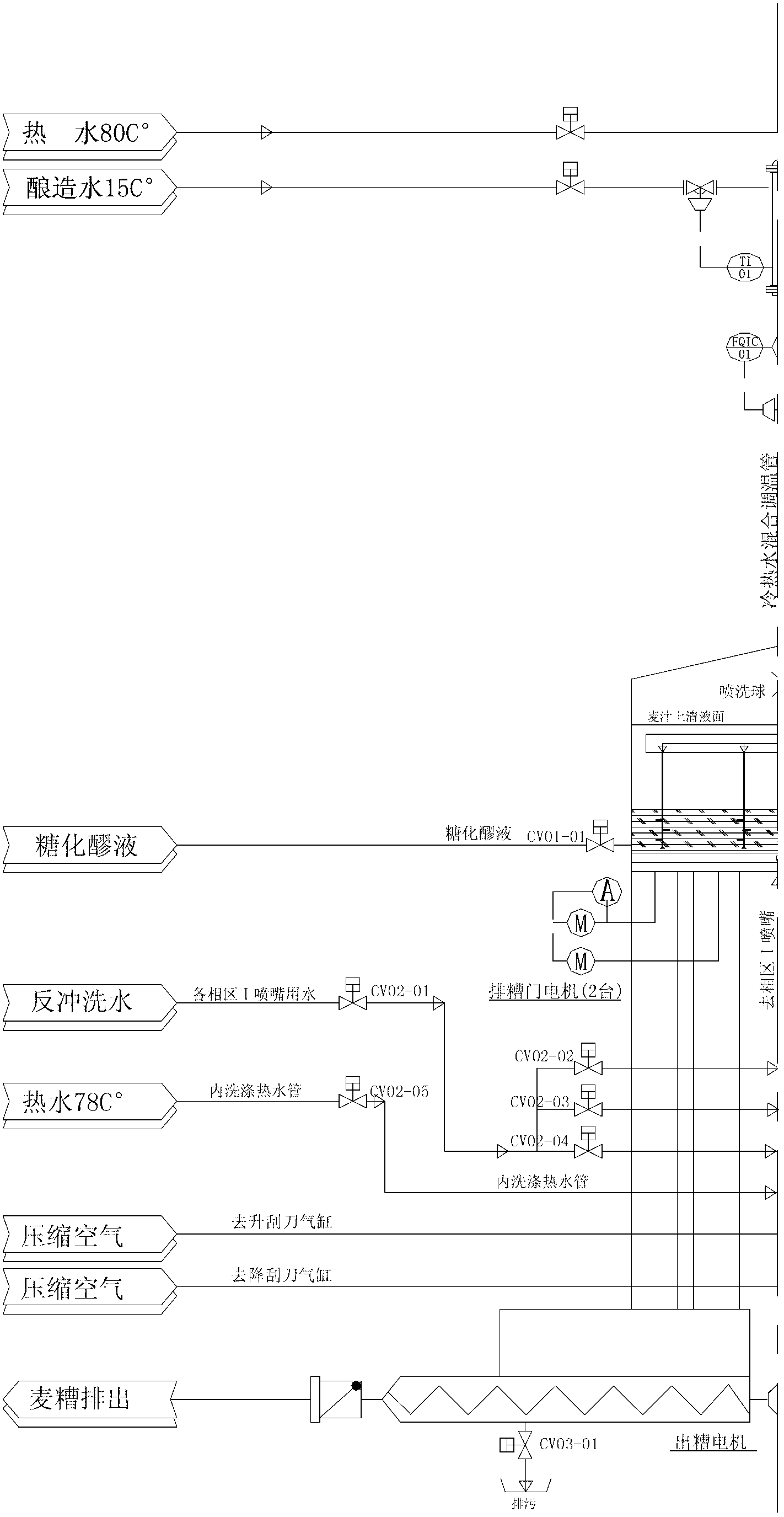

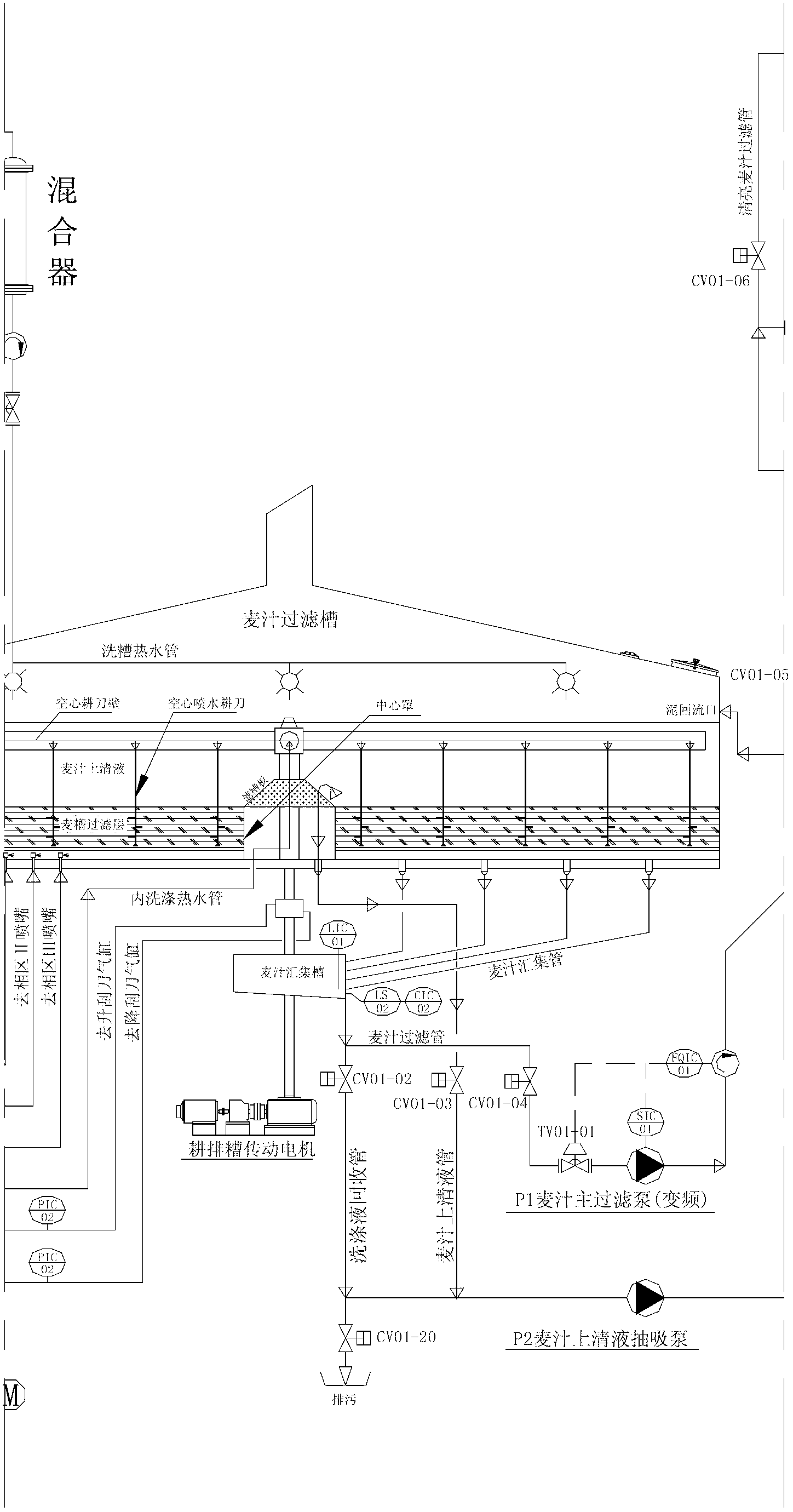

[0023] Such as Figure 1-5 As shown, a wort rapid filtration system includes a filter tank, and the feed part connected to the filter tank includes brewing water, cleaning water, mash and compressed air leading to a pneumatic scraping mechanism, and the output of the filter tank The wort discharge part includes the wort collection tank of the lauter tank, and the wort inspection table connected to the wort collection tank, and the liquid outlet of the wort inspection table is respectively connected to To the wort boiling pot and the turbid wort settling tank of the next process, the wort outlet part of the lauter tank also includes a bypass pipeline for directly discharging the wort supernatant, and the starting end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com