A kind of degreasing method of aluminum base for ctp plate production

An aluminum plate base and aluminum plate technology, which is applied in the field of degreasing the surface of aluminum and aluminum alloys, can solve problems such as nozzle or nozzle clogging, blue spot and blue spot, uneven degreasing, etc., and achieves large span and long film path Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

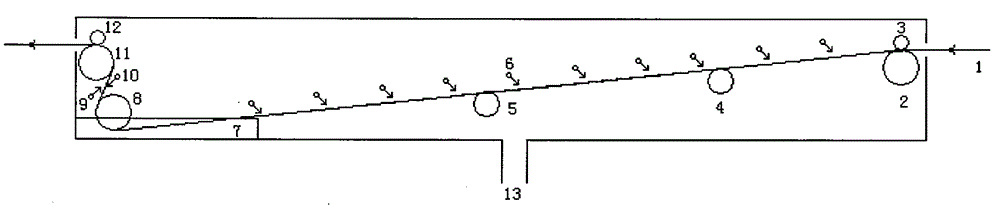

[0020] The temperature control and concentration control of the degreasing liquid are completed in the lower tank. After the pump and coarse filtration, the nozzle that hits the upper tank is sprayed to the front surface of the aluminum plate base through the upper nozzle hole, and flows into the small outlet end along the slope of the aluminum plate front After filling the small tank, it overflows to the upper tank for degreasing, flows back to the lower tank through the return pipe of the upper tank, and completes a tank liquid cycle; the front of the aluminum plate uses the spray method and the outlet end immersion method, due to the long reaction time , To be fully corroded; the back of the aluminum plate is only immersed at the outlet end. Due to the immersion method, the corrosion is uniform and the time is short, so the back of the aluminum plate is clean and maintains metallic luster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com