Rotor cutter seat component used on pavement milling machine

A technology for milling cutters and rotor cutters, which is applied in the field of rotor cutter holder components, can solve the problems that the cutter rod cannot rotate, reduce the service life of the cutter head, etc., and achieve the effect of convenient and quick disassembly, reasonable structure and guaranteed service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

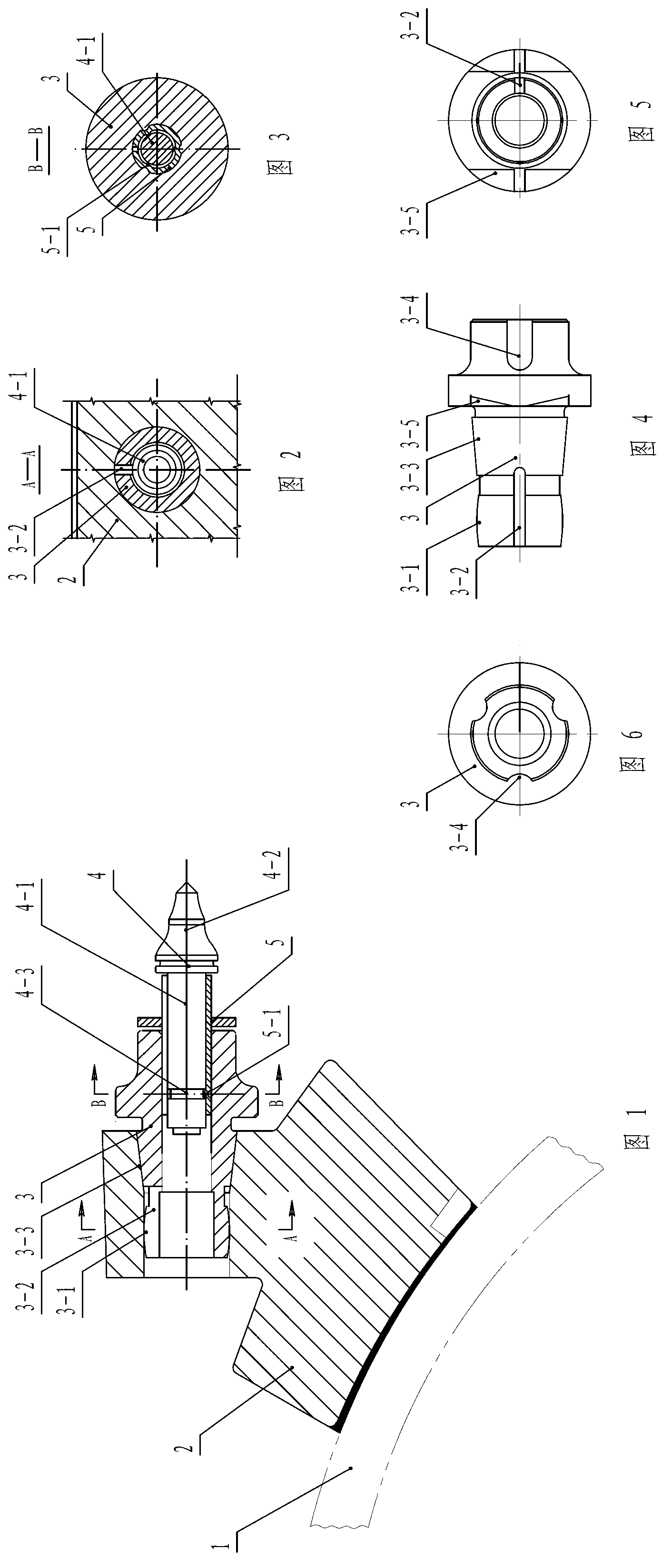

[0022] Such as Figure 1 to Figure 6 Shown: a rotor tool holder assembly used on a road milling machine, which includes: a milling cutter base 2, a cutter holder 3, an elastic opening fastening sleeve assembly 5 and a cutter 4. The cutter holder 3 is fixed on the milling cutter base 2 , and the milling cutter base 2 is welded on the milling cutter barrel 1 . Described knife cover 3 is tubular body, and the outer circle of knife cover 3 is made hook head wrench groove 3-4, open spanner surface 3-5 and conical surface 3-3; The conical hole connection of seat 2. The effect of the hook spanner groove 3-4 and the open spanner face 3-5 is to be used for easy installation and disassembly.

[0023] Described cutter 4 is made up of two parts of cutter bar 4-1 and cutter head 4-2, and described cutter bar 4-1 is installed in the inner hole of cutter holder 3 through elastic opening fastening sleeve assembly 5, and cutter bar 4 There is a gap between -1 and the hole wall of the elasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com