Experimental device for damage and failure process of high temperature and high pressure components

A high temperature and high pressure, experimental device technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of inability to expand process research, difficult direct testing, long time, etc., to achieve low test energy consumption and high degree of automation , the effect of small steam emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

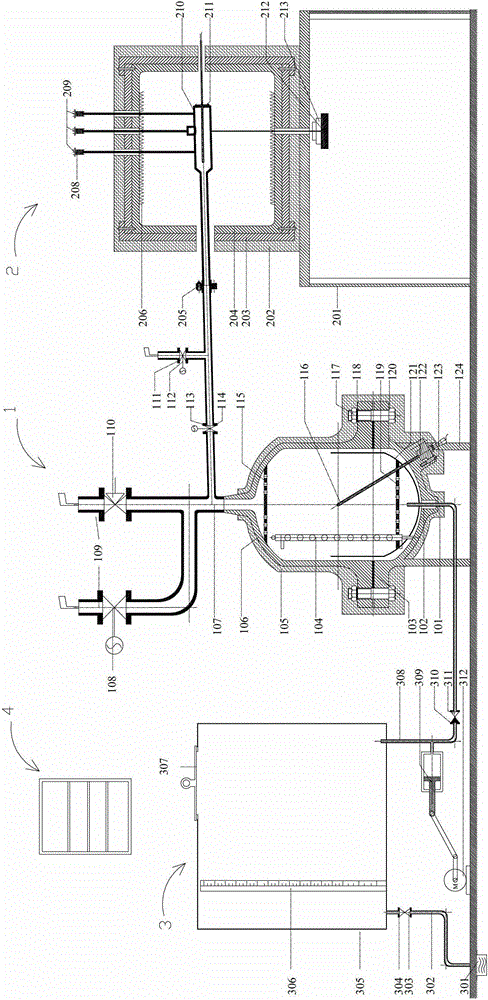

[0029] Implementation example: such as figure 1 As shown, the high temperature and high pressure component damage and failure process experimental device of the present invention includes four parts: steam generation system 1, specimen heating and testing system 2, water injection system 3, control monitoring and protection system 4.

[0030] The test piece heating and testing device 2 supported on the angle steel bracket 201 includes: from the outside to the inside, there is a closed box with a cover including a thermal insulation material layer 202, a steel plate material layer 203 and a refractory material layer 204, and a loading device 209 is arranged above the box. , which is connected to the test piece 210 through the spring 208 that extends into the box through the opening on the top of the box. The box is equipped with a resistance heating wire 206 to heat the outside of the test piece. There is a hole at the bottom of the box and a weight hook. 213, a weight 214 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com